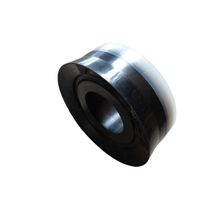

High Quality Reciprocating Piston Mud Pump Drilling Mud Pump Drilling Machine Mud Pump

-

Supplier: Shandong Aolai Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Mr Xi Tengfei -

Price: $1750.00 / 1 - 9 sets

$1700.00 / 10 - 14 sets

$1650.00 / >=15 sets -

Min. Order: 1 set

Product details

| port: | Qingdao, Ningbo, China | Supply capacity: | 100 sets per day |

| Water absorption height (m): | 2.5 | Core component warranty: | 1 year |

| Product number: | 250 type | Required power (Kw): | 15 |

| Pump speed (min-1): | 200 | Showroom location: | United Kingdom, Chile, Australia |

| Applicable industries: | Manufacturing plants, machinery repair shops, energy and mining, other | Health status: | new |

| Warranty: | 1 year | Package preview: | |

| Aperture (mm): | 80 | Packaging Details: | 1. Packed in wooden boxes and iron frames suitable for sea transportation 2. Wrapped with tarpaulins; 3. Full cabinet 4. Add wooden pallets. 5. According to customer requirements. |

| Mechanical test report: | Not available | Video shipment inspection: | Not available |

| Core components: | Pump | Flow (l/min): | 250 |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Stroke length (mm): | 100 |

| brand: | Outlet | Pressure (MPa): | 2.5 |

| Input speed (r/min): | 500 | Marketing Type: | New Products 2021 |

| type: | plunger pump |

BW250 mud pump refers to the machinery that transports mud and other flushing fluids into the borehole during the drilling process. Mud pumps are an important part of drilling equipment. In ordinary positive circulation drilling, the surface flushing medium—clear water, mud or polymer flushing fluid—under a certain pressure reaches the bottom of the well through high-pressure hoses, faucets, and the center hole of the drill string. The drill bit is used to cool the drill bit and transport the cut rock cuttings to the surface. Commonly used grouting machines are piston or plunger. The crankshaft of the pump rotates under the drive of the power machine, and the crankshaft drives the piston or plunger to reciprocate in the pump cylinder through the crosshead. Under the alternate action of suction valve and discharge valve, the purpose of pressure feeding and circulating flushing liquid is realized. BW250 (high-pressure grouting pump) mud pump is a horizontal three-cylinder reciprocating single-acting plunger pump with two cylinder diameters and four speeds. Displacement and hole depth can be freely adjusted according to the application. It can be used with a 1500-meter drilling rig, and can also be poured with cement. The pump consumes less energy, operates flexibly, is durable, has good decomposability and is easy to move.

Product Description

BW series mud pumps are used in geological drilling, supply flushing fluid (mud or clear water) to cool drilling tools, dilute clay, mud and circulate. Pressure grouting can also be used for coal seam emergency sealing grouting, coal slurry transportation, sewage suction, cement slurry grouting reinforcement, and can also be used for other purposes such as grouting, mine drainage, and long-distance water delivery. In above-ground projects, it can also be used for construction reinforcement, water blocking grouting, smooth grouting between the pipe surface and soil in pipe jacking construction, high-pressure backfilling, building construction, etc. The conveying liquid flow is stable, without overcurrent, pulsation, stirring and shearing. The mine mud pump has a simple structure and is easy to maintain. It is a variable-strength pile made of crushed stone, stone chips, fly ash mixed with cement and water, and then used to make piles. It is a pile type between rigid pile and flexible pile. Fly ash, stone chips, etc. can be used as admixtures, which can effectively reduce the project cost. Long auger drilling and in-pipe pumping of mixture into piles, suitable for clay soils.

product specification

Product model: 250 type |

Type: plunger pump |

Stroke length (mm): 100 |

Aperture (mm): 80 |

Pump speed (min-1): 200 |

Flow (L/min): 250 |

Pressure (MPa): 2.5 |

Required power (Kw): 15 |

V-belt pulley pitch circle diameter (mm): 410 |

Input speed (r/min): 500 |

Water absorption height (m): 2.5 |

Inlet pipe diameter (mm): 76 |

Drain pipe diameter (mm): 51 |

Dimensions (mm): 1100*995*650 |

Weight (kg): 760 |

According to the number of cylinders of the pump: according to the number of cylinders of the pump, there are single cylinder, double cylinder, triple cylinder, five cylinder, etc. The main components of the slurry pump are composed of pump casing, pump body, impeller, pump base, coupling, support cylinder, clutch, gearbox, power drive, motor base, motor, pressure gauge, cleaning valve and other components. The volute, pump seat, motor seat and impeller nut are cast iron parts, which have good corrosion resistance and convenient processing technology. The impeller is a three-piece single circular chord arc blade, which adopts semi-closed impeller and malleable cast iron, which has high strength and corrosion resistance; it is easy to process, has good permeability and high efficiency. In order to reduce the weight and reduce the amount of turning, the pump shaft is made of high-quality carbon steel cold-drawn steel. The pump base is equipped with a four-frame oil seal and a shaft sleeve to prevent shaft wear and prolong shaft life.

VIEW MORE

You may like

-

Mud pump accessories hydraulic cylinder liquid end module

-

high flow F800 valve ideco hydraulic api three cylinder bomco price integrated piston mud pump for drilling rig

-

Brand New Stainless steel pipe flange Stainless steel flange bushing

-

API Standard 3NB Series Oilfield Drilling Mud Pump

-

Pulsation dampers and bladder pulsation dampers for API mud pump components

-

8HP Diesel Engine Cement Slurry Pump for BW-160 Drilling Rig

-

F500 mud pump

-

Beyond Supply BW250 BW450 BW800 Piston Rubber Assembly Drilling Mud Pump Spare Parts

-

BW250 powerful small three-cylinder mud pump drilling mud pump for sale

-

API New Drilling Rig Spare Parts API BW150 Triple Mud Pump

Other Products

-

$2800.00 - $3380.00 / set

$2800.00 - $3380.00 / set -

$2050.00 - $2450.00 / set

$2050.00 - $2450.00 / set -

$2800.00 - $2900.00 / set

$2800.00 - $2900.00 / set

Related Search

high quality oil drilling mud pump valve assembly suppliers

triplex reciprocating piston pump high pressure

piston mud pump

high quality hex head self drilling

high quality self_drilling screws

electric fuel pump high quality

high quality electric water pump motor price in pakistan

high quality hammer drill suppliers

high quality electric concrete pumps

high quality desoldering pump suppliers