Oscillating Granulator Yk-60 Yk90 Yk160, Yk60 Pharmaceutical Oscillating Granulator/YK-160 Pendular Granulator

-

Supplier: Shanghai Tianfeng Pharmaceutical Machinery Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Winni Kong -

Price: $200.00 /set -

Min. Order: 1 set

| Machine Type: | Granulator; | Packaging Detail: | wooden case/plywood; Or with container based order quantity; |

| Warranty: | 1 Year; | Certification: | CE ISO; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support,Engineers available to service machinery overseas; | Power (kW): | 0.55; |

| Supply Ability: | 56 Set/Sets per Month; | Output (kg/h): | 30; |

| Brand Name: | tianfeng; | Place of Origin: | Shanghai China; |

| Port: | shanghai port; | Voltage: | 220V/380V/depend on customer; |

| Applicable Industries: | Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Food & Beverage Shops; | Package Preview: | ; |

| Condition: | New; | Product Type: | Detergent Powder; |

| Weight (KG): | 150; | Dimension(L*W*H): | 750*460*840mm; |

| Payment Terms: | L/C,D/P,T/T,Western Union,MoneyGram; |

Model | YK60 | YK90 | YK160 |

DIA rotor(mm) | 60 | 90 | 160 |

Capacity (kg/h) | 20-30 | 50-100 | 200-300 |

Rang of wave | >360° | >360° | >360° |

Number of times of waving rolingly | 46 | 50 | 55 |

Motor power(kw) | 0.25 | 0.55 | 2.2 |

Weight (kg) | 55 | 150 | 330 |

Overall size(mm) | 460*550*570 | 750*460*840 | 970*560*1240 |

Main application:

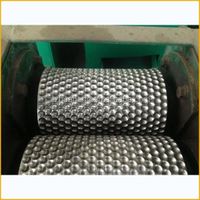

This machine is used mainly in such trades as pharmacy, chemical industry, food, pottery and plastics extensively, making moist powder material particle. Make cylinder swing reciprocatly, extruding material from screen mesh for granulation.

Uses for machine

1.This machine makes use of the rolling motion of rotating barrel, granulates the wet powder materials into granule by sieve, it also can be used to crush agglomerate materials into small granules directly.

2.In chemical medicine field, it can be used for granulating the mixed powder into granule, and compressed into tablet after being dried, it also can be used for granulating the coagulated material that is formed during storage or during chemical processing, In food industry, it can be used to deal with the candy and sugar mixture as well as barley milk products. In other industries, it can be used to granulate such as porcelain and plastic mixtures into forming granules.

3. It is not suitable for solid, fluid medium, paste or pulverizing.

4.The mesh number of sieve should be prepared by users, according to the size of granule.

1. L/C at sight;Paypal,western union,by Alibaba and so on

2. T/T: 30% deposit by T/T, 70% balance by T/T before shipment

Trade term:EXW, FOB,CIF

Packing detail

We can provide wooden case or according to customer’s requirements.

Delivery time about 15-30 days after received order

F. Mechanical Lubrication

Reducer box can store oil, worm splashes to lubricate various transmission parts, depending on the mirror surface lines engraved on the oil. There is oil plug in box rear for discharging oil. Open the cover, adding lubricants in middle and back bearing, adding lubricant grease in the within bearing seat. The use of lubricants and grease as following:

No. | Lubrication parts | How often | Lubricants and lubricants grease |

1 | Front beating | Every shift | HJ-30 Lubricating oil |

2 | Middle and back bearing | Every three months | ZG-2 Grease |

3 | Reducer box bearing | Every three months | HJ-30 Lubricating oil |

H. Installation

1.This machine is packed in the wooden case, when you disassembly the wooden case, just put the machine in the appropriate place and flat pad so that you can use it.

2.Electrical wiring devices is not restricted by the direction of rotation, the wiring is under the base, through the belt cover to connect with the switch, cable cards clamping.

I. Introduction of uses

1.Usage: Operation the machine, pouring the mixing materials into the hopper, it makes use of the rolling motion of rotating barrel, granulates the powder materials into granule by sieve. Such as crushing blocks, you should gradually adding the blocks into the hopper, not to put too much in order to avoid excessive pressure, and cause the sieve become vulnerable.

2.Note: If the powder stops to put into the hopper, you can not use shove, so as to avoid injuring hands, you should use bamboo or stop the machine.

J. Maintenance

1.Regularly inspect the machine, once every month. Check if there is flexible and wear of the worm gear, worm and bearing and other parts. If you discovery defects, you should timely repaired them, and stop to use.

2.This machine should be placed in dry and clean indoor, in the atmosphere must not contain acids and corrosive gases, which will damage the machine.

3.After you use the machine, you should remove the roller barrel for cleaning, and brush the remaining powder, and then set properly to prepare for the next time use.

4.If you will long time no to use this machine, you should wipe and clean the whole machine body, coated with anti-rust oil in the surface of machine, and cover with cloth.

Description

It is developed on the basis of the international advanced technologies. It is featured by its low material waste, reasonable structure, easy operation, compact size, large compression, low noise, small weight deviation, adjustable tablet filling depth and thickness, etc. With all of its functions at the level of the similar imported products, this single press machine can be widely used in pharmaceutical, chemical, electronic, foodstuff and more industries for pressing the powder or granular materials into tablet automatically in a continuous way.

Certificate details

1.how many days will you ship machine ?

normally if you buy tablet press machine or packing machine ,machine will be assembled mold ,and we produce it according to customer request ,it may spend 10-15 days ,if we have in stock ,it will be sent within one week after receiving customer payment.

2.what is your pacakage type?

we export machine to abroad ,packing it with wooden case,export plywood,and stick the shipping mark.

3.Are you trading company or manufacture in China ?

My company is in Shanghai ,China .we export machine to all arround of the world every year,and we have factory which located in Songjiang district,Shanghai,China.and we have exambition 3-4 times every year.

One station service to make sure our customer get good products and good service.

(1) Professional advice and rich experience help to choose machine.

(2).Warranty time: All machines are guaranteed for one year.

(3).Any problem: If you have any questions or any demands, we will reply you within 24 hours

except the special reasons once you enquiry us.

(4) Additives: installation book, Manual book, tool box will be sent with machine.

Product Quality

All products are guaranteed for one year, if any problems happen in guarantee period, our company will maintain for free.

Spare Part Replacement

First round mould for free, discount if more order.

Technical Service

We can provide design, installation and debugging services or remote maintenance teaching.

Delivery The Cargo To Nearest Port

We will arrange the shipment and delivery the cargo to your nearest port, save time and cost.

Detail Product Information

Provide picture, video, instruction and product brochure.

Reply Timely

24 hours hot line ,we will reply email within 12 hours.

-

Chicken manure granulator fertilizer/twin roll extrusion granulator fertilizer for sale

-

Industrial large capacity ZL rotary dry granulator granulator mixing granulator food powder processing production line

-

Ganulator Machine Chemicals, Minerals, Inorganic Powder Granulator Fertilizer Double Roll Press Machine Customized 15kw, 30kw CN; JIA 1t

-

Cat litter bentonite granulator/dry powder granulator

-

Organic fertilizer granulator

-

Latest Design Urea Fertilizer Production Equipment

-

1000-1800 kg organic fertilizer bentonite pellet machine per hour

-

Fully automatic urea fertilizer plant/NPK fertilizer production line fertilizer machine

-

Disc Granulator Fertilizer Disc Granulator

-

High quality organic npk compound fertilizer making machine drum granulator for sale

Other Products

-

$1500.00 / unit

$1500.00 / unit -

$3580.00 / unit

$3580.00 / unit -

$1200.00 / set

$1200.00 / set