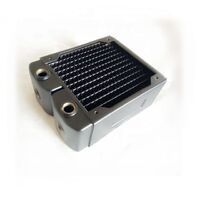

brazed plate heat exchanger

-

Supplier: Jiangmen City East-Alliance Thermal Equipment Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Jonson Ge -

Price: $370.09 /piece -

Min. Order: 1 piece

| After-sales Service Provided: | Online support; | Processing Types: | Milk; |

| Processing: | Heat Exchanger; | Model Number: | EATB50-86; |

| Selling Units: | Single item; | volume per channel: | 0.14 L; |

| welding material: | copper; | Place of Origin: | Guangdong China (Mainland); |

| Package Type: | plywood box or carton box; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| Brand Name: | Alliance; | certification: | ISO9001/ISO14001; |

| Certification: | CE; | Single gross weight: | 32 KG; |

| Warranty: | 1 Year; | Delivery Detail: | 0 days after payment; |

| Single package size: | 58X17X31 cm; | production type: | brazed plate heat exchanger; |

| Power(W): | 125,000 W; | MOQ: | 1; |

| port size: | 1 1/2"; | effective area: | 5.21 m2; |

| Voltage: | available; | Dimension(L*W*H): | 540mm*126mm*248mm; |

| package: | plywoods carton; | raw material: | SS316/SS304; |

| Weight: | 24 kg; | Condition: | New; |

| temperature: | -160 C ~ 200 C; |

| brazed plate heat exchanger | |

| Series | EATB50 |

| Design pressure(Mpa) | 1.0 or 3.0 |

| Lowest working temperature | -180 |

| Hightest working temperture | 200 |

| Heat transfer area per plate | 0.062 |

| Volume per channal(L) | 0.14 |

| Cross-sectional area per channal | 0.00030 |

| Plate material | SS316L/304L |

| Welding material | 99.9% COPPER |

| Height(mm) | 540 |

| Width(mm) | 126 |

| Thickness(mm) | 2.76×N(number of plates)+8 |

| Weight(Kg) | 0.25×N(number of plates)+3 |

| Applications | 1,Used in various fluid media:all type of refrigerants(R410a,R407c,R404,R134a,R22,R23,etc),oil,water,water and glycol mixtures. 2,Used in various equipment:hot pumps,industrial water cooling machines,plastic injecting machines,welding machines,oil pressure machines,compressors(circulation oil),air conditioners,refrigerators,air dryer,water cooler,drinking thoughts,constant temperture refrigerator,heat recollection and circulation,floor heating,indoors and outdoors heating devices |

| Features: |

| 1. High-efficiency: The combination of fluid turbulence technical features than the traditional shell and tube heat exchanger 3-6 times more efficient heat transfer. |

| 2. Small size, light weight: only equivalent to the shell and tube heat exchanger of 20-30%, greatly reducing the design of the installation space, so that the entire structure of the unit more compact, more reliable quality. |

| 3.High-temperature, high pressure: the metal material determines its own with high-temperature (up to 400 ° C) and pressure (the pressure of work 30BAR, can be enhanced 45BAR). |

| 4.Low-cost: heat exchanger than the average cost-saving materials, and to save installation space and reduce overall design costs. |

| 5. Corrosion-resistant: good corrosion resistance. |

| 6. To facilitate the installation of: fixed a variety of ways, easy to install. |

| 7. Quality: the industry leader in advanced technology and years of practice experience in production, the cast of high-quality products. |

| brazed plate heat exchanger consist of stainless steel plate packs, which have embossed chevron patterns. The plates are turned 180 degrees to each other, causing the plate ridges to intersect and creating a lattice of intersecting channels. Fluids can flow in counter-current and co-current way. The entire construction is nondismountable and scaled together by means of brazing in a special vacuum furnace. |

| Major advantage over a conventional brazed plate heat exchanger in that the fluids are exposed to a much larger surface area because the fluids spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. brazed plate heat exchanger are now common and very small brazed versions are used in the hot-water sections of millions of combination boilers. The high heat transfer efficiency for such a small physical size has increased the domestic hot water (DHW) flowrate of combination boilers. The small brazed plate heat exchanger has made a great impact in domestic heating and hot-water |

| How brazed plate heat exchanger Works: |

| Heat transfer occurs when there is a difference in temperature between two mediums. Heat will travel from the hot source to the cold source. The rate at which the heat transfer occurs at is determined by many factors such as the heat conductivity of the two materials andthe difference in temperatures of the two mediums. Convectiuve heat transfer occurs when the materials are moving against each other |

| Corrosion protection for brazed plate heat exchanger stainless steel has a high resistance to most chemicals but is sensitive to chloride ion concentration so this must be limited to 280ppm or less(lower than 55 C),the copper used in the brazing process is mainly sensitive to strong acid and ammonia so the PH must be maintained between 6 to 8.in practical application.for example,hydrochloric acid should never be used to clean the brazed plate heat exchanger;if brazed plate heat exchanger are applied in seimming pool heating,limite chloride ion concentration to 280ppm in the water;what's more,in chemical,pharmacy and other industries,solutions containing strong acid like hydrochloric acid and harshorn won't be proper fluid medium. |

| Applications for the brazed plate heat exchanger: |

| This is an extremely popular unit for wood burning furnaces, radiant floor systems, refrigerant systems, straight vegetable oil conversions, beer chilling, air conditioning system and solar water heating systems. It will work for any application in which the desired result is for two fluids (liquid or gas) to exchange heat. |

| East-Alliance Thermal Equipment Co.,Ltd, a HK-funded enterprise located in Chaoyang Industrial Zone of Jiangmen City in Guangdong Province,China,belong to Guangdong DongXu Group. The Company has been specializing in brazed plate heat exchangers manufacture and sales, which are widely applied to the fields involved in cooling, heating, oil pressure, vessel, electric power, paper making, metallurgy.etc. |

| The company possesses a complete set of professional production and detection equipments such as the stamping equipment, the vacuum brazing furnace and the high-vacuum helium leak detector, etc. Our mold design and development as well as the plate exchanger technology and application had achieved an international leading level. |

| As a Guangdong Province private technology enterprises,the products have complete independent intellectual property rights, Obtained many the national invention patents , obtained the national technological innovation fund specialized to science and technology enterprises.It has been manufaturing high quality products with imported stainless steel by the most advanced vacuum welding furnace ensuring the first grade quality. |

| The company has been constantly carrying out the Quality Managenment System Standard of ISO9001:2000 and had passed the PED/CE and Rosh Certification to export to EU,by means of our high quality and elaborate products together with our professional and fast service,we are dedicated to satisfying the needs of all our clients worldwide |

Q1. Where can I use EATB HE?

A1. EATB HE are suitable for almost any refrigerant-to-liquid or liquid–to-liquid application but without corrosive media, such as ammonia or seawater. Please see §6

Q2. Can I turn the unit around?

A2. Yes, all the EATB HEs are possible for all applications.

Q3. Can I use a EATB HE in swimming pool application?

A3. Yes. It is important to add the chloride after EATB HE, to avoid the risk of an unbalanced lever of chloride in the water passing through EATB HE. Nevertheless a stronger chloride will react with the copper, which is obviously not good for EATB HE unit.

Q4. Can I use a EATB HE in a steam application?

A4. Yes. We strongly recommend to respect the four aspects:

l A free exit on the condense side avoids possible shocks

l Steam inlet has to be at the “marked side” on the upper connection. The “marked side” has once channel less and the steam will therefore be surrounded by the liquid side.

l Avoid formation of steam bubbles by adjusting the pressure on the secondary side correctly.

l Avoid temperature differences over 50℃ in the start up procedure. When EATB HE is in operation the temperature difference can be increased.

Q5. If the EATB HE was dropped on the floor or got other physically damaged, how can I be sure it is still OK?

A5. To be 100% sure you have to determine the same test as East-Alliance does to verify the right quality of the unit, see §2.4.

Q6. When we tested the unit it is no longer tight. Can we solder the unit on the outside and make it tight?

A6. Alliance does not recommend repair soldering. If the customer, nevertheless, wants to try to repair the unit, a silver soldering of 45% should be used. Obviously there is no guarantee for a good result.

Q7. Can I use de-ionised water in the EATB HE?

A7. It is no problem for EATB HE itself to use de-ionised water. There might be a problem though, with the application, as the copper will react with the de-ionised water.

Q8. Won’t the smaller passages in a EATB HE foul up easily?

A8. No, EATB HE is less prone to fouling than tubular type heat exchangers. Fouling occurs when there is low fluid velocity (laminar flow) and uneven distribution of flow among the passages. The unique design of a EATB HE allows the heat exchanger to operate at extremely low velocities while maintaining turbulent flow. Furthermore, the internal design assures a well distributed flow over the heat transfer surface.

-

Dairy SS304 500L 1000L Milk Pasteurization Plate Heat Exchanger 1000L

-

VT04 VT10 VT20 VT40 Milk pasteurization machine SS316 plate heat exchanger

-

Heat pipe heat exchanger

-

ASME industrial titanium tube heat exchanger shell tube/heat exchanger steel tube shell/aquarium chiller evaporator

-

ASME shell and tube heat exchangers, titanate pressure vessels, columns, steel reactors and complete pre-assembled units

-

Heat exchanger for food safety food grade milk dishes

-

Glass condenser

-

hot sale copper radiator 360 radiator small heat exchanger

-

Manufacturer 120 Copper Tube Heat Exchanger Copper Radiator

-

120/240/360/480 Copper and Brass Liquid Heat Exchangers