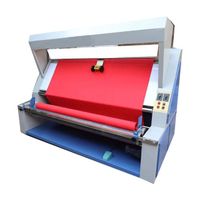

SUNTECH fabric inspection rolling machine Textile Checking Machine

-

Supplier: Zhejiang Strength Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Mindy Dong -

Price: $3500.00 /set -

Min. Order: 1 set

| Warranty: | 13 Months; | Speed: | 5-60m/min; |

| Automatic Grade: | Automatic; | Edge-alignment Error: | Less than 6mm; |

| Certification: | CE; ISO9001; | Condition: | New; |

| Product Name: | SUNTECH Length Counting Woven Rolling Fabric Inspection Machine; | Fabric Width: | 1800-4000mm; |

| Brand Name: | SUNTECH; | Fabric Type: | All Fabrics; |

| Roll Diameter at Output: | 500-1400mm; | Power: | 1.1kw(for ST-WFIM-180 only); |

| Dimension(L*W*H): | 3050*2630*2430mm; | Fabric Output Form: | Plaited or Roll; |

| Applicable Industries: | Manufacturing Plant,textile industry; | After-sales Service Provided: | Free spare parts,Video technical support,Online support,Field installation, commissioning and training,Field maintenance and repair service,Engineers available to service machinery overseas; |

| Weight: | 1000kg(for ST-WFIM-180 only); | Payment Terms: | L/C,D/A,D/P,T/T,Western Union; |

| Roll Tension Controlling: | Yes; | Supply Ability: | 100 Set/Sets per Month; |

| Fabric Input Form: | Plaited or Roll; | Voltage: | 3 Phase-380V; 50Hz; |

| Packaging Detail: | Steel Pallet or Wooden Box Packing; | Place of Origin: | Zhejiang China; |

| Port: | Ningbo or Shanghai Port; |

Product Application

SUNTECH Woven Fabric Rolling Machine with Length Counting is suitable for woven fabric, with accurate fabric length counting and fabric edge controlling. It can be supplied to operate from various fabric inlet and outlet options.

Fabric End Stop Sensor

Allow continuous fabric inspection, from one piece of roll to next, no need to feed fabric again.

Full Width Fabric Inspection

60 degree fixed angle inspection screen has been verified to be the best suitable angle for knitted fabric inspection, with the least influence on fabric tension.

Scroll Roller

Three sets of scroll Rollers and one set of air-blowing device to control fabric curled edges.

1. Before inspection, the scroll roller ensure fabric open totally when inspection;

2. After inspection, the scroll roller will open fabric curled edges again to ensure accurate edge-align;

3. Before rewinding, the scroll roller and air-blowing device will once again open fabric and eliminate crease for perfect roll generation.

Digital Counter Meter

The Digital Counter Meter also have pre-set function. If you need 100m, you pre-set the length on the counter meter, when arrives 100m, the machine will stop automatically.

Edge-alignment Sensor

Edge Alignment Photo Sensor will align the fabric edge accurately. When fabric declines, the rewinding station will move left or right for aligning.

Twin Rewinding Roller

Consistent roll output by actively surface rewinding with twin rubber-covered roller. You can also adjust the roll hardness (Loose or Tight) by the hand-wheel.

Horizontal Fabric Rolling Machine

91.8% Response Rate

Knitted Fabric Inspection Machine

91.8% Response Rate

Fabric Batch Inspection Machine

91.8% Response Rate

Shipped by FCL

Shipped by LCL

Q1: Is the fabric inspection machine have length counting?

A1: Yes, "Digital Counter Meter" is installed on the fabric inspection machine which gives Meter and Yard counting. The target length also can be pre-set on the "Digital Counter Meter", When arrives at pre-set length, fabric inspection machine stops automatically.

Q2: How to feed fabric into fabric inspection machine? Easy?

A2: The layout and feeding drawing of Fabric Inspection Machine will be supplied along with the machine.

Q3: Is the fabric inspection machine with top & bottom lights?

A3: Yes. We use LED lights, with long life and energy efficiency than common fluorescent.

Q4: What is the electrical specs? Can I use the fabric inspection machine directly in my country?

A4: The standard voltage is 3 Phase-380V; 50Hz, and we can make it suitable for different countries.

Q5: Is the control panel in English?

A5: Yes, it is in English.

Q6: How long is the warranty? If any problems, how to solve it?

A6: 13 months from the date of shipment. If any quality problems within warranty, SUNTECH will responsible, and we will send new replacements by free. Warranty extension is also available at SUNTECH than other suppliers.

SUNTECH is one of leading designers & manufacture on textile machines for weaving & finishing units. Our scope of products includes Fabric Make-Up Machines, Material Storage, and Handling Equipment. Furthermore, from weaving factory, finishing and dyeing factory to garment factory, we can provide one-stop service for you.

Up to now, we already have 2500 global customers and 6000 installations. Within sales turnover, Asia takes up 48%, Europe 16%, North America 9%, South America 14%, Africa 8%, other countries 5%.

-

Artos Peek material slide (1 large + 2 small) + 4 brass rivet stenter dyeing, coating finishing machine

-

Ingredients Spare Parts Production Line Used Chain Price Sizing Brush Finishing Stenter Textile

-

High-efficiency production of new automatic textile finishing machine fabric double-roller machine

-

CE certification European market welcomes T-shirt automatic folding machine

-

Industrial fabric shrinkers, steam and thermosetting machines

-

Needle bar for vertical Bruckner stenter dyeing and finishing machine

-

Automatic Textile Winding Machine Cloth Winding Machine Roll-to-Roll/Fabric Winding Folding Cutting Machine/Fabric Rewinder

-

Fully automatic fabric winding fabric inspection machine roll to roll fabric cutting printing machine

-

New version of foldimate clothing folding machine automatic clothing folding machine

-

High Quality T Shirt Automatic Folder Machine Clothes Commercial Laundry Folder T Shirt Folding And Packing Machine

Other Products

-

$6000.00 - $10000.00 / set

$6000.00 - $10000.00 / set -

$15000.00 / set

$15000.00 / set -

$3800.00 / set

$3800.00 / set -

$15000.00 / set

$15000.00 / set -

$2000.00 / set

$2000.00 / set