1000 bph chicken slaughtering production line / chicken slaughterhouse equipment

-

Supplier: Zhucheng Xincheng Mingshun Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Mr Louis Qi -

Price: $20000.00 /set -

Min. Order: 1 set

| After-sales Service Provided: | Engineers available to service machinery overseas; | Packaging Detail: | export standard or requirements of clients; |

| Application: | Poultry; | Place of Origin: | Shandong China (Mainland); |

| Supply Ability: | 400 Set/Sets per Month; | Model Number: | MS-LSX; |

| Port: | qingdao port; | production capacity: | 500-8000pcs/hr; |

| Delivery Detail: | Shipped in 30 days after payment; | Payment Terms: | T/T; |

| Name: | chicken slaughtering line; | Brand Name: | XINCHENGMINGSHUN; |

| Dimension(L*W*H): | customized; | Weight: | standard; |

| Certification: | CE ISO; | Condition: | New; |

| Power(W): | standard; | Voltage: | 380V; |

chicken slaughtering line machine for your reference

| 1 | Killing conveyor line | Chicken will be processed on this rail, it is main part for the main slaughter plant Production line. The distance of hangers is 8inch. Stainless steel chain, guide rails, stainless steel hooks, nylon hanger |

| 2 | Electric stunning machine | fiberglass reinforced plastic reliable and stable electrical devices |

| 3 | Scalding machine | This machine is used to scald the carcass of the chicken to remove the feather easily; Thickness of Board: 2mm,Upper cover thickness :1.2mm,Supporting Leg Thickness:2mm. Temperature between 58C°-61C° of the water use blower system and impact pressure system make to produce highly scalder results. |

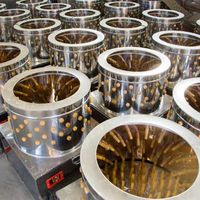

| 4 | A Frame Primary Plucker | This plucker is dedicated device for chickens ,there are 4 main parts: Depilation, regulation section, guide part, spray part. Principal part is stainless steel Shape Size:3350*2350*2350 De-feather Machine consists of four boxes .Each line has 12 plates .Total 6 lines with 72plates. |

| 5 | Automatic cut head machine | this equipment use to auto cut the head on production line Principal part is stainless steel |

| 6 | Automatic cut claw machine | this equipment use to auto cut the feet on production line Principal part is stainless steel this equipment use dedicated accurate chuck location had high quality feet |

| 7 | Unloading claws device | this equipment will be auto take off the feet from production line All body is stainless steel |

| 8 | Drivng device | This machine is to run the whole hang rail including: motor , reducer , brackets and other drive components Power:2.2KW By inverter power, run more smoothly. |

| 9 | Frequency converter |

Frequency controlling box.

Stainless steel box

|

| 10 | Tension device | To control the convey rail length and tight Stainless steel structure |

| 11 | Spiral precooling machine |

This device can replace the precooling line to precooling the chicken carcass

This machine used to low down the temperature of carcass to keep the carcass good-looking and keep fresh in the forward process.

The Thickness of the tank made of 3 stainless steel

Spiral pushing device is melted by 2mm thick stainless steel.

one sets of fan to make bubbles in the water in the tank efficiently so that improve cooling result and clean the carcass too

Buyer Also Need To Prepare cold Water Or A Piece Of Ice MachineBuyer prepare workspace |

If you are interested in our chicken slaughtering machine ,please feel free to contact with us ,there are the question i need to confrim in the below: we will design it as your needs and send you a accurate quotation

1. Have you built the slaughtering line now? Please e-mail the drawing if you have.

We can make the plan based on the space of your workshop.

2. How many square meters of your production room ?

3. Do you need to cut the heads & feet of chickens ?

4. The chickens heads & feet to eat or make the animal feed ?

5. what is the final products do you need ? whole chicken,portion parts/split or others' products ?

6. Voltage/frequency also need to be considered. Please reconfirm your power supply should be 380V/50HZ/3P

7. The biggest slaughter capacity every day?

8. About the weight of chickens slaughter ?

9. Do you need our engineers to supply the professional instruction on site for the equipments installatio

Flow Diagram

Packaging :wrapped in wrapping film before packing which is to avoid moisture on the sea ,this machine is put in wooden/iron crate based on good protection purpose and export standard .

Delivery Detail:15-30 working days

| our services including | Plant desgin |

| Plant Construction | |

| Equipment Production | |

| Equipment installation | |

| Commission | |

| Operation |

Zhucheng XinChengMingShun Machinery Co., Ltd, is a professional production-oriented enterprise, with foreign trading department, specializing in poultry slaughtering equipment, poultry slaughtering lines.

Our company is equipped with advanced computer-aided design (CAD) system, senior and intermediate engineering technicians as the core of design, development and service team to provide customers with preliminary consultation, layout design, installation, debugging and other services. Equipment can be properly used with product of Europe, the United States and other regions. Comparable to similar products in the world market, product performance is in the domestic leading position.

Over the years, the company has been providing long-term equipment and technical services for more than 80% manufacturers in Linyi, China duck industry. It also provides equipment and services to large agricultural and animal husbandry enterprises, such as New Hope Liuhe,CP Group,Doyoo Group,Guiliu Group,Yunken Group, establishs long-term cooperative relations with them. It is the ideal choice of the livestock and poultry slaughtering enterprises at home and abroad.

1.

Q: We don’t have experience on how to build a poultry slaugherhouse. Can we offer full support ?

A: Yes, we can offer a turn key service with the customer information of layout, project plan and other information.

2.

Q: How do you control the quality?

A: We have incoming material inspection, equipment drawing, advance producing machine and final production inspection.

3.

Q:How do you ensure that I received the equipment undamaged?

A:We’ll use standard packaging material and take picture for all equipment to you before the shipment. Please do not openthe package if you find the outer package is damaged. Please take a picture of the damaged package or equipment and send

it to us. We’ll then make a solution plan for it and discuss the replacement or debit.

4

Q: How will you ship your products?

A: Generally we’ll take the sea transportation with our forwarder as term CIF and customer’s forwarder as term FOB.

If a air or express transportation is requested, we can also arrange.

-

New Farm Slaughter Poultry Depilation Machine Moroccan Chicken, New Bird Chicken Duck Depilation Machine Plumer La Volaille

-

Cheap Price Stainless Steel Poultry Slaughter Equipment Set Chicken Cone Killer

-

Slaughterhouse Chicken Slaughter Processing Line Slaughterhouse

-

High Quality Chicken Plucking Machine Poultry Feather Plucking Machine Chicken Washing Machine

-

Chicken Pluckers and Scalders Poultry Depilators Large Chicken Pluckers Selection

-

Professional automatic poultry depilator

-

New fully automatic small slaughterhouse poultry cleaning and slaughtering equipment chicken mobile slaughtering unit mechanical slaughtering line

-

Poultry plucking machine for slaughterhouse processing

-

Rubber Epilator Fingers/New Chicken Machine Cleaning Feather Epilator Used Chicken Epilator for Sale/Chicken Claw Peeling Machine

-

Tolcat Commercial Chicken Depilator Automatic Chicken Depilator Poultry Depilator Fingers For Sale