Slaughterhouse Chicken Slaughter Processing Line Slaughterhouse

-

Supplier: Nanjing Xinbaiyun Equipment Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr jam wang -

Price: $3000.00 /set -

Min. Order: 1 set

Product details

| Packaging Details: | International Shipping Packaging Standard for Customized Slaughterhouse Equipment Chicken Hair Puller Eviscerating Machine | Health status: | new |

| Main selling points: | high productivity | Production capacity: | 500/1000/1500/2000/3000 times/hour |

| Warranty: | 3 years | port: | Nanjing/Shanghai/Ningbo/Tianjin/Shenzhen Seaport |

| Package preview: | Core component warranty: | 3 years | |

| Supply capacity: | 10 poultry slaughtering equipment per month | Origin: | Jiangsu, China |

| Core components: | Bearings, motors, pumps, gears, PLCs, others, pressure vessels, engines, gearboxes | Mechanical test report: | if |

| Marketing Type: | Hot Products of 2021 | After-sales service provided: | On-site service by overseas engineers, free spare parts, on-site installation and commissioning training, on-site maintenance services, video technical support, online support |

| Local service location: | Egypt, Canada, Turkey, United Kingdom, United States, France, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, United Arab Emirates , Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan | Applicable industries: | Construction material stores, manufacturing plants, food and beverage plants, farms, restaurants, construction projects, poultry slaughtering machines |

| Material: | 304 stainless steel | Purpose: | Slaughter machine |

| brand: | New Baiyun | Showroom location: | Egypt, Canada, Turkey, United Kingdom, United States, France, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, United Arab Emirates, Colombia, Algeria , Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Malaysia, Australia |

| weight: | 2200 kg | Certification: | CE/ISO etc. |

| custom made: | Choose to buy product mix according to customer requirements | Name: | Slaughterhouse Chicken Slaughter Processing Line Slaughterhouse |

| Voltage: | 380V | application: | poultry |

| Combination mode: | Various collocations | Video shipment inspection: | if |

| Advantage: | Efficient customization | Suitable: | Chickens, ducks, geese and turkeys |

| Dimensions (L*W*H): | custom made | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, Credit Card |

| pack: | 40" HQ container packing |

Perfect Turkey Project

Bangladesh Torch Program

2018 Halal Complete Set 500BPH Chicken Slaughtering Line Project

Yemen Torch Program

2019 Halal 3000BPH chicken slaughtering line project

Turnkey project in Lithuania

2019 CE certification project 500BPH chicken slaughtering line (air cooling)

processing line | required equipment | ||||||

live poultry conveyor line | crate conveyor washing machine | ||||||

slaughter line | Chain Conveyor Line stunner bleeding groove ironing machine Hair plucking machine cutting machine foot knife Claw unloader | ||||||

visceral line | Chain Conveyor Line visceral tank workbench carcass unloader Scales | ||||||

Pre-cooling line | Precooler corpse collection chute | ||||||

High quality chicken slaughterhouse slaughter production line

poultry slaughtering shackle hook

Used for bloodletting, evisceration, cold storage, etc.

Used for bloodletting, evisceration, cold storage, etc.

It is the main and key component of the production line of large and medium-sized slaughterhouses.

Types of hooks for each part of the slaughtering line.

New design and improved technology can wash the hook very clean Stainless steel structure can guarantee the service life of the machine

usage.

The latest technology from the European Union, combined with our improvements to the machine design, makes it more suitable for the developing country market.

High efficiency and low price, cooperate with the whole slaughtering line, so that customers can easily operate the whole factory.

Types of hooks for each part of the slaughtering line.

New design and improved technology can wash the hook very clean Stainless steel structure can guarantee the service life of the machine

usage.

The latest technology from the European Union, combined with our improvements to the machine design, makes it more suitable for the developing country market.

High efficiency and low price, cooperate with the whole slaughtering line, so that customers can easily operate the whole factory.

Chicken Butcher Shackle Hook

Duck hook

gutting shackle hook

Case washing conveyors are used in poultry processing plants to wash cases. The device uses high-pressure water to wash the dirt inside and outside the box, and the water in the machine circulates automatically to save water. The gasket will be automatically excluded from the equipment through the filter drum to ensure long-term stable and reliable use.

Slaughter and transfer line

The slaughtering line meets the automatic production requirements of poultry slaughtering, scalding and plucking. Strictly comply with commodity inspection and food hygiene standards.

air blowing

The air-blowing scalder is used in the poultry scalding process before plucking. The box-shaped structure is energy-saving. It adopts direct steam heating, automatic control of water temperature and water level, and air flow agitation. It not only has a good scalding effect, but also meets the needs of different types of processing capacity. .

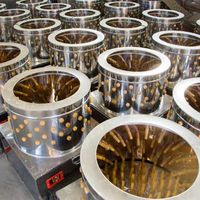

shape picker

The depilator is used for the feathers after plucking, and the corresponding number of working boxes is designed according to the number and length of the working boxes to meet the requirements of different kinds of poultry or handling capacity, and to obtain perfect depilation performance without damaging the beak. The latest waterproof and noise-reducing design of the bearing chamber makes the bearing durable. It has the characteristics of high picking rate, low damage rate, low failure rate, convenient operation and maintenance, easy adjustment and high degree of automation.

Eviscerated Transfer Line

The visceral conveying line is used in the poultry evisceration process. It is made of stainless steel and nylon, controlled by frequency conversion (speed regulation), and strictly complies with commodity inspection and food hygiene standards.

The screw pre-cooler is used for the pre-cooling process after viscera removal. In order to obtain the ideal chilled meat, the chiller adopts high

Pressurized air flow agitation and propeller blade propulsion ensure that the poultry is thoroughly and evenly washed and cooled.

The length varies according to the corresponding processing capacity, and can meet commodity inspection and food hygiene standards.

Pressurized air flow agitation and propeller blade propulsion ensure that the poultry is thoroughly and evenly washed and cooled.

The length varies according to the corresponding processing capacity, and can meet commodity inspection and food hygiene standards.

Portion conveyor line

Portion transfer line for poultry cutting procedures, made of stainless steel and nylon, with

Frequency conversion [speed] control, in strict compliance with commodity inspection and food hygiene standards.

Frequency conversion [speed] control, in strict compliance with commodity inspection and food hygiene standards.

Welcome to contact us to learn more

Combine and match.

VIEW MORE

You may like

-

New Farm Slaughter Poultry Depilation Machine Moroccan Chicken, New Bird Chicken Duck Depilation Machine Plumer La Volaille

-

Cheap Price Stainless Steel Poultry Slaughter Equipment Set Chicken Cone Killer

-

High Quality Chicken Plucking Machine Poultry Feather Plucking Machine Chicken Washing Machine

-

Chicken Pluckers and Scalders Poultry Depilators Large Chicken Pluckers Selection

-

Professional automatic poultry depilator

-

New fully automatic small slaughterhouse poultry cleaning and slaughtering equipment chicken mobile slaughtering unit mechanical slaughtering line

-

Poultry plucking machine for slaughterhouse processing

-

Rubber Epilator Fingers/New Chicken Machine Cleaning Feather Epilator Used Chicken Epilator for Sale/Chicken Claw Peeling Machine

-

Tolcat Commercial Chicken Depilator Automatic Chicken Depilator Poultry Depilator Fingers For Sale

-

Wanhe BZ-600 High Quality Chicken Plucker Machine/ Poultry Plucker/Bird Pluking Machine

Other Products

-

$23880.00 / set

$23880.00 / set

Related Search

chicken slaughter process suppliers

production line poultry chicken slaughtering equipment

breakfast cereal processing line suppliers

new chicken slaughter equipment product

chicken slaughtering

chicken slaughter in machine

rice process line

evapor milk process line suppliers

shandong pet chew food processing line

soybean powder processing line