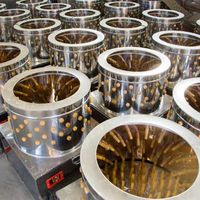

Poultry plucking machine for slaughterhouse processing

-

Supplier: Nanjing Xinbaiyun Equipment Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Selina Shang -

Price: $500.00 /set -

Min. Order: 1 set

Product details

| Applicable industries: | Manufacturing plants, farms, restaurants, households, grocery stores, food and beverage stores | Function: | poultry blanching |

| Suitable for: | slaughterhouse processing plant | capacity: | 300-1000 times/hour |

| Local service location: | Turkey, France, Indonesia, Thailand, Malaysia, South Africa | Key words: | Poultry automatic slaughtering equipment |

| brand: | New Baiyun | Core components: | Bearings, motors, gears, engines |

| Packaging Preview: | application: | poultry | |

| Mechanical test report: | if | Voltage: | 380V |

| Keyword 3: | Poultry slaughterhouse slaughtering machinery | Health status: | new |

| weight: | 350kg | Showroom location: | India, Kenya, Colombia, Romania, Bangladesh, South Africa, Kazakhstan |

| size: | custom size | payment terms: | letter of credit, wire transfer |

| Dimensions (L*W*H): | 2900*900*1720mm | Keyword 2: | Chicken Slaughter Line Poultry |

| Warranty: | 3 years | After-sales service provided: | Free spare parts, on-site installation and commissioning training, on-site maintenance and repair services, video technical support, online support |

| type: | Poultry Processing Machinery | Video external inspection: | if |

| place of origin; place of origin: | Jiangsu, China | Marketing Type: | Hot Products of 2019 |

| Material: | Stainless Steel 304 | Packaging Details: | International shipping and packaging standard or as your request |

| pack: | Standard wooden case | Main selling point: | high productivity |

| Core Components Warranty: | 1 year | port: | Shanghai |

| Supply capacity: | 300 sets per month | Certification: | CE, ISO |

video description

slaughtering process

1000BPH Chicken Processing Equipment

Slaughtering, scalding and cutting are key processes where carcass damage and cross-contamination should be minimized. The height adjustability of our equipment ensures efficient processing and maximum carcass care. Processing and hygiene measures minimize cross-contamination.

*Electrical water bath stun, which helps to stun effectively and minimize possible damage to meat quality.

* Electric muscle stimulation matures faster and improves bleeding.

*Typhoon shower before scalding for cleaner birds during final scalding.

*Multiple immersion ironing tanks for cleaner water.

* Height-adjustable picker for targeted fin adjustments to the picking process and different size ranges.

*Easy to flush the device for optimum hygiene

thing | value |

Applicable industries | Food & Beverage Factory, Farm, Slaughterhouse |

local service location | not any |

Showroom Location | not any |

Health status | new |

application | poultry |

place of origin; place of origin | China |

brand | New Baiyun |

Voltage | 380V |

Size (L*W*H) | custom made |

weight | 200 |

Certification | EU standard |

Warranty | 3 years |

On-site installation, commissioning and training | |

main selling point | High security level |

Marketing Type | New Products 2020 |

Mechanical Test Report | if |

Video checkout | if |

Core Components Warranty | 3 years |

core components | Bearings, motors, gears |

aftersale service provided | Engineers can repair machinery overseas |

Name | Chicken Slaughter Line Machine |

Material | Stainless Steel 304 |

usage | Poultry plucking |

Purpose | slaughterhouse machine |

life | durable |

Suitable for | slaughterhouse |

size | customizable |

Crate Transfer Cleaning

Crate cleaning conveyors are used in poultry processing plants to clean crates. The device is flushed with high pressure water

If the inside and outside of the box is dirty, the water in the machine automatically circulates to save water. The garbage is automatically excluded from the equipment through the filter cartridge to ensure long-term stable and reliable use.

If the inside and outside of the box is dirty, the water in the machine automatically circulates to save water. The garbage is automatically excluded from the equipment through the filter cartridge to ensure long-term stable and reliable use.

high frequency vertigo

Our water stunning machines are designed to best ensure high stunning efficiency and chicken welfare at all line speeds. electricity

Connect between the ground rail and the power rail inside the tub. By achieving an optimal relationship between the currents,

Voltage and resistance, the system immediately causes unconsciousness.

Connect between the ground rail and the power rail inside the tub. By achieving an optimal relationship between the currents,

Voltage and resistance, the system immediately causes unconsciousness.

slaughter

XBY offers height-adjustable butchers to ensure correct cuts and best meet local market preferences; double, single or throat cuts are suitable for halal slaughter.

shackles

XBY offers a variety of slaughter shackles to best suit the size of the bird being handled. Adequate shackle size limits leg compression and ensures proper electrical contact during water stunning.

hot

In our air ironers, birds are suspended in shackles suspended from an overhead conveyor, and they are immersed in hot water. Loosen feathers before picking. Air is used to agitate the water in the scalding tank to create downward turbulence and keep the birds submerged and to facilitate heat transfer to the feather follicles.

pre-cooling

Our stainless steel chillers are efficient, reliable and durable. Spiral design and air agitation system ensure uniform cooling of the birds.The birds were manually re-tethered to the overhead line after water cooling. Further down, water uptake and weight can be measured and the birds sorted for further distribution.

High performance evisceration

Faster line speeds mean higher yields and greater profit opportunities. Today, XBY offers evisceration equipment that can process up to 15,000 chickens per hour without compromising carcass quality and food safety.

* Multiple adjustments to handle different flocks of birds.

*Our machines can efficiently handle poultry sizes of +/- 350 grams in the same machine setup.

*Adjustments can be made during production to optimize uptime.

* Correct adjustment ensures high yields and minimizes fecal contamination.

chopped

The portioning conveyor line is used for the poultry segmentation process, made of stainless steel and nylon, and equipped with frequency conversion control, which strictly conforms to commodity inspection and food hygiene standards.

VIEW MORE

You may like

-

New Farm Slaughter Poultry Depilation Machine Moroccan Chicken, New Bird Chicken Duck Depilation Machine Plumer La Volaille

-

Cheap Price Stainless Steel Poultry Slaughter Equipment Set Chicken Cone Killer

-

Slaughterhouse Chicken Slaughter Processing Line Slaughterhouse

-

High Quality Chicken Plucking Machine Poultry Feather Plucking Machine Chicken Washing Machine

-

Chicken Pluckers and Scalders Poultry Depilators Large Chicken Pluckers Selection

-

Professional automatic poultry depilator

-

New fully automatic small slaughterhouse poultry cleaning and slaughtering equipment chicken mobile slaughtering unit mechanical slaughtering line

-

Rubber Epilator Fingers/New Chicken Machine Cleaning Feather Epilator Used Chicken Epilator for Sale/Chicken Claw Peeling Machine

-

Tolcat Commercial Chicken Depilator Automatic Chicken Depilator Poultry Depilator Fingers For Sale

-

Wanhe BZ-600 High Quality Chicken Plucker Machine/ Poultry Plucker/Bird Pluking Machine