Poly wafer brush Segments road street sweeping brush manufacturing making machine

-

Supplier: Bobo Machine Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Sotu Zhu -

Price: $12000.00 /set -

Min. Order: 1 set

| Showroom Location: | none; | Condition: | New; |

| Applicable Industries: | Manufacturing Plant,Sweeper brush manufacturing machine; | Local Service Location: | none; |

| Dimension(L*W*H): | 1500x650x1600mm; | Weight: | 800kg; |

| Power: | 9kw; | Hydraulic: | 30kn; |

| Effective working area: | 600x600mm; | Material width: | 45-100mm; |

| Voltage: | 380V; | Forming rollers: | 4 sets; |

| Function: | Sweeper brush manufacturing; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Warranty: | one year; | Packaging Detail: | Wooden case for Sweeper brush manufacturing machine; |

| Effective working height: | 500mm; | Automatic Grade: | semi-automatic; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Sweeper brush manufacturing machine; | Port: | Sweeper brush manufacturing machine from Shanghai port; |

| Power(W): | 9kw; | Brand Name: | BOBO; |

| Coiling diameter: | 100-600mm; | Production Capacity: | 800-1000 pcs/h; |

| Package Preview: | ; | Bristle thickness: | 0.7-1.5mm; |

| Place of Origin: | Jiangsu China; | Supply Ability: | 10 Set/Sets per Year; |

| Stroke: | 300mm; | Certification: | ce; |

| Application: | sweeper brush making; |

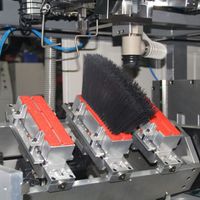

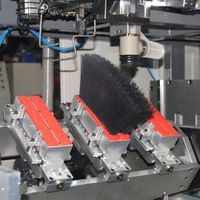

Sweeper Brush Manufacturing Line

This machine line is special equipment of producing different kinds of sweeper brushes, two machines included. One core ring forming machine, can auto forming, rolling and cutting rings at the same time. Another special hydraulic inserting machine for the fast installation of bristle and core rings.

Core ring forming machine

I Advantages

1. The specification ( diameter and length) is adjustable;

2. With production setting function, eight digital counter; can set the product’s quantity, after all finished, the machine will stop automatically;

3. Compact structure, accurate material using;

4. Technology for machining and heating is reasonable;

5. With high precision and intensity parts, long life and wearable;

6. Attractive design, rational construction, low voice, easy and simple to handle;

7. Complete function, with high automation.

II Main technical data:

1 | Suitable material | Q195/Q215 cold roll coil, galvanized sheet, stainless steel etc |

2 | Power | 380V,3P, 4kw or free custom |

3 | Thickness range | 0.7mm-1.5mm |

4 | Diameter range | 100-600mm |

5 | Material width | 45-100mm |

6 | Capacity | 15-20m/min |

7 | Number of main forming rollers | 4sets |

8 | Dimension(mm) | 1800*1500*1200mm |

9 | Weight | 800kg |

Hydraulic bristle inserting machine

I Advantages

1.Casting body ensures long life working.

1.Twin hydraulic system for fast travel reset.

2.Four pillars design keep stable liner travel.

3.Emergency stop and infrared ray for human protection.

II Main technical data:

1 | Effective working area | 600x600mm |

2 | Stroke | 300mm |

3 | Effective working height | 500mm |

4 | Hydraulic | 30kn |

5 | Power | 5kw |

6 | Weight | 1000kg |

| Part | Brand | Remark |

| Mian spinal shaft | hardening and tempering | Local heat treatment |

| Main frame | Welding | Home made |

| Painting | Powder coating | Home made |

| Servo motor | Matsushita | Janpan |

| Oil seal | Yeoshe | Taiwan |

| Electric relay | Schneider | Germany |

| Bearing | NSK | Janpan |

| Contractor | Schneider | Germany |

| Encoder | Omron | Janpan |

| PLC | Delta | Taiwan |

-

3 axis brush making machine/comb brush making machine/comb making machine

-

Brush machine automatic drilling broom brush making machine

-

Brush Machines Shoe Cleaning Handles Varnish Sticks Drilling and Tufting Wooden Broom Making Machines

-

CNC toilet brush tufting making machine for making brush sanding machine

-

Disposable eyelash brush production machine brush making machine for eyelash brush manufacturer

-

Manual Plastic Toilet Brush Making Tufting Machine Wooden Hair Brush Machine Steel Belt Custom Logo

-

CNC 3 Axis 3 Heads 2 Drilling and 1 Brush Sweeper High Speed Production Machine

-

Machine for the production of high-speed brooms

-

5 axis 2 drill 1 tufted high speed beautiful toilet brush making machine can be purchased

-

Industrial Brush Making Machine Automatic Broom Shoe Brush Hair Drilling Making Machine

Other Products

-

$28500.00 / set

$28500.00 / set -

$30000.00 / set

$30000.00 / set -

$800.00 / set

$800.00 / set -

$15000.00 / set

$15000.00 / set -

$10000.00 / set

$10000.00 / set -

$15500.00 / set

$15500.00 / set -

$4680.00 / set

$4680.00 / set -

$800.00 / set

$800.00 / set -

$9900.00 / set

$9900.00 / set -

$1500.00 / set

$1500.00 / set