Electrostatic Powder coating spray gun

-

Supplier: Hangzhou Color Powder Coating Equipment Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Monica Qi -

Price: $900.00 /piece -

Min. Order: 1 piece

| Certification: | CE; | Warranty: | 1 Year; |

| Substrate: | Copper; | type: | intelligent model; |

| Coating: | Powder Coating; | Weight: | 35KGS; |

| Packaging Detail: | WOODEN CASE OR CARTON,Length: 69cm Width: 52cm Height: 56cm Weight: 37 kgs; | Port: | NINGBO/shanghai; |

| Power(W): | 50W; | Condition: | New; |

| Nominal output current (to the gun): | max. 1 A; | Nominal output voltage (to the gun): | max. 12 V; |

| Type: | Coating Spray Gun; | Voltage: | 100-240 VAC; |

| Mains input voltage: | 100-240 VAC; | Used for: | metallic material powder coating; |

| Dimension(L*W*H): | 56*52*69CM; | technical date: | pulse; |

| Supply Ability: | 50 Piece/Pieces per Week as your request; | powder hopper: | 55L stainless steel; |

| function: | surface treatment; | KV: | 0-100KV; |

| Place of Origin: | Zhejiang China (Mainland); | After-sales Service Provided: | Video technical support,Online support; |

| Brand Name: | colo; | Payment Terms: | T/T,Western Union,MoneyGram; |

| powder coating machine: | manual; |

automatic paint spray system , automatic paint coating unit ,aluminum profiles powder painting machine ,Electrostatic powder coating machine ,The CL-191S electrostatic powder manual coating equipment with the

COLO-08 manual powder gun is ideally suited for manual coating of objects in larger series.

The process of the coating is like this :the powder is fluidized in the powder hopper. The injectors transport the powder through the hoses to the guns . The guns spray a powder/air mixture onto the workpieces.

Typical characteristics

- Processing the powder from the fluidized powder hopper

- Quick and simple color change

- Supplied ready for use

- Available with one or two guns (extensible)

CL-191S Electrostatic Powder Manual Coating Equipment,is designed exclusively for electrostatic coating with powder.

0-100 Digital Adjustable KV

Fully Adjustable Amperage

Fully Adjustable Air for Pump on Pressure, Dosage and Nozzle Rinsing Air.

Comes with Full Array of Nozzle Assortment.

Field Tested and Proven to operate in the toughest environments.

Comes with different array of delivery systems:

Because this system is specially balanced for the maximum spray capability with

the Smoothest Finish Possible.

Allows you to create and store your own application programs, optimized for your parts and powder. Each part can be coated always with its ideal settings for experience operator.

Configuration:

A control unit power supply cable

- A air filter

- A air pressure regulator

- A fluidized powder hopper

- A plug-in injector

- An manual powder gun with gun cable, powder

hose, rinsing air hose and standard nozzle set.

- Pneumatic hoses for conveying air (red), supplementary

air (black) and fluidizing air (black)

powder hose

Ground wire

TECHNICAL DATA

| Electrical data | |||

| Mains input voltage | 100-240 VAC | ||

| Operating frequency | 50-60 Hz | ||

| Input power | 50W | ||

| Nominal output voltage (to the gun) | max. 12 V | ||

| Nominal output current (to the gun) | max. 1 A | ||

| IP54 | |||

| Ambient temperature range | 0°C - +40°C (+32°F - +104°F) | ||

| Max. operating temperature | 85°C (+185°F) | ||

| Approvals | CE | ||

| Pneumatical data | |||

| Compressed air connection | 1/4" male quick release | ||

| Max. input pressure | 10 bar / 145 psi | ||

| Min. input pressure (while unit in operation) | 6 bar / 87 psi | ||

| Max. water vapor content of the compressed | air 1.3 g/m³ | ||

| Max. oil vapor content of the compressed air | 0.1 mg/m³ | ||

| Packing Dimensions | |||

| Length | 120CM | ||

| Width | 79CM | ||

| Height | 73CM | ||

| Weight | approx. 55kgs | ||

| Connection Description | |||

| 1.1 Air In | Compressed air connection (6-10 bar / 87-145 PSI) | ||

| 2.1 Power | Mains cable connection (100-240 VAC) | ||

| 2.2 Gun | Gun cable connection | ||

| 1.4 |

| ||

| 1.3 | Pict | ||

| 1.2 |

| ||

| Grounding connection | Pict |

Manual coating equipment Function description

the powder gun through the powder hose . The powder is electrostatically

charged at the nozzle of the gun. In addition, an electrostatic field is

created between the gun nozzle and the grounded object. The charged

powder spray remains adhered to the surface of the object.

The powder is fluidized by air forced through a porous plastic plate from

below. The powder acquires, thereby, fluid-like characteristics.

The conveying air, supplementary air, and rinsing air are set on the control

Unit

The process of the coating is like this: The powder is fluidized in the powder hopper. The injectors transport the powder through the hoses to the guns. The guns spray a powder/air mixture onto the workpieces

related equipments

spray booth

For more details for this spray booth ,pls visit http://www.alibaba.com/product-gs/491056417/Electrostatic_Powder_Coating_booth.html

Curing oven

for more details of this curing oven,pls visit

https://colourspray.en.alibaba.com/product/1132325434-218223918/Electrostatic_aluminum_profiles_powder_paint_powder_coating_oven.html?spm=a2700.8304367.prewdfa4cf.2.6ebc70bbLW4DQE

COLO Powder Coating Systems is a top supplier of powder coating systems and powder coating equipment including manual powder coating equipment, automatic equipment, spray booths,ovens and spare parts

China Powder coating gun, China powder coating machine, China powder coating system, China powder coating equipment, powder coating control unit

We also can supply powder parts replacement of famous powder coating machine , same function,but times lower price!!!

Contact the sales-------inquiry the price of the items you want-----the sales quote the price and make Proforma----

the buyer make payment and note the sales------the sales arrange the delivery

Sales: Monica

Mobile: +86 15325719302

SKYPE:hicolo05

-

Powder Coating Industrial Oven Powder Coating Oven

-

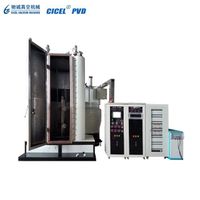

Vacuum coating machine

-

Industrial grade chrome plating machine booth spray paint chrome plating machine

-

Gema Optiflex 2 Vibrating Box Feed Metal Electrostatic Powder Coating Machine Vibrating Powder Coating Machine

-

Stainless steel 10L spray chrome coating machine paint coating nano chrome plating machine

-

Hot Sale Classic Portable Manual Electrostatic Powder Coating Machine (WX-101)

-

High quality automotive hub sputtering vacuum coating machine

-

CE approved industrial powder coating curing oven gas electric stand for sale in China

-

Secondary Vacuum Coating Machine/Vacuum Coating Machine

-

Promote products Mirror spray chrome plating Fine surface spray chrome plating equipment

Other Products

-

$650.00 / set

$650.00 / set