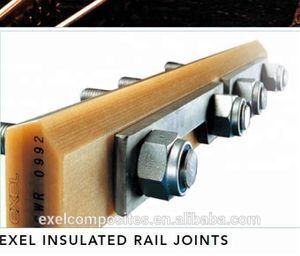

Insulated Rail Joint Systems for Railways and Metros

-

Supplier: Exel Composites (Nanjing) Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr. Simon SHI -

Price: $329.67 / >=100 units -

Min. Order: 100 units

| Usage: | Glass fiber reinforced epoxy matrix; | Name: | IRJ; |

| fatigue resistance: | colour per demands; | Type: | Insulating joints; |

| Standard: | ISO; | Delivery Detail: | 60 days after payment; |

| Supply Ability: | 1000 Unit/Units per Month; | Model Number: | Customized; |

| Port: | Shanghai; | Brand Name: | Exel; |

| Material: | High quality Fiber glass; | Payment Terms: | L/C,T/T,MoneyGram; |

| Packaging Detail: | Per customer demands; | Place of Origin: | Finland; |

| Application: | railway; | Dimensions (L x W x H) (mm): | UIC; |

| Product name: | fish plate; | Keyword: | insulation joint; |

| electrical insulation: | high mechanical strength; |

Insulated Rail Joint System is used as part of the signaling system in several countries and Exel is the market leader in full composite joint systems.

The system consists of glass fibre reinforced joint which is designed according to the track, end plate and fastening system ( bolts).

Exel joints have highest electrical insulation properties, high mechanical strength. Fatigue resistance is far above the fatigue properties of metals.

The design is based on extensive research and the know-how obtained has been proven over years of successful installations of thousands of joints in climate from tropical to arctic.

Fishplate | Spec. value | Tests acc.to |

Construction | Glass fiber reinforced epoxy matrix | N/A |

Fiber Content | ≥65 % by mass | ISO 1172 |

Bending strength (Horizontal) | ≥600 N/mm² | ISO 178, substrates acc. to T-15222-01 |

Bending strength (Vertical) | ≥700 N/mm² | ISO 178, substrates acc. to T-15222-01 |

Tensile strength (Horizontal)

| ≥650 N/mm² | ISO 527, substrates acc. to T-15222-01

|

Toughness Shore D

| ≥90 | ISO 868 |

Elastic bending modulus (Vertical and horizontal) | ≥25 000 N/mm² | ISO 178, substrates acc. to T-15222-01

|

Water absorption | ≤0,02 % | ISO 62 |

Impact strength (Vertical and horizontal) | ≥135 kJ/m² | ISO 179/1 A |

Insulation resistance | ≥1x10^11 | IEC 167 |

Testing procedures are explained in affiliated standards. Manufacturing of substrates

has to be made by using care and proper tools maintaining required orientation.

Angular fault in samples will cause incoherent and inconsistent results that may be

under specification and do not represent the actual properties of the product.

-

Digital rail ultrasonic flaw detector/railway flaw detection device/Rai defect detection

-

2024 Railway maintenance machinery remote control rail tamping machine hydraulic tamping machine hydraulic tamping machine

-

DPG-1 Railway Special Transport Car Lithium Battery Bicycle Single Person Inspection Vehicle

-

Hydraulic gauge adjuster rail gauge adjuster

-

Railway Milling Machine Appropriate Price Railway Rail Grinder FGM Series EU IV Power Time Dimensions Weight

-

Railway clip E2056 Spring clip for railway fastening system

-

Product Supply Railway Steel Spiral Spike Railway Track Accessories

-

2019 Hot Sale YD-22 Railway Equipment Railway Press Machine

-

Factory latest plastic sleepers factory new goods plastic sleepers

-

sale railway track cutting machine track saw railway chainsaw