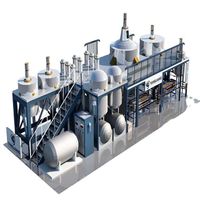

Environmental friendly used engine oil recycling machine / waste oil to base oil distillation plant

-

Supplier: Chongqing Tong Rui Filtration Equipment Manufacturing Co., Ltd. -

Region: Chongqing, China -

Contact: Mr Kunlun Lee -

Price: $30000.00 /set -

Min. Order: 1 set

| environmental protection: | no waste gas; no waste water,no smell; | Local Service Location: | Philippines,Indonesia,Pakistan,Malaysia,Morocco,Sri Lanka,Bangladesh,South Africa,Uzbekistan; |

| Packaging Detail: | Wooden Cases:To be packed in strong wooden cases, suitable for long distance ocean freight transportation as well as changing climate and with good resistance to moisture and shocks.; | Condition: | New; |

| Material: | Stainless steel and Carbon steel; | Certification: | CE ISO; |

| Viscosity(40℃)mm2/s: | 49.57 /26.86; | Noise: | 75dB(A); |

| Single gross weight: | 1000.0 KG; | Applicable Industries: | Oil treatment; |

| Single package size: | XX cm; | size: | provide customise; |

| After-sales Service Provided: | Online support,Engineers available to service machinery overseas; | Place of Origin: | China; |

| Package Preview: | https://sc01.alicdn.com/kf/H605666148d6a4313ad571f002300718dI.png_640x640.png; | Warranty: | 2 years; |

| Dimension(L*W*H): | Custom-made; | product quality: | light yellow; no foul smell; |

| Power(W): | 38-285KW; | certification: | ISO9001:2008,SGS,CE,BV; |

| Brand Name: | TONGRUI; | Flow: | 1Ton per day-50 Ton per day; |

| Selling Units: | Single item; | Voltage: | 220~415V,220V/380V/240V(provide customise); |

| After Warranty Service: | Online support; | Weight: | 7~15 TONS; |

| Showroom Location: | None; | base oil color: | 1.5 or 1; |

Newest technology with high oil output engine oil distillation plant

Contact:Anne Wu Whatsapp:+8615215080377

W Working principle

Waste oil is pumped to mix with the catalyst after being pretreated to remove large impurities, and mixed enough via the special mixing pipe. The mixed waste oil flows into the distillation kettle, meanwhile the waste oil is circulating heated by the heat exchanger. Start the vacuum unit. The components by distillation pass through three-stage cooling systems, then collected into "water receiver, gasoline and diesel receiver, light lube base oil receiver, heavy lube base oil receiver" . The waste gas is firstly handled by the water seal, then handled by our waste gas processor system. The water distilled from waste oil can be used to blend the catalyst, no any pollution water produced. The gasoline and diesel oil distilled from waste oil can be used as fuel blended with oil residue. Therefore, our equipment has no any secondary pollution to the environment.

Advantage:

Our Vacuum and Oil Distillation plant is the newest technology with high oil output engine oil distillation plant, the physical separation of components of lubricating oil by boiling range. Depending on the type of distillation, the boiling ranges can produce gases and gasoline at the lower boiling points with heavy lubricating oils being distilled at higher boiling points. Distillation is the core process for a facility capable of producing re-refined base-oils to virgin base-oil quality. And the machine is easy to operate,only 1-2 workers is enough to control the machine.

Features:

1. Easy to operate, low operation cost

2. Environmentally friendly, without secondary pollution.

3. The machine can recycle gasoline oil, diesel oil, engine oil, rubber oil and other lubricant oil to clean oil.

4. High quality refined oil, no any discoloration caused by oxidation, no any bad smelling.

5. Low cost contain:

1) only need the catalyst chemical, the cost is less thanUS$30 to refine one ton waste oil.

2) Heat consumption: 105kcal per ton waste oil

3) Power consumption: 40Kwh to recycle 1 ton waste oil

6. High degree of automation.

Main Components:

1. Catalyst system: Catalyst Reactor, blender;

2. Chemistry treatment system: Chemistry reactor, blender, oil pump

3. Heating distilling system: distilling tower, distilling kettle, heater, circle pump;

4. Cooling system: refrigerating machine, water pump, water tank, cooler I, cooler II, Condenser;

5. Vacuum system: Vacuum water receiver, vacuum pump, vacuum cooler

6. Degasification system: vacuum exhauster, exhaust fan, degasification plant, water pump, radiator, deodorizer.

7. Oil storage system: distilling storage tank

8. Control system: all kinds of gauge( vacuum gauge, pressure gauge etc.) and electricity controller tank.

Recovery Rate:

Component | Percentage(%) |

water | 1.5% |

Gasoline/diesel oil | 7% |

Light Lubrication oil | 42% |

Heavy Lubrication oil | 43% |

Residue | 6.5% |

Total | 100%

|

Treated Oil Analysis (take the waste diesel engine oil for example)

Item | Heavy Lube oil | Light Lube Oil |

Appearance | lucidity | lucidity |

Color ≤ | 1.5 | 1 |

Viscosity (40°C)mm2/s | 49.57 | 26.86 |

Viscosity Index ≥ | 96 | 95 |

Anti-oxidation 150°C,min ≥ | 180 | 180 |

Deemulsification,54°C | 5min | 5min |

Flash Point(Open)°C ≥ | 228 | 224 |

Pour Point °C ≤ | -12 | -16 |

neutralization value (mgKOH/g) ≤ | 0.02 | 0.02 |

More Products and Configuration

Here are our main categories below:

ZJB Single stage vacuum transformer oil purifier

ZJA Double stage vacuum transformer/insulating oil purifier

ZJA-M Mobile Trailer type transformer oil purifier

IIJ-II Insulating/transformer oil dielectric strength tester

ZJD Lubricant/hydraulic/turbine oil purifier

ZJF Cooking oil purifier

NRY Waste engine oil regeneration system

ZJD Coalescence and separating oil purifier

ZJR Phosphate ester fire-resistant oil purifier

ZJD-K Plate pressure oil purifier, Portable oil purifier

AD Air dryer for drying electric equipments

ZJD-S Oil water separator

DIR Waste engine oil distillation plant

DDR Diesel oil distillation plant

NKEE-36 Oil moisture sensor

BDV Oil tester

Contact Anna Wu for more details. whatsapp/wechat/mobile:008615215080377

-

Yangjiang waste oil refining equipment recycling waste motorcycle or automobile oil waste oil regeneration machine

-

Recycling waste oil into diesel oil refinery is highly profitable and low cost

-

China Made Heavy Fuel Oil Distillation Mini Refinery

-

Standard Diesel and Gasoline or Crude Distillation Units in U.S. Crude Oil Refinery

-

2023 NEW Oil filter machine Oil filter equipment manufacturing

-

New continuous oil filter oil recovery machine

-

Factory supply portable oil purifier hydraulic oil filter cart oil purifier unit

-

500kg/day small edible oil refiner crude oil refiner HJ-JLYJ200

-

Distillation Unit Price of Small Crude Oil Refinery

-

New energy TYR waste oil to diesel plant edible oil recovery machine oil filter machine

Other Products

-

$40000.00 / set

$40000.00 / set -

$4500.00 / set

$4500.00 / set -

$30000.00 / set

$30000.00 / set -

$4500.00 / set

$4500.00 / set -

$5000.00 / set

$5000.00 / set -

$30000.00 / set

$30000.00 / set -

$40000.00 / set

$40000.00 / set