coal rotary drum dryer, lignite coal rotary vaccum dryer, brown coal steam tube rotary dryer

-

Supplier: Zhengzhou Hongji Mining Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Selen Yu -

Price: $3500.00 /set -

Min. Order: 1 set

| Port: | Shanghai, Tianjin, Qingdao, as your request; | Power(W): | 3-175kw; |

| Type: | Drum Drying Equipment; | Warranty: | 2 years; |

| Weight: | 2.9-104.9t; | Dimension(L*W*H): | Varied; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Condition: | New; |

| Application: | ore , clinker, stone ,sand , limestone; | Installation: | Under Technician's Guidance; |

| Certification: | CE ISO; | Fuel type: | coal ,gas ,oil; |

| Place of Origin: | Henan China; | Applicable Industries: | Building Material Shops,Construction works ,Energy & Mining,wet dry material; |

| Price: | Negotation; | Service: | free after sale service; |

| Spare parts: | no matter when; | Voltage: | 220v/380v; |

| Raw Material: | Multiple Material; | Application: | Medicine Processing,Chemicals Processing,Plastics Processing,Food Processing,wet dry material; |

| Brand Name: | Hongji; | Key Selling Points: | Energy saving; |

| Product name: | lignite coal rotary vaccum dryer, brown coal steam tube rotary dryer; | Package: | wooden box and steel wire; |

| After-sales Service Provided: | Online support,Video technical support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service; | Feature: | high quality with competitive price; |

| Packaging Detail: | Export Standard Package or as per Customer's request; | Supply Ability: | 30 Set/Sets per Month lignite coal rotary vaccum dryer, brown coal steam tube rotary d; |

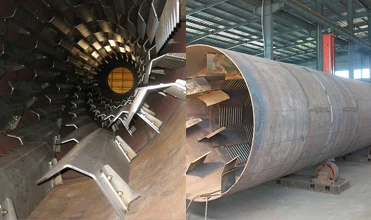

coal rotary drum dryer, lignite coal rotary vaccum dryer, brown coal steam tube rotary dryer

| INTRUDUCTION FOR ROTARY DRYER | |

| Brief Introduction | Rotary dryer is widely used to dry materials in industries like cement, mine, construction, chemical, food, compound fertilizer, etc. Thermocouples are installed in feeding and discharging units to control temperature. Temperature change of the dryer also can be indicated by the thermometer, which is convenient for temperature control inside the dryer ( it is usually 250-350℃). |

Applications | Powder & particle: Sands, limestone, stones, clay, mineral filter cake, coal, iron sulphate, filter cakes, fly ash, gypsum etc. Damp and sticky material: Coal slime, sewage sludge, bentonite, Kaolin etc. Corrosive material: Distillers ‘grains, Fertilizer, animal dung, slag etc. Biomass material: Sawdust, wood chips etc. |

Features | 1.International standard with ISO, CE certificate. |

2.Simple system, safe and easy operation. | |

3.Flexibility in fuels used (NG, Oil, Coal ect.). | |

4.Year of experience with all types of dryers. | |

5.Capable of installation anywhere in world. | |

6.In house engineering for custom fit applications. | |

7.Proven design. | |

| Point 1-Steel Plate Selection

Chemical analysis was carried out on the material inspection, according to the requirements of GB700-2006, dryer drum thickness < = 20 mm we use Q245 - A, > 20 mm we use Q245 - B; According to the GB/T 2970-2004 class ii, the range of 60 mm weld edge every board before cutting for ultrasonic flaw detection. | |

Point 2-Dryer Drum WeldingThe dryer cylinder section for toroidal welding, longitudinal along the entire circumference of not more than two weld article number, and shell welds shall be full, the minimum is not lower than the parent metal surface, the top should not be higher than 3 mm, feed plate weld should be smooth.Weld edge bite depth should not be greater than 0.5 mm, continuous length should not be greater than 100 mm, should not exceed the total length of each weld bite edge which 10% of the weld length. | ||

Point 3-nspectionExamination all the parts according to the drawing after processing completion. Spraying primer, rust preventing paint, and heat resistance paint. |

Rotary Dryer Structure

Working Site of Rotary Dryer

Technical Parameters

Certifications

Packing & Delivery

Our Successful Case

Q: For providing you the suitable quotation we need to know the following information:

A: 1.What is the raw material for the production line?

2. What is the capacity per hour you required?

3. What is the maximum input size of the raw material?

4. What is the output size and application for the final product? Once we get your answers, I can provide you the best quotation immediately.

Remarks: The price will depend on different models. Reply message you will get 5% discount price.

Q: What about Warranty of the products?

A: Hongji Machinery grants our customers a twelve-month-period warranty from the date of delivery for machines exported from us. During the warranty period, in case any defect of material or workmanship occurred with spare parts in normal operation, we will at our discretion replace or repair the defective parts freely.

Q: The reason you choose Hongji Machinery:

A: 1. Professional manufacturer of supplying mining crushing equipment, construction equipment, Ore beneficiation equipment and mining dryers.

2. Experienced and professional R&D team and manufacturing team;

3. Professional sales team consisted of dedicated, dynamic and innovative people with international version.

4. Professional logistics service ensuring safety and timely delivery of products all over the world through ocean, airline, road and railway.

-

Best quality 10kg 15kg freeze dryer food drying freeze dryer price household oil-free vacuum pump usa ready stock

-

Vacuum freeze dryer price

-

Household 6kg 8kg fruit food mini vacuum drying household freeze dryer freeze dryer with vacuum pump machine US spot

-

Mini Vacuum Freeze Dryer For Sale

-

Digital Display Multifunctional Combination 8 in 1 Heat Press Machine Sublimation Printing T-shirt Cup Tray Hat Printing

-

Vacuum drying machine, milk powder for vacuum drying

-

Factory price mini industrial vacuum food freeze dryer price

-

220V / 110V Household Professional Food Dehydrator Fruit Dryer

-

Stainless Steel Vacuum Chamber Vacuum Degassing Chamber Glass Cover Silicone for Evacuating and Protecting Food

-

2019 China Laboratory Industrial Small Freeze Dryer Price For Sale

Other Products

-

$3000.00 / set

$3000.00 / set -

$50000.00 / set

$50000.00 / set -

$999.00 / set

$999.00 / set -

$15000.00 / set

$15000.00 / set -

$50000.00 / set

$50000.00 / set -

$3200.00 / set

$3200.00 / set -

$200.00 / set

$200.00 / set -

$8000.00 / set

$8000.00 / set -

$15000.00 / set

$15000.00 / set