Special Anchor and Frame Type Low Speed Impeller for Agitator Mixers heat transfer of middle, high viscosity medium

-

Supplier: Zhejiang Greatwall Mixers Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Monica Ke -

Price: $20.00 /set -

Min. Order: 1 set

| Applicable Industries: | Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Food Shop,Printing Shops,Energy & Mining; | Spare Parts Type: | custom impeller; |

| After-sales Service Provided: | Free spare parts,Video technical support,Field maintenance and repair service,Online support,Field installation, commissioning and training; | Packaging Detail: | Exporting Standard Packing--Wooden Case.; |

| Local Service Location: | Indonesia,India; | Warranty: | 1 YEAR; |

| Payment Terms: | T/T; | Supply Ability: | 1 Set/Sets per Week; |

| Condition: | New; | Key Selling Points: | widen the mixing range; |

| polish: | Ra 0.2~3.2; | material: | stainless steel or carbon steel; |

| Port: | China Port; | Place of Origin: | Zhejiang China; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Showroom Location: | None; |

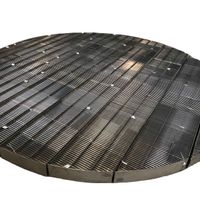

MKS- Special Anchor and Frame Type Impeller

- Improved heat transfer for fluid viscosities from 10,000 to 100,000 centipoises

- improve heat transfer with optional wall scrapers.

- more economical than other laminer flow impellers.

You can benefit from MKS-Anchor and Frame Type Impeller following features:

Special anchor and frame type impeller (metal impeller, stainless steel impeller)

These low speed impellers are used in processes of mixing and heat transfer of middle, high viscosity medium. The working conditions are: μ<50000cP, n=1~100rpm. Type MKS impeller produces strong shearing force at low rotation speed. It can avoid solute depositing and attaching. The bottom of the impeller agrees with the elliptic tank. Type MDS impeller combines functions of helical ribbon type and frame type. Type FKS ans FSS impellers have simple structure and can easily be manufactured. Their performance is similar to frame impellers. They are suitable for mixing and dissolving middle viscosity medium. Type BKS is a simple low speed impeller. The holes inthe frame can be adjusted.

Dimensions of Special Impeller

Dj | d | d2 | n | H | B | δ | d1 | L | Weight (kg) | ||||

MKS | MDS | FKS | FSS | BKS | |||||||||

500 | 50 | 85 | 85 | 500 | 50 | 8 | M8 | 30 | 11.24 | 16.81 | 15.29 | 14.25 | 26.6 |

560 | 55 | 90 | 90 | 560 | 56 | 8 | M8 | 30 | 13.52 | 19.90 | 18.31 | 16.08 | 32.7 |

630 | 60 | 100 | 100 | 630 | 63 | 10 | M10 | 40 | 20.36 | 28.80 | 27.43 | 25.79 | 46.9 |

710 | 65 | 105 | 105 | 710 | 71 | 10 | M10 | 40 | 25.05 | 37.07 | 33.62 | 29.66 | 57.3 |

......

2500 | 150 | 220 | 220 | 2500 | 250 | 18 | M20 | 100 | 423.5 | 579.8 | 547.0 | 346.7 | 942 |

2800 | 160 | 240 | 240 | 2800 | 270 | 18 | M20 | 100 | 537.8 | 746.4 | 696.0 | 412.4 | 1191 |

3150 | 180 | 260 | 250 | 3150 | 300 | 20 | M20 | 120 | 726.5 | 983.7 | 934.1 | 525.5 | 1610 |

3550 | 200 | 280 | 260 | 3550 | 330 | 20 | M20 | 140 | 904.1 | 1267 | 1158 | 661.1 | 1950 |

Remarks: The inner hole of impeller can be made according to the request of customers, and wheel hup height is the same as the inner hole.

INSTALLATION

GREATWALL provide expert help on installation, whether your application requires a single agitator or a group of agitators for an entire plant.Our engineer can quickly and efficiently supervise the installation.

|

MAINTENANCE

The agitator user manuals will provide detailed maintenance specification. Please read them carefully and comply with each item. GREATWALL will distribute maintenance communications periodically, which will thoroughly review procedure recommendations for installation, operation, and maintenance of the agitators. |

SPARE PARTS

|

Our spares program includes individual recommendations and review of your spare parts stock based on your equipment and process. Our large inventory supports your stock, and provides quick fulfillment of maintenance and repair needs ,including standard replacement items such as seals, bearings, and lots of internal subassembles.

|

FAQ

1. Why your Mixers similar with other supplier?

We are a listed enterprise. We are the manufacturer and had been in this industry for more than 30 years, with more than 18 years export experience. We design machines by ourselves with advanced technology. Appearance just a part of machine, Service and quality is more important than it.

2. I'm new in our industry, but I'm planning to setup a factory, What can I do?

With our latest technology and an examination of your specific requirements, we can recommend the optimum equipment for your application. We have built one of the most advanced mixing laboratory in the world which includes high speed video imaging, Particle Image Velocimetry(PIV),Brookfield viscometer, and the latest CFD analysis software(Fluent),give us powerful tools to accurately predict mixing performance, So you can bring your fluid to our lab if you are not sure the mixing performance or develop a new product. We could send our engineer to your factory to supply installation guide and train your worker of Operation and maintenance. Any more requests. Just let us know.

We supply services:Design-Manufacturing- Installation Guide - Training- Maintenance- Technical Support.

3.What kind of mixers can you supply to customer?

We could offer a wide variety of applications as bellows:

(1) Environmental Protection

Flue Gas Desulfurization (FGD), pollution nuisance treating, green industry

(2) Pharmaceutical

Biological technology, fermentation, medicine

(3) Petrochemical

Rubber, resin, polyester, lastics, chemical fiber and oil combinations

(4) Fine Chemical

Chemical reagents, fertilizer, spice, industrial drug, soap making, agricultural chemicals, organic and inorganic chemicals

(5) Mineral Processing

Nonferrous metal, rate metal, rare-earth element, gypsum

(6) Food and Beverage

Biochemical food, sugar, fermentation, cooking oil,beverage

(7) Water Treatment

Water treating, purified water treating, industrial water and sewage treating

(8) Coating and Dyestuff

Ink making, paint, coating, paper manufacture

(9) Special Machine

Macadam treatment, cement treatment, bituminous treatment, heat-barrier material, cooling fan

Packaging:

Packing by wooden case usually, we also do other packaging as per customer's requirement.

Shipping:

· European Countries:22-28 days

· United States: East -13-16 days, West--21-28 days

· Brazil: 30-40 days

· Russia:36 days

· Asia Countries: 3-5days

-

Marine Scrubber Vane Demister Droplet Separator Demister

-

1000mm stainless steel elliptical hemispherical conical quasi-spherical head pressure vessel cans

-

China new design sealed top loading arm and fmc loading arm supplier

-

Floor-mounted loading control electronic cabinet with railcar top loading arms for tank farms

-

Manufacturers supply the liquid distributor through the stainless steel liquid distributor

-

Ammonia distillation unit sieve plate stainless steel perforated sieve plate

-

Protect Mail Material Inflatable Airbag Bubble Column Packaging For Cosmetics

-

2022 High-efficiency column internals trough liquid distributor

-

Rail tank car, road tank car upper and lower loading arm

-

York Mesh 431, 421, 326 Supply, Wire Mesh 2205 Mist Eliminator Factory Supplier