HTW200JD Ningbo HAITAI Medical disposable syringe injection Automatic molding making machine

-

Supplier: Ningbo Haitai Industry And Trade Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Peijune Wang -

Price: $25000.00 /set -

Min. Order: 1 set

| screw speed: | 155 rpm; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,DDU; |

| Port: | NINGBO; | Screw L/d ratio: | 23.3-21-19.1; |

| Injection Screw diameter: | 45-50-55mm; | Model Number: | HTW200JD; |

| Weight (KG): | 7000; | Distance between Tie Bars: | 530*530 mm; |

| Ejector Stroke(mm): | 140 mm; | Plastic Processed: | PP,ABS,PPR,HDPE,EPS,PA,PE,HDPE/PP,ABS/PP,PE/PP; |

| Injection Rate (g/s): | 154 g/s; | Injection Weight (g): | 383 g; |

| injection pressure: | 207-168-139 mpa; | Clamping Force (kN): | 2000 kN; |

| Injection Rate: | 124-154-186 g/s; | Power (kW): | 13.6 kW; |

| Brand Name: | HAITAI; | Distance between Tie Bars(Width)(mm): | 530 mm; |

| Automatic: | Yes; | Plastic Type: | Thermoplastic; |

| Ejector Force(kN): | 70 kN; | Local Service Location: | Egypt,Indonesia,Mexico,Russia,Spain,Bangladesh,South Africa; |

| Key Selling Points: | Easy to Operate; | Condition: | New; |

| Supply Ability: | 2400 Set/Sets per Year Injection Molding Machines; | Style: | Horizontal; |

| Opening Stroke: | 475 MM; | Packaging Detail: | Servo System Plastic Injeciton machine packed in WOODEN PALLET.; |

| Screw L/D Ratio: | 22; | After Warranty Service: | Video technical support,Online support,Spare parts; |

| Distance between Tie Bars(Height)(mm): | 530 mm; | Certification: | CE, TUV; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Machine Type: | Hydraulic; |

| Showroom Location: | Egypt,Mexico,Bangladesh; | Screw diameter (mm): | 50 mm; |

| Theoretical Shot Volume(cm³): | 420 cm³; | After-sales Service Provided: | Video technical support,Free spare parts,Field installation, commissioning and training,Online support; |

| Injection Weight: | 310-383-466 gm; | Type: | Injection molding; |

| Applicable Industries: | Building Material Shops,Manufacturing Plant,Food & Beverage Factory,Printing Shops; | Warranty: | 1 year; |

| Open Stroke(mm): | 475 mm; | Place of Origin: | Zhejiang China; |

HTW200JD Ningbo HAITAI Medical disposable syringe injection Automatic molding making machine

1. SPECIFICATIONS

Advantage: Strong Technical design ability, Stable quality, and large production capability, Famous brand.

HTW/JD servo energy saving Injection Molding Machine, equipped with high performance servo motor controlling system, the machine's output power can vary in accordance with the loading changes,which reduce

energy consumption and noise. The motor rotates at lower speed in holding pressure stage, an doesn't

work in cooling time.

The Performance of servo energy-saving molding machine:

- Servo motor can optimize the match of energy demand and realize automatic adjustments.

- It can improve injection precision

- It can greatly save power and water, resulting in environment-protection and energy-saving

- Quick response and low noise.

2. TECHNICAL PARAMETERS

SPECIFICATION | HTW200/JD | |||

A | B | C | ||

INJECTION UNIT | ||||

| Screw diameter | mm | 45 | 50 | 55 |

| Screw L/D ratio | L/D | 23.3 | 21 | 19.1 |

| Shot volume(theoretical) | cm3 | 340 | 420 | 510 |

| Injiection weight(ps) | g | 310 | 383 | 466 |

| Injection rate | g/s | 124 | 154 | 186 |

| Injection pressure | Mpa | 207 | 168 | 139 |

| Screw pressure | rpm | 155 | ||

CLAMPING UNIT | ||||

| Clamping force | kN | 2000 | ||

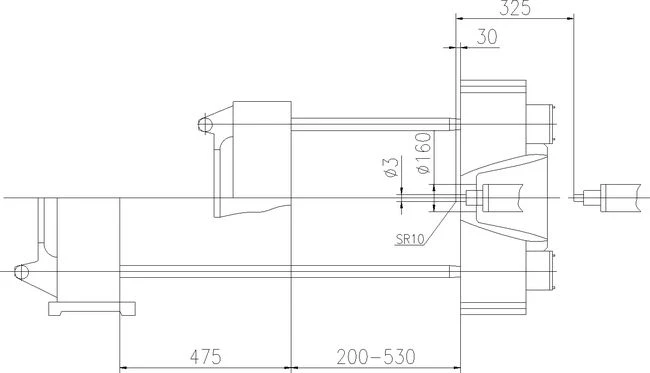

| Open stroke | mm | 475 | ||

| Space between tie bars(W×H) | mm | 530×530 | ||

| Max.Mold height | mm | 530 | ||

| Min.Mold height | mm | 200 | ||

| Ejector stroke | mm | 140 | ||

| Ejector force | kN | 70 | ||

OTHERS | ||||

| Max.Pump pressure | MPa | 16 | ||

| Pump motor power | kW | 18.5 | ||

| Heating power | kW | 13.6 | ||

| Machine dimension(L×W×H) | m | 5.22×1.57×2.21 | ||

| Oiltank cubage | L | 300 | ||

| Machine weight | t | 7 | ||

| PLATEN DIMENSIONS |  |

| MOULD SPACE DIMENSOINS |  |

3.PRODUCTION DESCRITION

CONTROL SYSTEM

All-digital control system uses dedicated controller, multiple CPU processing division,

a multi-functional automatic fault detection, alarm system, certificates 99 mold of

processing procedures, with remote control interface. System is of high stability and

responsiveness. System uses color LCD, man made interface for easy operation and

with a number of peripheral interfaces.

FEATURES

- A variety of text can be switched.

- Manual, semi-automatic and fully automatic mode.

- To provide EUROMAP robot interface.

- Automatic movement monitoring with alarm and fault diagnosis.

- Function of slope setting can set the start and stop of movements, so as ensure the smooth movement

HYDRAULIC SYSTEM

Advanced hydraulic system design, through proportional control of pressure, flow achieves rapid multi-level

pressure, speed switching, the system configuration is reasonable, stable and reliable. The noise is less

than 75 dB. The medium and large machine adopts a two way cartridge inserted valve system to improve

the system of flow and speed of response, and makes the whole machine reach the best performance.

CLAMPING SYSTEM

- Security doors fitted with hydraulic, mechanical and electrical interlocking triple safety device. When the safety door is open, the machine cannot clamp.

- Low pressure mold protection device to prevent damage to platen.

- Plywood, frame, the bridge, and the template attached structure, the finite element analysis.

- Hydraulic ejector, adjustable stroke, and top speed of ejector in and out, for multiple actions.

- Flexible tie bars nut eliminates fatigue fracture; assure the working life of tie bars

- Automatic adjustment. The replacement of different mold, the parameters set by clamping force to achieve the automatic adjustment.

- High-precision electronic detection device, multi-stage control of opening stoke, speed and location, location accuracy.

INJECTION SYSTEM

2005, diversified screw optimal design municipal science and technology research projects focus on key issues is completed, and is now designed professionally and

production for a whole variety of raw material. the diversity of the screw is for your option.

FEATURES

- There are three or four screws and barrels with optimal design, respectively, nitride, hard plating, dual-metal, which is suitable for different processes of a variety of plastics. and the choice of product.

- Two-guided guided bar supports, double-balanced rapid injection.

- The high-torque hydraulic motors offer a stable plasticizing capacity, highprecision electronic device position detection enable accurate measurement.

- Multi-injection speed and pressure and multi-level holding pressure settings, switch from the injection time, location, pressure control to ensure the quality of molding.

- Multi-level back-pressure of pre-plastic and pre-speed are computer-controlled, anti- drooling and automated auto purge.

- Expected to prevent cold-start function to ensure that the screw, Liao Tong will not be harmed. Stability of the injection unit.

-

Second-hand Haitian injection molding machine Standard injection molding machine Second-hand 330-ton servo motor

-

Highshine 250 Ton Servo Injection Molding Machine Trash Can Making Machine Maquina Inyectora De Plastico Precio

-

Fully automatic new horizontal PPR electric EPS polystyrene chair PC PVC PP PET preform plastic injection molding machine

-

Plastic Paint Bucket Container Box Making Machine Plastic Turnover Box Injection Molding Machine Plastic Fruit Basket Molding Machine

-

Low Price Used Haitian 120 Tons SA1200 Injection Molding Machine

-

metal injection molding china powder metal parts Precision metal works MIM parts factory medical instrument Door Lock Cylinder

-

Used high quality Japan NISSEI 7 tons small all electric injection molding machine

-

2021 Hot Sale Desktop Plastic Injection Molding Machine Small Injection Molding Machine

-

Wholesale plastic manual benchtop mini injection molding machine for making plastic parts

-

Injection Molding Machine for Disposable Infusion Set Infusion Set Production Line

Other Products

-

$300.00 / set

$300.00 / set -

$400.00 / set

$400.00 / set -

$15500.00 / set

$15500.00 / set -

$21900.00 / set

$21900.00 / set -

$23500.00 / set

$23500.00 / set