High quality PP Non Woven Fabric Fully Automatic Hot Foil Stamping Machine

-

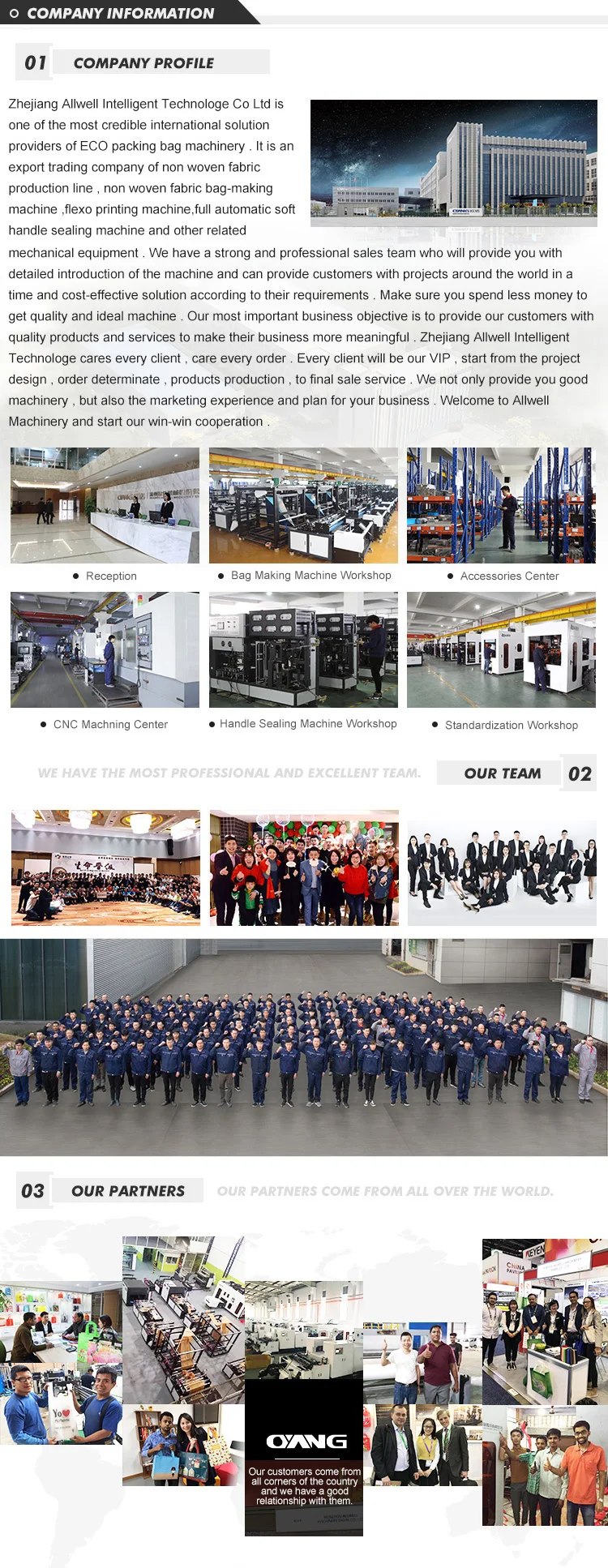

Supplier: Zhejiang Allwell Intelligent Technology Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Sara Yang -

Price: $55000.00 /set -

Min. Order: 1 set

| Warranty: | 1 year; | Gross Power: | 24Kw; |

| Dimensions(L*W*H): | 5200x2000x1900mm; | Feeding thickness range: | 80-150GSM; |

| Applicable Industries: | Manufacturing Plant,Printing Shops,Advertising Company; | Supply Ability: | 30 Set/Sets per Month; |

| Speed: | 3200 times/h; | Port: | NingBo; |

| Foil feeding shafts: | 1 Groups; | Feeding Width: | 600-1200 MM; |

| Local Service Location: | None; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Usage: | Paper Printer,Cloths Printer; | Key Selling Points: | Automatic; |

| Color & Page: | Multicolor; | Condition: | New; |

| Max. working pressure: | 120T; | Brand Name: | ALLWELL; |

| Place of Origin: | Zhejiang China; | Certification: | CE; |

| Type: | Other; | Weight: | 6000KG; |

| Max diameter of feeding rolle: | 800 MM; | After-sales Service Provided: | Online support; |

| Automatic Grade: | Automatic; | Showroom Location: | None; |

| Max.sheet size: | 1280*600 MM; | Payment Terms: | L/C,D/A,D/P,T/T; |

| After Warranty Service: | Video technical support,Online support,Spare parts; |

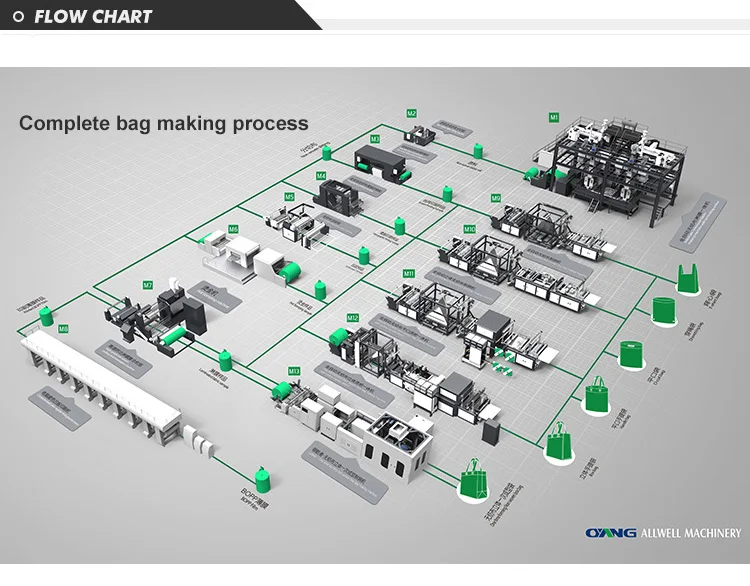

As a new generation of products at home and abroad, is suitable for PP non woven fabric, regeneration non woven fabric, lamination non woven fabric etc.

The main components selection of imported PLC, the main machine adopts imported frequency converter, to ensure the stability of the machine, positioning with HD color mark sensor, convenient operation.

Q1. How long will your engineer reach our factory?

Our After-sales Specialist would contact with you, confirm the final scheduling according to your reasonable request.

Q2. How many days will you finish installing?

We will finish installation and training within 7-10 days.

Q3. What should we charge for your engineer?

You should charge for the cost of our engineer's visa, air tickets,SIM card, hotel, food, and also their salary 80USD one day per person.

Q4. How long is your machine's warranty period?

All our machine have one year guarantee, starting from finished installation.

Q5. How could we do after one year warranty period?

We also can do service for you, but you need pay salary for my technician 80USD/day.

Q6. How could we do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

Q7. Does your engineer understand English?

Our engineers understand a little English. All of our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

Q8. How do we solve the machine problem after your engineer leaving?

Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our after sales specialist at any time.weour after-sales department with 30 engineers.Our engineers will take a solution video according your description.

Q9. How many workers do we need running those machines?

Except two for bag making machine, flexo printing machine, slitting machine, ultrasonic sewing machine, hydraulic punching machine only need one person for each.

-

NORITSU QSS 3202SD digital mini laboratory NORITSU QSS

-

High-quality single-color large sliver printing machine using German FESTO rollers

-

Craft Express Hot Sale Print Head Transfer Machine A3 A4 Thermal PET Film DTF Printer T-shirt Garment Inkjet Printer

-

CF620C A2 Automatic Small Offset Printing Machine

-

HD-68D PVC Card Embossing Machine Card Embossing Machine PVC Card Printer

-

Fully Refurbished Fuji Frontier 500 550 Digital Photofinisher

-

536 Automatic Paper Numbering Puncher

-

CF47II-NP monochrome offset printing machine

-

Noritsu QSS 3202 Digital Printing Machine 3201 3202 3203 Laser Photo Printer

-

Fuji frontier 340 digital minilab for sale, used high quality digital printer FUJI 340

Other Products

-

$38000.00 / set

$38000.00 / set -

$12000.00 / set

$12000.00 / set -

$6000.00 / set

$6000.00 / set -

$18000.00 / set

$18000.00 / set -

$18000.00 / set

$18000.00 / set -

$10000.00 / set

$10000.00 / set -

$6500.00 / set

$6500.00 / set -

$25000.00 / set

$25000.00 / set -

Leather Patch Nonwoven Aluminium Foil Fabric Textile Embossing Machine, Embossing Machine for Fabric$25000.00 / set

Leather Patch Nonwoven Aluminium Foil Fabric Textile Embossing Machine, Embossing Machine for Fabric$25000.00 / set -

$12000.00 / set

$12000.00 / set