Newest Green Energy Plastic Pyrolysis To Oil Machine

-

Supplier: Zhengzhou Yuxi Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr John Cai -

Price: $29850.00 /set -

Min. Order: 1 set

| Packaging Detail: | Standard exporting packing for long distance sea transportation for Plastic pyrolysis to oil machine; | Supply Ability: | 80 Set/Sets per Month Plastic pyrolysis to oil machine; |

| Type: | waste oil refine; | Name: | Newest Green Energy Plastic Pyrolysis To Oil Machine; |

| Material: | Scrap tire&Waste plastics&Waste rubber; | Local Service Location: | United States,Brazil,Indonesia,India,Mexico,Sri Lanka; |

| Operating Pressure: | Negative Pressure Plastic pyrolysis to oil machine; | Year: | 2019; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Payment Terms: | L/C,T/T,Western Union,MoneyGram,Alipay; |

| Showroom Location: | Egypt,Turkey,Brazil,Indonesia,India,Mexico; | Warranty: | 2 years; |

| Key Selling Points: | Multifunctional; | Certification: | CE&BV&SGS; |

| Condition: | New; | Application: | Oil Product; |

| Applicable Industries: | Manufacturing Plant; | capacity: | from 5 tons to 12 tons; |

| Finished products: | Tyre oil&Carbon black&Scrap steel wire&Flue gas; | Tire Machine Type: | Tire Recycling Machine; |

| After-sales Service Provided: | Free spare parts; | Port: | Any Port of China; |

| Oil yield rate: | 45%-55%; | Place of Origin: | China; |

| Automatic Grade: | Automatic; | cooling system: | water cooling system; |

| Weight (KG): | 40000 KG; | Power (kW): | 300 kW; |

| Dimension(L*W*H): | 10800*2800*2800; | Voltage: | 380V/HZ; |

| end products: | diesel oil&gasoline; | Brand Name: | Yuxi; |

Newest Green Energy Plastic Pyrolysis To Oil Machine

What we can get from waste tires?

No. | Name | Rate of output | Use |

1 | Tyre oil | 45% | Can directly to sell Can use distillation equipment get gasoline and diesel Can be used as a fuel |

2 | Carbon black | 30% | Can directly to sell Using carbon black refining equipment to get fine carbon black You can use the carbon black particle granulation equipment |

3 | Scrap steel wire | 15% | Can directly to sell Can use hydraulic baling press do produce a piece of easy transportation and storage |

4 | Flue gas | 10% | Can pass gas spray gun used as fuel Excess gas can be storage system storage |

♥. Carbon black: used for construction bricks with clay also can be used as fuel.

♥. Fuel oil: Widely used as fuel oil in industries such as steel and iron factories, ceramics or chemical industries or hotels, restaurants, etc. or used for generators to get electricity.

♥. Steel wires: Sold or reprocessing

♥. Combustible gas: Can be recycled and used during the process as fuel.

Guarantee of Plastic pyrolysis to oil machine

Overall quality assurance two years (except wearing parts under normal operation, free maintenance), life long maintenance. Host the Q245R boiler steel plate, can bear a high temperature of 700 ℃.

Product Description of Plastic pyrolysis to oil machine

♥. Plastic pyrolysis to oil machine is a new type of tyre oil treatment machine researched by our company through many times of experiment combined with the actual situation. The whole treating process is going under low temperatures. It can effectively remove the tiny particles and Colloidal matter in the tyre oil, and meanwhile, it can remove the odor of the oil, and finally makes the oil color looks clean and transparent and improve the economic value. It features a high recycling rate, low costs of energy consumption, good oil processing ability. It is suitable for the purification of tire pyrolysis oil.

♥. We manufacture tyre recycling plants with advantages of strict quality control that every material part is guaranteed with a lab test, and export to 20 countries with a quite nice customer feedback; we will send expert staff to your factory for installation until you are satisfied with the operation and final products.

Application and raw materials of Plastic pyrolysis to oil machine

No. | Material | Mark |

1 | Scrap tire |

|

2 | Waste plastics | PE, PVC, paper mill washing plastic |

3 | Waste rubber | Sole scrap, scrap cable skin |

4 | Oil sludge, sludge |

|

Tips:

♥ a. The tyre oil can be sold directly or use the distillation machine refining again. After refining, the end product is gasoline and diesel; we also can supply the distillation machine.

♥ b. The carbon black can be sold directly or use the carbon black refining machine to refine again. After refining, the carbon black can be 300-1000mesh or 1000-2500mesh. We also can supply the carbon black refining machine.

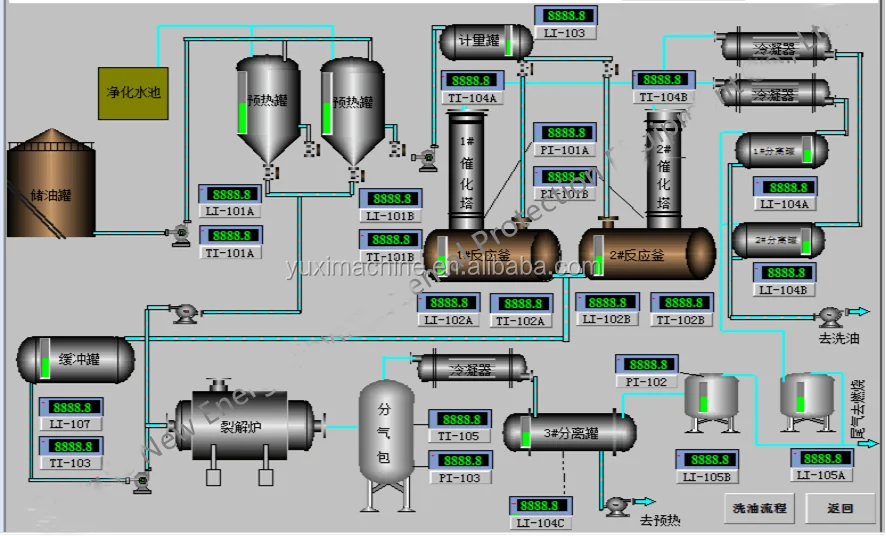

Mani parts of Plastic pyrolysis to oil machine

1. main engine horizontal type revolving split processor.

2. Horizontal-fixed distillation Processor.

3. Feeding-in system

4. Tapping system

5. Central electrically controlled system.

6. Condensation system.

7. Every oil refining system.

8. fuel gas heating system (waste gas processing system).

9. Wastewater processing system.

10. Flue dust removal system

Competitive Advantages of Plastic pyrolysis to oil machine

♥. Reactor: Adopts automatic welding machine, X rays detection and heating treatment which will not only guarantee the quality of welding but also greatly improve working efficiency.

♥. Vacuum Degas & Dewater: Vacuum degassing and dehydration technology which can remove the harmful gas and free water in the waste oil to make sure it can be reused.

♥. Waste Gas Treatment: The advanced waste gas treatment technology is environment-friendly, which will prevent our surroundings from being polluted.

♥. Fully automatic Feeding System: The automatic feeding system can decrease the labor intensity.

♥. Operation personnel quantity: Artificial feeding: need 3-4 workers.

♥. Energy conservation: recycling of waste gas to heat reactor again can save energy and thereby reducing costs.

♥. Security: our equipment has an anti-blocking device and has pressure gauges, alarms, and safety valves.

The principle introduction of Plastic pyrolysis to oil machine

Pyrolysis is the thermochemical decomposition of tyre and plastic polymer since waste tyre and plastic are long-chain polymers containing more than 50,000 carbon atoms. The process will require an initial fuel source of coal, wood or oil. Oil gas produced flows through several successive condensers where the gas is cooled and oil gas is condensed into the oil.

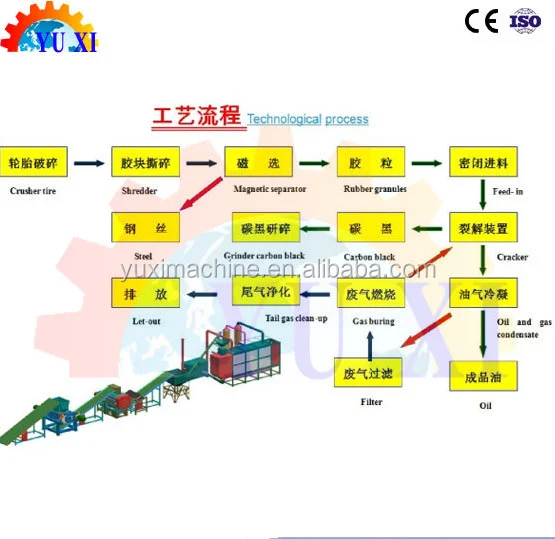

The technological process of Plastic pyrolysis to oil machine

♥. 1. Make reactor rotate clockwise 0.4r/min, put raw material into the reactor, close the feeding door.

♥. 2. Burned the fuel material (coal, wood, natural gas or oil) in the furnace. The reactor will be slowly heated, when the temperature reaches around 180°C, oil gas will come out, then go to the cooling system and get liquid oil. Some incondensable gas that can’t cool down will be lead to the furnace through a gas pipe. It will be used to heat the reactor which can save your energy. Only the first 2 hours use energy for heating. After the first 2 hours mainly use gas, little energy is OK. After pyrolysis, all the oil gas comes out from the reactor, the temperature will fall down. Then make it rotate anticlockwise, carbon black dischargingbegin.

♥. 3. When the temperature deduces to 50°C, the worker can open the door of the reactor to take steel wire out.

♥. 4. And then you can start the next batch.

Packing&Shipping of Plastic pyrolysis to oil machine

We can offer standard exporting packing for long distance sea transportation, wooden case with steel frame, it not only can protect machi Small hydraulic interlocking brick machine from damage, but also can guarantee smoothly pass the exporting inspection.

Our thoughtful service of Plastic pyrolysis to oil machine

Why us?

♥. How about the quality of machines?

Our machines adopt advanced technology. Moreover, we carry out strict supervision during production and make sure every finished product with high quality.

♥. About the delivery time?

Generally, it will be about 20-25 days days after your deposit, which also will be on basis of your order.

♥.What is the packing for the machine?

It depends on your ordering quantity. For sample orders, we advise iron case or plywood case packing to protect the machine from damaging during loading and shipping. For full container load orders, nude packing is ok.

Welcome to visit our factory and test our machines.

Thank you!

-

1-6 axis/shaft type rubber gasket cutting machine for gaskets or rubber rings

-

Rubber pressure bladder for Almex Eupno Beltwin vulcanizing presses

-

Metal Plastic Crusher Biaxial Pet Bottle Grinding Multifunctional Tire Shredder Tire Crusher

-

Factory Direct Sales Truck Radial Tire Retreading Machine/Tyre Retreading Equipment

-

Scrap Tire Sidewall Polishing Machine Circular Cutting Blade

-

Waste Tire Recycling Machine Tire Pulverizer Machine for Rubber Pulverizer

-

Scrap Big Truck Tire Sidewall Cutting Machine Mechanical Recycling Tire Cutting Machine Recycling Machine

-

open mixing mill

-

UT-A2100 Portable Heat Press Machine PVC Conveyor Belt Vulcanizing Machine Air-cooled Crimping Machine

-

Rubber floor tile vulcanizing machine/rubber floor mat making machine

Other Products

-

Newly designed waste tire recycling machine for rubber powder tire recycling machine production line$35600.00 / set

Newly designed waste tire recycling machine for rubber powder tire recycling machine production line$35600.00 / set -

$25600.00 / set

$25600.00 / set