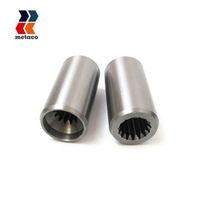

Aluminum Accessories 12 Sleeve Spline Coupling 17 Teeth Flexible Spline Shaft Coupling

-

Supplier: Shenzhen Perfect Precision Products Co.,ltd -

Region: Guangdong, China -

Contact: Ms Echo Yu -

Price: $1.00 / >=2 pieces -

Min. Order: 2 pieces

| Product name: | Cnc Part; | Place of Origin: | China; |

| Applicable Industries: | Building Material Shops,Machinery Repair Shops,Farms,Home Use,Construction works ,Energy & Mining; | Application: | Auto Part; |

| Material: | Aluminium; | Brand Name: | Custom; |

| Service: | Customized OEM; | Packaging Detail: | Aluminum Accessories 12 Sleeve Spline Coupling 17 Teeth Flexible Spline Shaft Coupling Standard export carton or based on customer's requirement.; |

| Supply Ability: | 10000 Piece/Pieces per Month; | Name: | Aluminum Sleeve Coupling 17 Teeth Flexible Spline Shaft Coupling; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Paypal; | Material: | Aluminum; |

| Process: | CNC Turning; | Port: | Shenzhen; |

| Structure: | Metal Bellows; | Keywords: | Flexible Spline Coupling; |

| Item: | Accessories 12 Spline Coupling 17 Teeth Flexible Spline Shaft Coupling; | Flexible or Rigid: | Flexible; |

| Standard or Nonstandard: | Nonstandard; |

Aluminum Accessories 12 Sleeve Spline Coupling 17 Teeth Flexible Spline Shaft Coupling

| Material and Testing Report | ||

| Metal | Aluminum | Aluminum 2024 Aluminum 5052 Aluminum 6061-T6 |

| Aluminum 6063 Aluminum 7075 Aluminum MIC 6 | ||

| Stainlesss steel | 200series 300series 400series 500series UNS S32101 | |

| UNS S32304 UNS S32003 UNS S31803 UNS S32205 | ||

| UNS S32760 UNS S32750 UNS S32550 UNS S32707 UNS S33207 | ||

| Steel | 12L14 4140 1018 1045 12L14 4130 4142 ,O1 tool steel, | |

| D2 tool steel,A36 1008 ,Alloy42 | ||

| Titanium | Grades 1-4 Grade 5 Grade 9 | |

| Brass | 260, C360 | |

| Copper | ||

| Bronze | C932 | |

| Carbon fiber | ||

| PTFE | Polytetrafluoroethylene (PTFE) | |

| Plastic | Acetal | (Polyoxymethylene (POM)) [Delrin] |

| PEEK | Polycarbonate | |

| Polystyrene | Polyether Ether Ketone | |

| Nylon | ||

| ABS | ||

| PVC | ||

| Acrylic | ||

| G-10 Garolite Fiberglass | ||

| Finish Result | |

| As Machined | Sharp edge and burrs will be removed |

| Bead Blast | The part surface is left with a smooth, matte appearance |

| Anodized | Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and is usually associated with aluminum. |

Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II. | |

| Powder Coat | This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic. |

| Customized | Cotact us via email,skype,whatsapp. We will look into a finishing process for you. |

Others | |

| Tolerance | +/-0.005mm |

| Lead Time | 1-2 weeks for samples,3-4 weeks for mass production |

| Drawing Accepted | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TI |

| Payment Terms | Trade Assurance, TT/Paypal/WestUnion |

| Our Workshop | MULTI-AXIS CNC MILLING CENTERS | 5 Axis Machining 4 Axis Machining 3 Axis Machining |

| CNC LATHE AND LIVE ACTION TOOLING | Dual Spindle Lathes | |

| Waterjet Cutting and Wire EDM AVAILABLE UPON REQUEST | ||

| Welding | weldment service for Aluminum, stainless steel, brass,copper and so on | |

| Laser Cutting | Laser beam vaporizes cut path | |

| Laser engraving | Logo laser printing | |

| Punching Stamping | Successive punching of fixed shapes | |

| Bending | Bends sheet metal to an angle | |

| Knurling | ||

| Reaming | ||

| Threading & Tapping |

-

Flexible Coupling VS110 Rexnord-Falk VIVA Elastomer Coupling

-

L035 L050 L070 L095 rubber coupling with jaws

-

Jaws Love Joy

-

Industrial High Quality Star Flexible Shaft Coupling Claw Coupling

-

SWC-BH type high-speed universal coupling universal drive shaft

-

SLGR MINUC065 SWC-I100DH-304+30 power output cardan shaft finishing engineering machinery shaft

-

Automobile Steering System Axial Formed Alloy Steel Spline Coupling

-

Flexible gr rotex 38 KTR GS GR coupling rubber spider pad

-

Factory direct powder metallurgy sintered steel spline coupling

-

Drum Gear Shaft Coupling For High Speed Turbine Gear Coupling China Factory

Other Products

-

$200.00 / piece

$200.00 / piece -

$8.00 / piece

$8.00 / piece -

$0.30 / piece

$0.30 / piece -

$0.30 / piece

$0.30 / piece -

$9.98 - $13.80 / piece

$9.98 - $13.80 / piece -

$0.99 / piece

$0.99 / piece -

$0.10 / piece

$0.10 / piece -

$0.99 / piece

$0.99 / piece -

$1.00 / piece

$1.00 / piece -

$0.10 / piece

$0.10 / piece