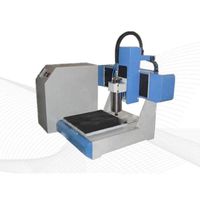

Pneumatic metal engraving and marking machine Aluminum copper mold, shoe mold

-

Supplier: Jinan Bcamcnc Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Ms Christina Wang -

Price: $7599.00 /set -

Min. Order: 1 set

| Application: | metallic materials; | After-sales Service Provided: | No after-sales service; |

| Warranty: | 3 years; | Brand Name: | BCAMCNC; |

| Place of Origin: | Shandong China; | Spindle power: | 5.5kw; |

| Main Axle Rotational Speed: | 6000-24000rpm; | Weight: | 2000KG; |

| Design software: | Artcam/Ucancam/Type 3; | Spindle speed: | 24000rpm; |

| Certification: | CE ISO; | Applicable Industries: | Machinery Repair Shops,Manufacturing Plant,Advertising Company,Mould Fabrication making; |

| Rated Power: | 5.0KW; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Dimensions: | 1.4*1.5*1.5mm; | Packaging Detail: | Inner package:stretch film. Outside package: standard plywood case; |

| Name: | pneumatic metal engraving and marking machine; | Port: | qingdaqo guangzhou shanghai; |

| Milling Cutter Diameter: | 3.175-12.7mm; | Machine body: | Whole cast iron; |

| Feeding Height: | 170mm; | X Y Z working size: | 600*600*150mm; |

| Supply Ability: | 100 Set/Sets per Month Aluminum sheet metal engraving machine; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; |

| Engraving Speed: | 10m/min; | X Y Z transmission: | High precision ball screw; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Movement style: | Gantry fixed, table move; |

| Condition: | New; | X Y Z guide rail: | HIWIN linear square guide rail; |

Technical Parameters

Parameters | Standard Specifications BCM1325S |

X,Y,Z Working Area | 1300*2500*200mm|4′*8′ |

| Optional Working Area | 1300*1300*200mm|4′*4′ |

| Optional Working Area | 1500*3000*200mm|5′*10′ |

| Optional Working Area | 2000*3000*200mm|6′*10′ |

| Optional Working Area | 2000*4000*200mm|6′*13′ |

| Optional Working Area | 2000*6000*200mm|6′*20′ |

Spindle Power | 3.0kw water cooling spindle |

X,Y,Z Traveling Positioning Accuracy | ±0.03/2000mm |

Table Surface | Vacuum table+T-solt table |

X,Y,Z Rail and Trasmission | X Y axis gear transmission, Z axis TaiwanTBI Ball Screw |

Max. Rapid Travel Rate | 50m/min |

Max. Working Speed | 30m/min |

Cutting thickness | According materials |

Spindle Speed | 6000-24000RPM |

Drive Motors | 4 sets High Torque stepper motor and drivers |

Working Voltage | AC220v0r380v/50HZ/3 phase,220v/1phase/50hz |

Command Language | G Code |

Operating System | Richauto A11 DSP control system |

Interface | USB |

Software Compatibility | Option:BCAMPRO/VCarve/VCarvePro/UcanCAM/ArtCAM,etc. |

Running Environment | Temperature: -20℃~45℃ Relative Humidity: 5%~75% |

Machine configuration

- Working area: 1300*2500*200mm|4′*8′

- CE standard

- 5.5kw water cooling spindle(Option: 5.5kw,6.0kw ,7.5kw Quick-Release Spindle)

- Delta Inverter

- 3.0kw double dust collector +Dust collector pipe+Dust collector support

- Rich auto A11 control system

- Vacuum table + T-solt table + 5.5kw water pump

- 8mm Heavy duty frame

- Active safety system

- X ,Y axis gear transmission, Z axis Taiwan TBI ball screw transmission

- Taiwan Hiwin 25 rails

- Schneider Electronic spare parts

- Automatic lubrication system

- Japan Omron limit switch

- High torque stepper motor and drivers

- Tool height sensor

- Standard box of tools

More Machine Details

1. Machine structure

Whole machine table adopts high strength thick steel pipe welded. Whole working table cast by resin sand. The annealing and other heat treatment methods ensure that the whole structure is tested to the limit for sturdiness and reliability.The whole machine made by CNC gantry machining center to ensure the structure basic precision. After strict quality control, the structure treated with deoil and pain process. After various process of painting, the construction can be used for assembly.

2. Changsheng Water-cooling spindle

Affordable, low noise, good water cooling, suitable for hard wood, stone, soft metal high temperature operation.

3. RichAuto A11 DSP control system

The handle operation does not require a computer connection, especially for beginners.

4.TBI imported ball screw

TBI imported ball screw has reached level C grinding. It is durable, with low friction coefficient, low noise. With high positioning accuracy, flexibility, stability and other advantages. With heat treatment, so it is with advantages of antioxidant, anti-corrosion, with thousands of hundreds of test, the lifetime is up to 10 years.

- Airtech pro dust collector: our new deaign to vacuum, and it is very clean to absorb wood dust.

- Vacuum pump: Oil free pump 5.5Kw/Air pump 5.5Kw

- CAM Software: VCarve/VCarve Pro/ArtCAM/UcanCAM,etc.

- CW3000 water chiller: dedicated to water-cooled spindles

Advantages:

1.Whole cast iron structure, the body will not transform for long use.

2. X Y Z use 25mm HIWIN linear square guide rail, it is more stable than the normal round one.

3.X Y Z transmission use high precision ball screw, avoid the spindle suddenly up and down.

4.Gantry fixed,table move design make the machine more precise.

5. Imported control system,higher precision, easier and more convenient to operate.

6. ESTUN servo motor and driver, break-point memory makes sure accidental workng and avoid the waste of materials.

7.X axis has steel cover,keep the machine clean and long life.

More details:

Applied material:

Iron,aluminum,copper electrode and graphite,stainless steel,etc.

Ideal for

-advertising industry

-mold industry

-printing industry

-decoration industry

-clock and watch industry,etc.

Cutting sample:

BCMANC Information

BCAM was located in Jinan,shandong province,covers the area of 6000 square meters. BCAM group is manufacturing and research and development of the company that focus on CNC engraving machine and cutting machine for many years. Now we have mature production workers more than 50 people, 8 sales teams,2 product research and development teams,2 after-sales service teams.Products exported to Europe,America,Australia,Africa,Asia. We set up an overseas warehouse in Dubai in 2017, and we have exclusive agents in Europe, France, Germany, UK, Poland and many other countries.

Q1. Delivery time of CNC router machine?

Aplus and S series standard size and configuration CNC router machine delivery time is 5 days, C,D,E series machine delivery time is 7 days, F,4 axis and 5 axis series machine delivery time is 20 days. So we suggestion client pay 100% money, because we can can arrange machine delivery immediately.

Q2. Can you sent machine to my home?

Yes, we have cooperation long time shipping agent, famous team in China, them can offer FCA,FOB, CIF, DDU, DDP price, usual suggest receiver address is Business district, usual less big car drive in the Civil area.

Q3. This is the first time to use cnc router machine,is it easy to operate?

Yes, it is easy, if you can draw with software, the machine operate is no problem, because we will support:

1).English guide video and instruction book are sent to you free together with the cnc router.

2).Free training course in our factory. Engineers are available to serve overseas but all the expense needs being paid by your side.

3).We have our own after-sales service team,24 hours technical support by calling, video and email.

Q4. Can you please tell me if it’s possible to make a 1325C machine with 240v single phase? If so what is the power consumption?

The power consumption of 240V/single phase and 380V/3Phase is same(but the power of a single phase voltage pump is limited to no more than 3kw). I recommend you choose 3 2.2kw air pumps. We will adopt some machine parts different from 380V because of 240V current will become bigger.

Packaging & Shipping:

1.Standard plywood case, its compressive strength and bearing quality is better.

2.The board area is bit, the soil structure is good, it is better in leakproofness and waterproof.

3.When importing, the plywood case is with fumigation-free, the procedure is simple.

4.Delivery Detail: within 20days after received your payment

--Firstly,plywood case,its compressive strength and bearing quality is better,it is the market of choice for the goods of high-weight packaging

-

Voiern 20w 30w 50w 100w ring engraving machine and metal fiber laser marking machine with MAX JPT RAYCUS laser source

-

Pneumatic dot peen marking machine Eetal nameplate engraving machine metal serial number engraving machine

-

2022 New Mini Portable Laser Engraver Cutting Machine For Wood Leather Plastic Engraving OEM Logo Brand

-

Dot peen marking machine cylinder material dot peen marking machine nameplate dot peen marking machine

-

Fully automatic portable electric mini dot peen marking machine

-

Small CNC Metal Medal Making Machine Price

-

Mini 3030 4040 desktop cnc engraving machine engraving and milling machine

-

Automatic Portable Electric Mini Pointing Needle Marking Machine High Quality Pneumatic Marking Machine

-

Desktop point needle automatic metal CNC engraving machine metal

-

small size vin number SC-25*90 handheld dot peen chassis marking machine

Other Products

-

$7000.00 / set

$7000.00 / set -

$18299.00 / set

$18299.00 / set -

$6460.00 / set

$6460.00 / set