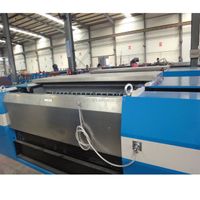

Automatic transporter type rack copper nickel zinc chrome electroplating line plant

-

Supplier: Jiangsu Kangpin Electrical Technology Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr. Alex D -

Price: $50000.00 /set -

Min. Order: 1 set

| Application: | zinc, copper, nickel chrome plating,anodizing; | Condition: | New; |

| Payment Terms: | T/T; | Port: | SHANGHAI; |

| Surrounding equipment: | Rectifier, Filter, Chiller,Heater,Titanium basket,Temp controller,; | Place of Origin: | Jiangsu China; |

| Packaging Detail: | Strong wooden box for export; | Brand Name: | KENUO; |

| Weight: | actual weight; | Material: | PP, PVC ,SUS304,carbon steel,etc; |

| Operation type: | automatic,semi-automatic,manual; | Warranty: | 1 year; |

| After-sales Service: | Engineers available to service machinery overseas; | Certification: | CE SGS ISO9001; |

| Power(W): | actual power; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; |

| Voltage: | 380V; | Heating model: | elecrtric,hot water,steam; |

| Plating style: | rack plating,barrel plating; | Supply Ability: | 5 Set/Sets per Month; |

| Dimension(L*W*H): | actual size; | Applicable Industries: | Manufacturing Plant; |

| Plating Style: | Electroplating with chemicals; |

Product Application

The Plating Line can be switched either full automatic or Semi-Automatic,which applies to various kinds of hardware,electronics,fasteners, ABS,automobile and lighting industries etc.The main electrical parts we usually adopt European or Japanese brands.For other parts,such as the plating barrel,frame,tank,rectifier,pump and filter,and the electrical control cabinet,we can provide you our own registered brand products.

Main Features

2.Material of transporter: SUS304, SUS201, Carbon steel

3.Material of framework SUS304, SUS201, Carbon steel

4.Process Model: Automatic, Semi – automatic, Manual

5.Control system: PLC, PC, PCS, Computer control

6.Heating model: Electronic, Steam, Hot water

7.Surrounding Parts: Rectifiers, Filters, Pipe, Air blower, waste gas treatment system ect.

8.Advantage: Flexible design, safe, stable and high strength

9.Application: nickel, copper, zinc, chrome, gold plating for metal and plastic

Plating crane/Gantry/Hoist:

It is designed and manufactured by factory with low noise, stable running and durable, safe and efficient.The crane is with high precision locating system and safety protection.

Plating tank:

It is designed and manufactured by our factory with strong structure and long lifetime.It will be used to storage the water,acid/alkaline chemicals,nickel/copper/zinc/chrome chemicals,etc.This is the basic of plating line.

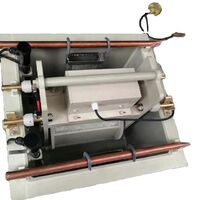

Plating rectifier:

The swith mode air/water cooled rectifier is designed and manufactured by us.The rectifier can offer stable Amps and Volts for the plating line and make sure to get good plating product.This is the key of plating line.

Ventilation system:

The air scrubber is (waste gas treatment tower) assemblied and placed customer's factory.The ventilation way is integrated exhaust system which is of high efficiency and satisfactory. And the air ducts and gas hoods are all made of PP, releasing the waste gas to avoid mutual contamination with staff and equipment.

Plating filter:

Offered by well-known brand"MIKAWA",good and stable quality.The purpose is to filter the chemical to remove the impurities, the plating would be smooth. The chemical will be mixed as well to ensure the temperature and density are evenly distributed, resulting in a homogenous plating

Pure water/DI water system is used to offer pure water rinse for plating line.

The Automatic dosing system is used for adding chemicals by PLC controller.

The enclosed frame by steel and transparent PVC for environment protection.

The FRP grid sheet for walking platform.

1. Project design and 3D simulation

2. Manufacturing and shipment

3. Installation and commissioning,teaching

4. After-sale service and long lifetime technical support

1. Q: What is the necessary information for design?

A: The capacity of your per products/material/weight&size/surface area;

The thickness of plating layer, working hours per day, salt spray test and time,

Theworkshop dimension and so on.

2. Q: What is the lead time for one project?

A:Mormally it will take 30 days for production and the time is based on the project.

3. Q: How could I carry out my work if I plan to set up a new plating line?

A: It would be better if we could communicate with your chemical liquid supplier on the process details first. Besides, professional engineer is also important for your project.

-

Hebei Xingxiang steel wire galvanizing machine galvanizing machine

-

Gold Plating Silver Chrome Plating Machine Silver Chrome Plating Machine Rose Gold Chrome Plating Machine

-

Efficient aluminum anodizing and electroplating production line

-

Small electroplating machine

-

Electroplating hard chrome equipment electroplating machine rectifier air-cooled electrolytic electroplating power supply

-

Decolorizer

-

12v 500A Precious Metal Plating Rectifier

-

New Products Feiyide Electroplating Machine Small Bucket Copper Nickel Zinc Electroplating Metal Electroplating Machinery

-

Hannie Plating Equipment Barrel Plating Tank Anodizing Kit Barrel Plating Plant

-

Tongda11 mini electroplating machine Plating Line chrome plating system of small nickel electroplating tank