Automatic fast speed double side bopp film laminating machine

-

Supplier: Hangzhou Fuyang Sigo Office Supplies Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Ella Ju -

Price: $1000.00 /unit -

Min. Order: 1 unit

| Single package size: | 102X89X111 cm; | Driven Type: | Electric; |

| Auto feed paper with belt: | Yes; | Delivery Detail: | 0 days after payment; |

| Type: | Laminating Machine; | Max. Laminating speed: | 10m/min; |

| Condition: | New; | Packaging Material: | Paper; |

| Package Type: | Automatic fast speed double side bopp film laminating machine 1pcs/ Wooden carton Carton Dimensions: 160*110*135cm G.W: 130KG N.W: 100KG; | Automatic Grade: | Semi-Automatic; |

| Cold&Hot Laminting: | Yes; | Single gross weight: | 130 KG; |

| Weight: | 130KG; | After-sales Service Provided: | Free spare parts,Online support,Video technical support; |

| Speed Control: | LCD Screen; | Warranty: | 1 Year; |

| Selling Units: | Single item; | Voltage: | 110V/220V; |

| Laminating temperature: | 60~150°C; | Dimension(L*W*H): | 102*89*111cm; |

| Max. Laminating width: | 490mm; | Place of Origin: | Zhejiang China (Mainland); |

| Laminate Thickness: | 60-800gsm; | Product name: | Automatic fast speed double side bopp film laminating machine; |

| Packaging Type: | Film; | Application: | Apparel,Commodity,Machinery & Hardware,Textiles; |

| Package Preview: | https://sc02.alicdn.com/kf/HTB1LffmP7voK1RjSZFNq6AxMVXa1.jpg_640x640.jpg; | Heating Roller: | Big Steel Roller; |

| Brand Name: | SIGO; | Certification: | CE ISO9001; |

| Single&Double Sides Laminating: | Yes; |

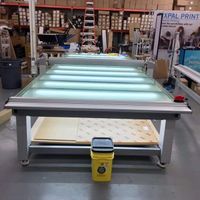

SG-490 A2/A3/A4 Semi-Automatic Electric Laminating Machine With Auto Feed Paper

.

This machine covers a small area, is operated conveniently, run fast. It's equipped with automatic temperature-control and speed-regulation, automatic feeding. Several rolls or redundant rolls can be slit at one time, so this machine is regarded as a slitter.

The machine adopts pre-coated film as the material. It is widely used for lamination on the surface of window packing paper boxes, various books, maps, pictures, certificates, holographic cellphone etc. After the above products are laminated, they have the features of water-resistance, clear graphic arts and strong three-dimensional sense.

SG-490 Electric Laminating Machine YouTube Video Link: https://youtu.be/SWA4bMiuuxQ

Details Parts

Hangzhou Fuyang Sigao Office Supplies CO., LTD was founded in 2003. Our company is a synthetical enterprise occupying more than ten thousand square meters of factory building. We own import and export right.

The major products of our corporation are text binding machines, paper processing machinery, and various of file folder/binding materl (Binding plstic comb, double loops wire, spiral coil, paper cover, PVC cover, slide binder,etc). In addition, we also deal with office consumption, such as cover paper of binding,clamp bars, plastic and rubber rings, and iron rings. Our products have won high reputation among customer at home and abroad for the reliable performance and novel design.

Welcome to visit our company and cooperate with us.

How does your factory do regarding quality control?

Quality is priority. Our factory always attach great importance to quality controlling from the verybeginning to the very end. Our factory has gained CQC, ISO, SGS,FSC authentication

Where is your factory located?

Our factory is located in Hangzhou City, Zhejiang Province, China, around 1 hours train from Shanghai .Around

1hour from "Hanghou Internatil Airport "to our factory. All our clients, from home or abroad, are warmly welcome to visit us!

What's the material of laminator body ?

Hot sale YYFM, QDFM series hydraulic lamianting machine very strongly. The roller imported from abroad to guarantee the quality.

How can i get some samples?

We are honored to offer you sample!

You should charge for freight & laminating machin.

What's the terms of payment?

We accept T/T, Westunion, Credit Card, T/T Checking, Paypal. Just for your choose.

Less than USD10,000, you need pay 100% in advance. Large than USD10,000, we accept 30% in advacne, 70% before shipping.

Are you a factory?

Yes.We are factory at Fuyang, Hangzhou City ,We wainly produce binding system/ cutting system/laminating system/office products and material,etc. any time welcome visit us.

-

EC-650 Economical and practical electric semi-automatic cold laminating machine

-

High quality RFID chip card making machine

-

Fayon 1600DA 160cm Automatic High Speed Cold Laminator Roll Laminating Machine Cold Laminator

-

Hangzhou Befitter HT-650 650mm 25" Automatic Hot Foil Transfer Laminator

-

Cheap price large format fayon smart workbench 1325 flat laminator workbench flat laminating machine flat laminating machine

-

SWFM520C 485mm fast hydraulic manual paper feeding automatic cutting and laminating machine 0-25m/min

-

L0 Wide Format Smart FY916 Manual Cold Flat Laminator

-

Hot selling double-sided adjustable speed manual a2 a3 hot and cold laminating machine laminating machine price

-

Automatic roll laminator/Automatic roll laminating machine

-

L388 automatic roll to roll roller laminating machine with metal roller paper hot roll laminating machine for printing shop

Other Products

-

$495.00 / piece

$495.00 / piece -

$620.00 / unit

$620.00 / unit -

$230.00 / piece

$230.00 / piece -

$850.00 / set

$850.00 / set -

$288.00 / unit

$288.00 / unit -

$125.00 / piece

$125.00 / piece -

$82.00 / piece

$82.00 / piece -

$1450.00 / piece

$1450.00 / piece -

$900.00 / unit

$900.00 / unit -

$560.00 / piece

$560.00 / piece