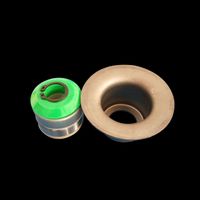

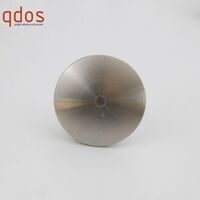

OEM stainless steel high quality bearing housing for bearing assembly

-

Supplier: Qingdao OS Machinery Manufacturing Co., Ltd. -

Region: Shandong, China -

Contact: Ms. Julie Yu -

Price: $8.00 / >=10 pieces -

Min. Order: 10 pieces

| Material: | Stainless Steel304/316; | Package Type: | cartons/non-wood boxes/pallets or per customers' requests; |

| Package Preview: | https://sc01.alicdn.com/kf/HLB1V4V9apzsK1Rjy1Xbq6xOaFXah.jpg_640x640.jpg; | Machining Process: | CNC&Machining center; |

| Material: | Stainless Steel; | Service: | Customized OEM; |

| Usage: | bearing; | Place of Origin: | Shandong China; |

| Brand Name: | QDOS; | Packaging methods: | plastic bags and cartons; |

| Single gross weight: | 0.9 KG; | Single package size: | 42X21X12 cm; |

| Selling Units: | Single item; | Name: | bearing seat assembly; |

| Product Keywords: | bearing seat; | weight: | 0.9kg; |

| Model Number: | QDOS026; | Brand: | QDOS; |

| Application: | Industrial; |

Machining Accuracy(Precision) | Item |

Machining capacity | CNC turning |

MOQ | 5pcs |

Special features | Nice appearance Long term corrosion-resistance properties Accurate tolerances |

Application | bearing assembly |

| Material | Stainless steel (304SS,CF8M,316SS,316L) |

| Inspection | ID and OD Mitutoyo micrometer, special gages for GDT tolerances |

| Packaging Methods | Bubble bag for each pc, 25pcs in one carton, then 40cartons on one non-wood pallet, total weight less 600kg |

| Product Weight | From less than 0.4kg till 25kg+ |

| Production Process | Investment casting—solution anneal treatment-CNC machining—dimensions inspection—final inspection—packaging--randomly checking--shipment made |

Qingdao OS machinery manufacturing Co, Ltd is a professional manufacturer for casting, polishing, precise machining, assembly.

QDOS is keen on satisfying the requirements of customers. What we can do are:

1. To provide small orders but more varieties of personalized production services;

2. To provide the appropriate technical support based on the customers needs;

3. To recommend a reasonable processing technology based on the customers’ demand and products’ features,.

4. To ensure the comprehensive competitiveness of customer products.Our company philosophy is Honesty, Gratitude ,Duty, Responsibility, Courtesy, Win. We would like grow up with every customer according this philosophy.

1.Can you provide OEM production processing and product services?

The company has its own factory and professional foreign trade business department, which can carry out customized processing of products, production and improvement of processing technology, control of costs, and improvement of quality. Enterprises can sample and map manufacturing products according to the needs of customers, that is, we are Professional OEM manufacturer.

The foreign trade business unit is the bridge between the company and its customers: it accepts the feedback inquiry, the progress and quality of the samples and batch orders.

2.What information can I provide before purchasing a product to place an order?

Can provide the relevant product models, specifications, prices, quality inspection methods, maximum and minimum set up, packaging, transportation options.

3.How to choose products to meet our needs?

We can produce products with a very clear and detailed product catalog and product description. You can choose according to your actual needs in the product catalog and will send us an inquiry or email or phone. We will give you a satisfactory reply within 1 working day after receiving any of your information.

4.Which industries do the purchased products apply to?

We are a professional OEM manufacturer. Our products are widely used in machinery, medical, chemical, shipbuilding, construction, food and other industries. As long as there is a demand for spare parts, we can process it for production.

5.How to ensure the quality of OEM products?

Our OEM services include: sample customization and custom drawings

(1) Customization: Our engineering designers will use 3D to plot the size and characteristics of the sample, plot the AUTOCAD and 3D model, send it to the customer for confirmation, and start the production of the mold or product.

(2) To customize the plans: We receive drawings from our customers to check if all tolerances and features are satisfied. If possible, we will start production and processing of molds and products.

In order to meet the needs of customers, we have corresponding production and processing equipment and testing methods.

Machining equipment: Mazak CNC vertical and horizontal machining centers: 3 sets Tolerances can be controlled within +/- 0.005mm

CNC Lathe: 4 sets of tolerances can be controlled at +/-0.015mm

Detection means: CMM (subcontract)

Mitutoyo inside diameter dial indicator: 18

Mitutoyo outside diameter dial gauge: 20

Digital display percent caliper: 10

-

High quality seated bearing F209 Insert ball bearing supplier F209

-

Gray cast shell, radial insert ball bearing with seat P210

-

High Quality Bearing Parts S2202 2RS Bearing Housing

-

Wholesale stamped bearing housing deep groove ball bearing stamped bearing housing

-

China Bearing End Cover TK89-6204 Belt Conveyor Idler Roller Accessories

-

Trinity Premium TKll6204-108 Construction Site Bearing Covers and Labyrinth Seals

-

Idler bearing housing DTII6204 -89 and related seals

-

Stamped DT II steel housings for bearings

-

Plastic end roller bearings/roller end housings for conveyors

-

High quality conveyor roller bearing housings 6204 for conveying systems

Other Products

-

$4.00 / piece

$4.00 / piece -

$1.75 / piece

$1.75 / piece