PMMA PC acrylic plastic 3D advertising signage letters bathtub led ceiling light making vacuum forming machine

-

Supplier: Dongguan Junjingsai Packaging Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Mr. Junsai Wei -

Price: $58800.00 /set -

Min. Order: 1 set

| Selling Units: | Single item; | Dimension(L*W*H): | 3300*2800*2500mm; |

| Safety protection equipment: | infrared ray; | Single gross weight: | 68 KG; |

| Power(W): | 150KW; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| Plastic Type: | PS, PE,PC,PP, PVC, PMMA,EPS,EVA,TPU, TPE; | Product Type: | thick sheet; |

| Max. forming height: | 500mm; | Weight: | 10T; |

| Product Name: | Speed Thick sheet ABS PP PE PC vacuum forming machine; | Package Type: | standard exporting package for Factory Supply High Speed Thick sheet ABS PP PE PC vacuum forming machine; |

| Air Pressure: | 0.6-0.8Mpa; | Brand Name: | JUNSAI; |

| Heaters: | heating tube; | Water Chiller: | 5HP; |

| Voltage: | 380V 50HZ 3Phase; | Condition: | New; |

| Sheet thickness: | 1-10mm; | Max. forming area: | 2400*1200mm; |

| Place of Origin: | Guangdong China; | Automatic: | Yes; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Key Selling Points: | Automatic; |

| Warranty: | 1 Year; | After-sales Service Provided: | Field installation, commissioning and training; |

| Certification: | CE/ISO9001; | Power Supply: | 380V/50Hz; |

| Type: | Vacuum Forming Machine; | Single package size: | 150X40X50 cm; |

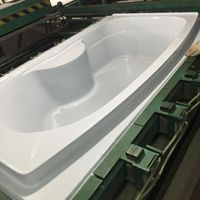

The automatic thick sheet plastic vacuum forming machine is widely applied in 1-12mm of ABS, PP, PE, PS, PC, PVC, EPS, HIPS, HDPE, PMMA, PET, PETG plastic sheet vacuum formed products such, it is an ideal vacuum forming machine for automobile parts like car foot mat, car trunk mat, car bumper, light box, plastic board, plastic containers, plastic pallet, plastic helmet, plastic covers, bathtub, fruit tray, suitcase, apparatus shell, instrument panel, refrigerator inner liners, etc.Can replace injection molding and fiberglass products and save energy and mold costs. Our machine video:

Our machine video:

https://www.youtube.com/channel/UCVhkUPUkHObLG-GWgQY9TVQ/videos

Product Name | thick sheet plastic vacuum forming machine |

Max. forming area | 2400*1200mm customizable |

Max. forming height | 400mm customizable |

Sheet thickness | 1-12mm |

Vacuum Pump Capacity | 100 m³/min |

Heaters | heating tube |

Air Pressure | 0.6-0.8Mpa |

Water Chiller | 5HP |

Safety protection equipment | infrared ray |

Power Supply | 380V/50Hz |

Double Oven | Yes |

Material Loading | Manual |

Material unloading | Manual |

Up Heating tube | 236Pcs |

Down Heating tube | 258pcs |

Up Heating Power | 150kw |

Main Features:

One single heating oven with two work station, JJS2412 is a new price-performance ratio for automatic production class machinesThe reform can save electric power effectively, shorten reclaiming time of invest, reduce operating and equipment cost greatly and then develop enterprises frugally.

1) Digital timer with audible warning helps achieve consistent cycle times.

2)According to consumer's need,PLC control available.

3) programme memory to recall heater profile and timing settings for each project.(PLC type)

4) 30pcs ceramic infrared heating boards which can be controlled separately, suit for different size or different thickness material.

5) 25pcs Solid state voltage regulators, control heating boards simple and visualized.

6) Large-scale cooling fan which can cool the products quickly.

7)Cooling system which suit for thick material.(optional)

8) Manual and Semi-auto style.

FAQ

Vacuum Forming Machine for refrigerator liner. car foot mat car trunk mat vacuum forming machine.Pickup bedliner forming machine vacuum forming , Vacuum Forming Machine for refrigerator inner face .Thick sheet vacuum forming machine for making automobile parts .Full Auto Vacuum Forming Machine for home appliance shell.Thick sheet vacuum forming machine for making car parts.Vacuum Forming Machine for Car Bumper/Refrigerator inner face/Refrigerator liner/Plastic cover

-

Disposable Foam Plate Production Line/Vacuum Forming Lunch Box Making Machine/Fast Food Foam Plate Production Machine

-

Low Price New Plastic Vacuum Forming Machine to Make Disposable Plates/Foam Tableware/Food Containers

-

Used cup machine for vacuum plastic forming

-

Acrylic Forming/Making/Vacuum Tub Forming Machine

-

Durable desktop acrylic pvc plastic vacuum forming machine

-

PS Expanded Styrofoam Pan Container Pan Tray Food Box Small Production Machine, Ellie Whats 008613780912769

-

FUSHI brand PS EPS thermocol foam board container tray mould machine

-

small mini desktop acrylic pvc plastic vacuum forming machine/thermal vacuum forming machine

-

best price vacuum forming machine

-

BSX2030 Super Discount High Modular Acrylic ABS PP Thermoforming Deep Vacuum Forming Machine

Other Products

-

$2800.00 / set

$2800.00 / set -

$75000.00 / set

$75000.00 / set