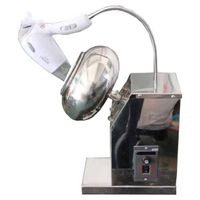

40kg automatic pharmaceutical tablet film sugar coating machine with ISO and GMP approved

-

Supplier: Huizhou Pingfang Trading Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Yanny Wang -

Price: $22000.00 /set -

Min. Order: 1 set

| Usage: | Pharmaceutical; | Coating rattler diameter: | 820mm; |

| Power(W): | 1.1kw; | Condition: | New; |

| Supply Ability: | 100 Set/Sets per Year GMP grade 40kg automatic pharmaceutical tablet film sugar coatin; | Packaging Detail: | In seaworthy wooden case for GMP grade 40kg automatic pharmaceutical tablet film sugar coating machine; |

| Voltage: | 380V; | Product Name: | automatic pharmaceutical tablet film sugar coating machine; |

| Steel Material: | Stainless Steel 304/316; | Place of Origin: | Zhejiang China; |

| Port: | FOB Shanghai; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Max load Capacity: | 40kg; | Features: | Imported by PLC, easy operation; |

| Certification: | ISO GMP CE; | Roation speed of coating ratter: | 2-18; |

| Delivery Detail: | Shipped in 45 days after payment; | Host Configuration dimensions: | 1100x800x1470mm; |

| Weight: | 500; | Payment Terms: | L/C,T/T; |

| Dimension(L*W*H): | 1100*800*1470m'm; | Application: | Pill.tablet, Chocolate coating; |

| Brand Name: | PF; | Warranty: | One Year; |

40kg automatic pharmaceutical tablet film sugar coating machine with GMP and ISO approved

Principle:

The tablets make complicated and constant track movement with easy and smooth turn frequent exchanging in a clean and closed drum of the film coating machine. The coating mixed round in the mixing drum are sprayed on tables through the spray gun at the Inlet un action of the peristaltic pump. Meanwhile under the action of air exhaust and negative pressure 100,000 clean hot air supplied by the air exhaust cabinet is exhausted from the fan at the sieve meshes through tablets. So these coating mediums on the surface of tablets get dry forming a coat of firm, fine and smooth film. The whole process is finished under the control of PLC.

Characteristic:

1,All operations can be finished through pushing the touch key on the computer-controlled panel. The operational panel is a full-sealed slight touch film interface. The main machine as reliable and stable performance.

2,The streamline guiding-type mixer drives tablets to make easy and smooth rotation without fragment and chipped edge, which improves the quality of finished products.

3,Automatic feeding device stopped the cross pollution , convenient to feed, with high efficiency and full direction. The coating boiler equipped in the high pressure spray gun, which can rotate 1800, there set a cleaning sprayer at the air exhaust exit and hot air mouth, which can be rotated in automatic and full direction, without dead corner more convenient to clean.

4,Select the imported spray gun. It's convenient to operate and easy to master and flexible controlled technological requirement. The spray gun head requirement must keep in the range of 0.29 MPa to 0.39 Mpa.

5,Angle and sector can be adjustable , uniform density and particle in spray pressure and 0.4-0.5Mpa in atomization pressure that avoid the dropping leakage and blockage phenomenon of size, uniform atomization and large spray area, practical to adjust flow, free leakage and blockage, angle and sector.

6,Film coating machine contains the mechanical device of cauldron wrapping little material can coat at least 20kg plain pills in 150 type coating machine, regulate through it inherent machinery, make a small mount of medium coat in cauldron and will not cause the wasted of dressing and greatly improve the scope of appliance

Picture of complete set of film machine:

Scheme of woring :

Coated sample:

Technical parameters:

Item/model | BG150D | BG80D | BG40D | BG10D | BG5D | |

Load capacity | 150kg | 80kg | 40kg | 10kg | 5kg | |

Revolutions (r/min) | 1-16RPM | 1-19RPM | 1-21RPM | 1-25RPM | 0-21RPM | |

Machine power | 2.2KW | 1.5KW | 1.1KW | 0.55KW | 0.37KW | |

Diameter of coating drum | 1200mm | 930mm | 780mm | 500mm | 564mm | |

Power of air exhaust cabinetmotor | 5.5kw | 3kw | 2.2kw | 0.75kw | 0.55kw | |

Air exhaust flow | 7419 m3/h | 5268 m3/h | 3517 m3/h | 1285 m3/h | 805 m3/h | |

Power of hot air cabinet motor | 1.5kw | 1.1kw | 0.75kw | 0.37kw | 0.25kw | |

Hot air flow | 2356 m3/h | 1685 m3/h | 1285 m3/h | 816 m3/h | 504 m3/h | |

Weight of main machine | 850kg | 600kg | 500kg | 200kg | 750kg | |

Air consumption | Pressure | ≥0.4Mpa | ≥0.4Mpa | ≥0.4Mpa | ≥0.4Mpa | ≥0.4Mpa |

Air consumption | 0.7 m3/min | 0.35 m3/min | 0.2 m3/min | 0.2 m3/min | 0.2 m3/min | |

In seaworth wooden case

45 working days

We ,Huizhou Pingfang pharmaceutical machinery co. ltd. is a professional manufacturer and supplier for pharmaceutical machinery, pharmaceutical packing material company, who is standing firmly with a good reputation in the industry of China pharmaceutical machinery.

Our company focus on fabricating efficient and technically sound pharmaceutical machines that meets or exceed our customer’ expectations. Our vast product selection caters to numerous industries, worldwide. We are specializing in machinery including, pulverizes, mix, Granulate, tablet press machine, coating machine, soft capsules filling machine, hard capsules filling machine, ampoule filling and sealing machine, oral liquid filling production line, syrup machine, eyes drop filling machine, lyophilized powder production line, injectable vial powder filling production line, Ointment machine, Suppository machine, spray filling machine, pharmaceutical testing and experiment instrument, traditional Chinese medicine machine and packing materials. The packing materials including pharmaceutical PVC, PTP aluminum film, hard aluminum, vial, stopper, aluminum stopper, ampoule, glass, capsule, packing strap of suppository physic. Meanwhile, we can undertake turn key projects for conceptual design, process design, water treatment solutions, clean-room design, etc.

Because we stick to offer the high quality and competitive price to our customer, our machines have been exported many countries of world such as Singapore, Vietnam, Malaysia, Thailand , Bangladesh, USA, Russia, Pakistan, Nigeria, Chile, Germany, Denmark, Bolivia, Peru, Mexico, South Africa, Iran, Argentina, Canada, Australia, India, Kazakhstan, Turkey, Egypt, Brazil, Syria, Yemen and more. In order to offer the best quality, we manufacture our products in accordance with international standards, such as FDA, GMP, CGMP. We also be approved by CE, ISO certificate.

To be statification with you, We can provide with professional technical support if you are in question of fix or installation the machines at customer bill account. Also, we can send our technical solution on video line at any time just you call or computer.

-What's capacity can do at a batch?

Answer: we can do it as per your required, 40kg, 80kg,150kg as required.

-What Quality of machine it is?

Answer: it's acording to GMP and ISO quality standard production

-What's the manufacturing date?

Answer: it will be 45 working days after confirmed deposit by TT

-

BYC-600 sugar coating machine is used for sugar coating of tablets and pills in the food industry

-

Nut/Chocolate/Almond Peanut Candy Coating Pan Machine Nut Icing Machine

-

Hot Sale Stainless Steel Small Pill Candy Sugar Diaphragm Coating Machine

-

BYC 800 sugar coating machine, tablet and pill coating machine, sugar coating machine

-

Commercial Fondant Sugar Coating Machine Almond Nut Peanut Solution Coating Machine

-

Hot Sale All Stainless Steel Tablet Film Coating Equipment Sugar Coating Machine

-

Laboratory Tablet Coating Machine Pharmaceutical Equipment

-

Food Small Automatic Nut Candy Candy Chocolate Peanut Almond Candy Tablets Nano Film Coating Pot Machine Coating Machine

-

Polishing machine Peanut tablet coating machine

-

Small candy nut icing pan machine

Other Products

-

$1800.00 - $2000.00 / unit

$1800.00 - $2000.00 / unit -

$1500.00 / set

$1500.00 / set -

$2600.00 / unit

$2600.00 / unit -

$10000.00 / unit

$10000.00 / unit -

$2000.00 / set

$2000.00 / set