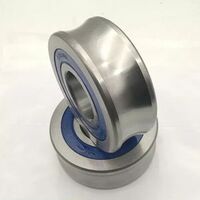

High Quality Low Speed gearbox belt conveyor system NF Backstop

-

Supplier: Qingdao Autos Ball Bearing Co., Ltd. -

Region: Shandong, China -

Contact: Mr Andy Lee -

Price: $10.65 / >=9 pieces -

Min. Order: 9 pieces

| Cage: | Nylon Brass; | Package Type: | plastic bags, carton, wooden case as per customers' request; |

| Bore Size: | 1 - 100 mm; | Size: | 19*42*24.6*12 Mm; |

| Payment: | T/T,L/C, Western Union; | Brand Name: | OEM; |

| Package: | Single Box; | Selling Units: | Single item; |

| Precision Rating: | ABEC-1; | Place of Origin: | Shandong China; |

| Package Preview: | https://sc01.alicdn.com/kf/HTB15g2Ef8TH8KJjy0Fiq6ARsXXar.jpg_640x640.jpg,https://sc01.alicdn.com/kf/HTB1Z0DMfZbI8KJjy1zdq6ze1VXaw.jpg_640x640.jpg; | Outside Diameter: | 1 - 100 mm; |

| Key Words: | conveyor system NF Backstop; | Delivery Detail: | 35 days after payment; |

| Single volume: | 25 cm; | OEM: | Availiable; |

| Single gross weight: | 10 KG; | Type: | Other Type; |

| Model Number: | SFR144X-ZZ#7MCM5P25LY75; | Application: | Automobile; |

| Material: | GCr15; | Product name: | High Quality Low Speed gearbox belt conveyor system NF Backstop; |

| Certificate: | ISO9001:2008; | Seals Type: | Sealed; |

High Quality Low Speed gearbox belt conveyor system NF Backstop

NYD NF RSBW AV FRHD Sprag Freewheel Backstop Clutch

Features of backstop for conveyor

ND NJ NYD backstop is kind of low - speed plugging device, its structure is compact, light weight, reliabale wedge, relif operation without binding, installer.

It is primarily apply to belt conveyor, bucket lift helicopters, etc.

Parameter of backstop for conveyor

| Torque Capacity (N·m) | Max Rotation Speed | ID | OD | Length | ||

| Model | Inner race r/min | Outer race r/min | H7 (mm) | h7(mm) | (mm) | |

| NYD 95 | 8000 | 150 | 0 | 80~95 | 230 | 110 |

| NYD 110 | 11000 | 150 | 0 | 90~110 | 270 | 110 |

| NYD 135 | 16000 | 100 | 0 | 100~130 | 320 | 130 |

| NYD 160 | 25000 | 100 | 0 | 120~160 | 360 | 140 |

| NYD 200 | 38000 | 100 | 0 | 160~200 | 430 | 160 |

| NYD 220 | 50000 | 80 | 0 | 160~220 | 500 | 230 |

| NYD 250 | 90000 | 50 | 0 | 180~250 | 600 | 290 |

| NYD 270 | 125000 | 50 | 0 | 200~270 | 650 | 290 |

| NYD 300 | 180000 | 50 | 0 | 230~300 | 780 | 290 |

| NYD 320 | 270000 | 50 | 0 | 250~320 | 850 | 320 |

| NYD 350 | 320000 | 50 | 0 | 250~350 | 930 | 360 |

| NYD 425 | 520000 | 50 | 0 | 320~420 | 1030 | 450 |

| NYD 450 | 700000 | 50 | 0 | 350~450 | 1090 | 480 |

Installation and Maintenance

1.NYD Backstop mainly used to prevent conveyor or pump running reversely in low-speed .

2.Before installation, be sure the inner race rotation direction ( direction of arrow marked on the inner race) conforms to the conveyor belt rotation direction.

3.Install the torque arm of backstop tightly by using a 11T or higher grade bolt. Please be sure torque arm surface is aligned with the side of outer race and free from any dust.

4.Recommended shaft tolerance is h7 or h8.

5.When mounting the clutch onto the shaft, apply pressure to the outer race only. Do not use a hammer to beat inner race, outer race ,or dust cap directly. No any force put to the dustproof end plate .

6.Use only a parallel key to secure the clutch to the shaft. Do not use a tapered Key.

7.When mounting NYD160 or larger size clutch ( Grease lubrication type),place one of the two oil holes at the bottom. It is convenient to discharge the grease and clean the clutch.

8.When shaft rotates, the end of the torque arm would move to some direction. Limiting the torque arm only in the rotation direction, but be sure there is some space for torque arm to rotate freely. The inside clutch would be warped if torque end is fixed completely. And it would damage the elements .

9.The backstop clutch torque arm is standard ones.

Lubrication

NYD95-135 are delivered with grease, no need more maintenance; NYD160-450 use oil lubrication, need to be changed every two years. When adding oil, loosen the outer race rings, open the bottom oil hole bolt, let the oil out, then add oil by ring hole.

According to the buyer requests for packaging

-

NUKR 62 for Tracker

-

Japanese IKO cam follower bearing CFS6 CFS6V roller bearing 6x12x9.5mm

-

Sprag type one way bearing DC5476B DC5476B(4C) overrunning clutch bearing 54.765x71.425x16mm

-

China Factory Water Pump Bearing WB1630073 885152 WB Series Water Pump Shaft Bearing

-

High Precision Micro Synthetic Double Cup Sapphire Ring Gasket Ball Ruby Nozzle Ball Watch Compass Gemstone Bearing

-

Factory direct bearing BT2-0026 heavy duty truck hub bearing BT2-0026 93.8x148x135.5mm

-

Automobile water pump bearing WB1730080

-

RSCI20 One-way Overdrive Clutch with Freewheel Bearings

-

water pump bearing 885141 885144 885147 885151B 885154

-

AL35 ALP35 High Quality Roller One Way Bearing Clutch

Other Products

-

$1.00 - $5.00 / piece

$1.00 - $5.00 / piece -

$1.00 - $5.00 / piece

$1.00 - $5.00 / piece -

$5.00 / piece

$5.00 / piece -

$2.00 / piece

$2.00 / piece -

$5.00 / piece

$5.00 / piece -

$2.00 / piece

$2.00 / piece -

$0.01 / piece

$0.01 / piece -

$1.99 / piece

$1.99 / piece -

$0.10 / piece

$0.10 / piece -

$3.40 / piece

$3.40 / piece