Commercial Used Stainless Steel 304 Small Scale Frozen French Fries Making Machine Potato Chips Production Line

-

Supplier: Henan Gelgoog Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Lily Feng -

Price: $1500.00 /set -

Min. Order: 1 set

| Key Words: | Frozen French Fries Production Line; | Machine Material: | SUS304; |

| Output product name: | French Fries/Potato Chips; | Weight: | 480Kg; |

| Packaging Detail: | Frozen Potato Production Line with Wooden Packing As Export Standard; | Place of Origin: | Henan China; |

| Raw material: | Fruit,Vegetables; | Raw Material: | Fresh Potatoes; |

| Dimension(L*W*H): | 48m*3m*5m; | Brand Name: | GELGOOG; |

| Applicable Industries: | Manufacturing Plant,Food & Beverage Factory,Food Shop,Food & Beverage Shops; | Application fields: | Vegetable processing plant,Fruit processing plant,Snack food factory,Frozen food Factory; |

| Features: | High Automation,Flow Production; | Supply Ability: | 100 Set/Sets per Month; |

| Power(W): | 54Kw; | Payment Terms: | L/C,T/T,Western Union,Trade Assurance; |

| Certification: | CE ISO; | Warranty: | 1 Year; |

| After-sales Service Provided: | Field installation, commissioning and training; | Workers: | 4-6 workers; |

| Port: | Any Port of CHINA; | Machinery Function: | Making French Fries; |

| Voltage: | 380V; |

Automatic Frozen French Fries Potato Chips Production Line

Automatic Frozen French Fries production line is used for making french fries, with capacity from 70-2000 kg/h for selection. By changing some machines, can be used for making slices potato chips.

Frozen fries have become one of most popular snacks for consumers because of fast, simple and delicious features. They are also fast-food snacks in fast-frozen foods. Want more information about French fries production line, just feel free to contact us.

Frozen French Fries Production Line Production Process

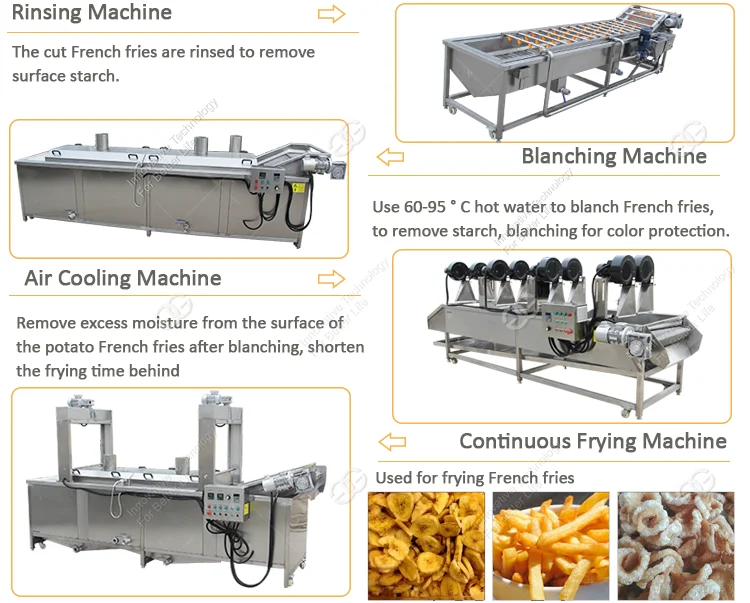

The cleaned and peeled fresh potatoes pass through picking line and enter french fries cutting machine. The size can be adjusted according to customer requirements. The starch on the surface of the potato French fries is removed by the blanching line while keeping the color of the potato French fries so that it does not black.

After blanching, the air line can effectively remove the moisture on potato french fries surface and then enter French fries frying line. The frozen fries are fried for a short time, then cooled by air-cooled oil, and then enter the quick-freezer and packaging machine.

Frozen French Fries Potato Chips Production Line Main Equipment

Potato washing and peeling machine, potato cutting machine, blanching Machine, dewatering machine, french fries frying machine, deoiling machine, flavoring machine, freezing machine, and packing machine.

-

Fully automatic potato chip production line frozen potato chips making machine

-

Factory Price Potato Chips Production Line Fresh French Fries Making Machine Potato Chips Processing Factory

-

HORUS High Quality Automatic Potato Chips Making Machine Potato Shredded Machine

-

Fully Automatic Frozen French Fries French Fries Making Machine Production Line For Sale

-

Tornado manual potato machine made of stainless steel

-

Industrial 300-1000kg/hour Fully Automatic Potato Chips Production Line/Potato Chips Making Machine

-

French fries production line 1/4 Frozen machine

-

400kg/h Automatic Frozen French Fries Production Line Price

-

Potato Chips Production Line Vacuum Frying Potato Chips Maker Batch Fryer

-

High Quality Pringles French Fries French Fries Processing Equipment Potato Chips Production Line Manufacturing Machine Price

Other Products

-

$11000.00 / set

$11000.00 / set -

$14900.00 - $15000.00 / set

$14900.00 - $15000.00 / set -

$3900.00 - $4000.00 / set

$3900.00 - $4000.00 / set -

$6000.00 / set

$6000.00 / set -

$3000.00 / set

$3000.00 / set -

$60000.00 / set

$60000.00 / set -

$4000.00 / set

$4000.00 / set -

$12000.00 / set

$12000.00 / set -

$3000.00 / set

$3000.00 / set -

$2000.00 / set

$2000.00 / set