Pneumatic desktop metal engraving machine for metal marking

-

Supplier: Jiansu Kuntai Industrial Equipment Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Jenny Lau -

Price: $550.00 /set -

Min. Order: 1 set

| Marking area (mm): | 125mmx85mm/150mm x 130mm/200mm x150mm/300mm x 200mm); | Place of Origin: | Jiangsu China; |

| Dimensions: | 43cm x 30cm x 75cm; | Brand Name: | Kunai; |

| Condition: | New; | Inputting air pressure: | 0.3~0.6MPa; |

| Marking speed: | 30~40mm/s; | Selling Units: | Single item; |

| Weight: | 36kg; | Warranty: | 1 Year; |

| Material hard request: | below HRA60; | Power supply: | AC220V±10%50Hz; |

| Certification: | CE,ISO9001; | Rated Power: | 500W; |

| Package Type: | Carton outpackage:84cm x 53cm x 51cm/set Weight:37kg/set; | Single package size: | 42X47X83 cm; |

| Engraving Speed: | 30mm~40mm; | Applicable Industries: | Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Retail,Construction works ,Energy & Mining; |

| Milling Cutter Diameter: | 2mm/3mm/4mm; | Single gross weight: | 37 KG; |

| After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; | Whole machine power: | 500W; |

| Marking depth: | 0.01~2mm (depends on the different materials); | Main Axle Rotational Speed: | 300; |

| Feeding Height: | 300mm; | Application: | 120mm x 80mm/300 x 200; |

| Application: | Small metal marking; | Up and down lifting height: | 0~300mm; |

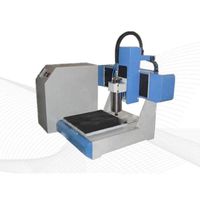

Pneumatic desktop metal engraving machine for small metal marking

Basic principles

Computer controls marking-needle to move on traces of pre-edited characters and graphs, meanwhile, to strike materials at a high frequency under the application of compressed air, thereby, to form needed characters and graphs.

Major functions

The marking machine can print any graphics and English characters in a variety of materials, parts, also can adjust the character size, auto-marking date and the water code, VIN code. The machine can be internet communication;

Application:

Suitable for all kinds of metal or non-metal sign round automatically marking, round marking of parts, as well as radial cylindrical workpiece marker.

Particularly applicable to various nameplates, plate marking, using a simple convenient and economical

Machine characteristics:

1.Working table is precision die casting,

2.128 sub-drive

3. Imported straight line guide rail,

4.High-precision stepping motor,

5.Adopt the imported tungsten alloy print pin, stable and long life.

6.Advanced USB interface control technology

7.High performance industrial motherboard, the needle work automatically.

8.Effective anti-jamming, radiation-resistant, adaptable for harsh environment.

9. Rigid column, high accuracy, Low running costs and virtually no consumable costs. Production

Technical Specification

Marking speed | 30~40mm/s |

Marking depth | 0.01~2mm (depends on the different materials) |

Marking contents | characters, alphanumeric, date, numbers, serial NO,VIN code etc. |

Marking area (mm) | 125mmx85mm/150mm x 130mm/200mm x150mm/300mm x 200mm(customized support ) |

Up and down lifting height | 0—300mm |

Materials request | below HRC60 metallic and nonmetallic materials (above HRC60 need special stylus) |

Whole machine power | 200W |

Work power | AC100V~220V±10%50Hz |

Inputting air pressure | 0.3—0.6MPa |

Fixture weight bear | Within 10kg |

Product photos

Marking sample view:

Factory view:

Professional production line guarantee the product high quality and good efficient.

Certificate:

ISO9001:2008 Quality Management System Certificate

CE certificate

Package:

Plywood case package,keep safe delivery.

Accessories:

Return & Feedbacks

- We can provide the main component for each marking machine, because we do not have the maintenance department at overseas . You can send back the problem spare parts to maintenance or replacement the new spare parts for your marker.

- We depend on our domestic reputation and customer satisfaction to succeed. Therefore, your feedback is extremely important to us.

After sales service:

1.One year for free warranty (include whole machine and parts, the material except) |

2.We can supply the new machine parts or fix the old one. |

3.Free design and guide for customer |

4.Free software update |

5.Professional technical support |

Contact us:

-

Voiern 20w 30w 50w 100w ring engraving machine and metal fiber laser marking machine with MAX JPT RAYCUS laser source

-

Pneumatic dot peen marking machine Eetal nameplate engraving machine metal serial number engraving machine

-

2022 New Mini Portable Laser Engraver Cutting Machine For Wood Leather Plastic Engraving OEM Logo Brand

-

Dot peen marking machine cylinder material dot peen marking machine nameplate dot peen marking machine

-

Fully automatic portable electric mini dot peen marking machine

-

Small CNC Metal Medal Making Machine Price

-

Mini 3030 4040 desktop cnc engraving machine engraving and milling machine

-

Automatic Portable Electric Mini Pointing Needle Marking Machine High Quality Pneumatic Marking Machine

-

Desktop point needle automatic metal CNC engraving machine metal

-

small size vin number SC-25*90 handheld dot peen chassis marking machine

Other Products

-

$500.00 / set

$500.00 / set -

$440.00 / set

$440.00 / set