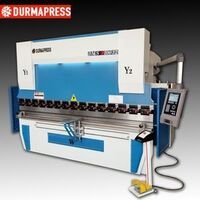

China NC hydraulic plate angle bender, press brake price

-

Supplier: Maanshan Durmapress Machinery Technology Co., Ltd. -

Region: Anhui, China -

Contact: Ms Kelly Durmapress -

Price: $15600.00 /set -

Min. Order: 1 set

| After-sales Service Provided: | Engineers available to service machinery overseas; | Price: | competitive; |

| Condition: | New; | Motor Power (kw): | 11; |

| Warranty: | 5 years; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,No after-sales service,Video technical support,Online support; |

| Raw Material: | Sheet / Plate Rolling; | Color: | red, white , blue ,optional; |

| Brand Name: | Durmapress; | Length of Working Table (mm): | 3200; |

| Material / Metal Processed: | Aluminum; | Material / Metal Processed: | Stainless Steel; |

| Key Selling Points: | Multifunctional; | Nominal Pressure (kN): | 1200; |

| Year: | 2017; | Port: | shanghai; |

| Certification: | ce; | Machine Type: | Torsion Bar; |

| Warranty: | 5 Years; | Automatic Level: | Semi-automatic; |

| Certification: | ISO 9001:2000; | Automation: | Automatic; |

| Place of Origin: | Anhui China; | Machine Type: | Press Brake; |

| Weight (KG): | 6800; | name: | hydraulic cnc press brake; |

| Packaging Detail: | Seaworthy packaging for Steel bending machine price, steel bar cutting and bending machine for sale; | Payment Terms: | L/C,T/T,Western Union; |

| Extra Services: | End Forming; | Automation: | Automatic; |

| Applicable Industries: | Machinery Repair Shops; | Supply Ability: | 1000 Set/Sets per Year; |

| Width of Working Table (mm): | 350; |

Technical parameter

| NO | Item | Value | Unit |

| 1 | Nominal force | 1000 | KN |

| 2 | Worktable length | 3200 | mm |

| 3 | Worktable height | 850 | mm |

| 4 | Slider stroke | 100 | mm |

| 5 | Max opening height | 320 | mm |

| 6 | Slider stroke adjustment | 75 | mm |

| 7 | Distance between columns | 2600 | mm |

| 8 | Throat depth | 320 | mm |

| 9 | Slider speed | V-working:9 V-return: 45 V-unload: 50 | mm/s |

| 10 | Main motor | Y160M-6 n=960r.p.m N=7.5KW | |

| 11 | Oil pump | 25MCY14-1B q=25ml/r p=31.5Mpa | |

| 12 | System max pressure | 25 | Mpa |

| 13 | Dimension | 3200×1600×2450 | mm |

Main feature

1. The frame is steel structure, left and right vertical plate, table and pressure plate welded into a unitary structure, after welding to eliminate internal stress by tempering, exceptional rigidity, high stability.

2. Important parts of the frame, sliders, etc. are used ANSYS finite element analysis software to ensure machine reliability.

3. Hydraulic drive, cylinder on both end of machine, disposed on the slider to drive it work directly.

4. Torsion axis synchronization for slide synchronous mechanism.

5. Adopt a mechanical stopper mechanism, stable and reliable.

6. Back Gauge size and slide stroke controlled by CNC system, back gauge with high precision ball screw, stable operation and precise positioning.

7. The CNC system adopts frequency conversion control technology, with multi-step

programming function, simple and easy to operate.

8. Inclined wedge deflection on the compensation mechanism, in order to guarantee access to high bending accuracy

9. Safety barrier device all around the machinery, electrical cabinets equipped with Open door cut-off function, emergency stop button around front and back, protective cover foot switch to ensure safe working.

1. Special numeric-control system is fitted with mainframe of the bending machine.

2. Multi-work-step programming function is able to achieve an automatic operation and continuous positioning of multi-step procures, as well as an automatic precision adjustment for positions of rear stopper and gliding block.

3. The machine is provided with bend counting function, for a real-time display of processing quantity and power failure memory of positions of stopper and gliding block, as well as procedures and parameters.

4. Imported ball bearing lead screw and linear guide rail are used for rear stopper, to ensure the positioning precision of rear stopper, for processing precision of machine to be higher.

-

Manual or pneumatic table stainless steel sheet metal / sheet metal bending machine / plate bending machine

-

DAMA TP10 Hydraulic Press Brake Large Heavy Duty CNC Controller Hot Selling Press Brake

-

CAC-75W hydraulic angle steel bending machine

-

AH Press Brakes for (Manual, Hydraulic, NC Hydraulic, Manual Folding Machine, Power)

-

2022 European high standard low cost MB8 series 200Tons/3200 CNC bending machine for sale

-

3KW Plate Bending Machine Hydraulic Multifunctional Steel Plate Bending Machine

-

Manual Sheet Bending Machine Hydraulic Bending Machine Metal Bending Machine

-

(W1.0X610B, W1.0X915B, W1.5X1220Z ) small handbrake/disc & box brake with CE, best price

-

Tool molds on bending machines, press blades on bending machines

-

Hot selling hydraulic new bending machine sheet metal bending machine 80t 3000 4000 6000

Other Products

-

$5999.00 - $6999.00 / set

$5999.00 - $6999.00 / set -

$5800.00 - $7800.00 / set

$5800.00 - $7800.00 / set -

$5600.00 / set

$5600.00 / set -

$11200.00 / set

$11200.00 / set