Full Auto Vacuum Forming Machine for food container, egg trays, blister, cup lid

-

Supplier: Shanghai First Vacuum Machine Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Mandy Tang -

Price: $70000.00 /set -

Min. Order: 1 set

| Dimension(L*W*H): | 8000*1800*2200 mm; | Power(W): | 80KW; |

| Brand Name: | First; | Place of Origin: | Shanghai China; |

| Product Type: | Fast Food Box; | Weight: | 4000kgs; |

| Type: | Vacuum Forming Machine; | Supply Ability: | 3 Set/Sets per Month; |

| Port: | Shanghai; | Condition: | New; |

| Certification: | CE Certificate; | Payment Terms: | L/C,T/T,Western Union,MoneyGram; |

| Certificate: | CE, ISO9001:2008; | Packaging Detail: | Export Worthy Packaging, loaded in 40HQ; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Plastic Type: | PP, PS, PET; |

| Voltage: | 380V 50HZ or customized; | Automatic: | Yes; |

Positive & Negative Pressure Full-Auto Vacuum Forming Machine

Model: LS-610

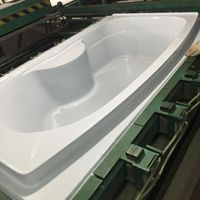

Machine reference photo:

Application:

The material such as PP, PE, PS, PVC, PET, PETG, EPS, HIPS, HDPE, PMMA in soft film could be processed by this machine, it is an ideal vacuum forming machine for blisters, clamshell, plastic containers, fruit trays, egg trays, dishes, bowls, lids, medical packaging such as ampoule trays and vial trays, etc.

Product Introduction:

Basic units:

1. PLC control system with touch screen

2. Independently controllable heating zones

3. Automatic cooling system with industrial chiller and spray guns

4. Automatic vacuum forming system

5. Steel components coated with polyurethane

6. Far infrared ceramic heating bricks

Main feature:

1. This machine adopts the latest international plastic sheet molding technology and crafts, with the design of mechanical electrical integration, using PLC control, the whole system realizes the HMI (human machine interface).

2. It is suitable for male mold and female mold forming, which adopts the integration of positive and negative air pressure to ensure good molding quality and precise molding size.

3. There are four processing parts: forming, cutting, stacking & counting, which are simultaneously completed, greatly increased the production speed.

4. High speed, low noise, high reliability and convenient to maintenance.

5. Feeding, cutting & stacking adopt servo motor control, high speed, accurate and stable.

6. Forming, punching and cutting by the system of hydraulic drive, automatic oiling, eliminate unnecessary trouble and pollution of the product.

7. Tool change system of optimized ergonomic design which shortens the time for tool change.

8. Two-stage vacuum, double times on mould, vacuum-delay.

9. This machine consist of Heating system, Forming system, Vacuum system, Pneumatic system, Cooling system and Control system.

10. The heating box temperature control system adopts full computerize intelligent automatic compensation controlling, heating brick adopts digital input, has a high precision fine-tuning, uniform temperature, fast temperature elevation (only 3 minutes from 0~400℃), stability (not influenced by external voltage, temperature fluctuation is less than 1℃). Low energy consumption (energy saving about 15%), heating box service life is long, etc.

11. Heating system: Far infrared ceramic heating bricks with independent control system, each ceramic heating brick is controlled via PLC integration control on touch screen to ensure the sheet is heated uniformly over its entire surface area and throughout its thickness. Adopts fully enclosed furnace to reduce heat loss.

12. Cooling system equipped with air-cooled industrial chiller, spray gun and circulating water cooling chassis, make the forming speed faster and guarantee the molding quality.

13. Apply air pressure to release the molding from the mold, damage of the molding in the releasing process is avoided.

14. Two-stage vacuum sucking to ensure the thick sheet is easy to form and to improve the molding quality.

15. Machine cycle status is clearly visible at a glance and all parameters can be adjusted in real time without interrupting the current cycle.

16. The PLC program offers saved memory for project to project recognition, that means when processing the same project in next time, there is no need to set the operating parameters again, just touch the project name or project number.

17. Imported electrical and pneumatic components from International well-know manufacturer make the machine features reliable quality and wearing well.

18. Special chain rail, no deviation and vibration, wearing well.

Main technical parameters:

Model | LS-610 |

Applicable material | PP, PE, PS, PVC, PET, PETG, EPS, HIPS, HDPE, PMMA |

Max forming size | 610×660 mm |

Max forming height/depth | 120 mm |

Max roll sheet diameter | Φ600mm |

Sheet width | 470~670 mm |

Thickness of sheet | 0.15~2.0 mm |

Stroke of top mold | 120 mm |

Stroke of bottom mold | 120 mm |

Max cutting force | 60 Tons |

Power supply | 3P 380V AC 50/60Hz or customize |

Top heater power | 32KW |

Bottom heater power | 32KW |

Max power consumption | 80KW |

Air pressure | 0.8 Mpa |

Working speed | 10~18 cycle/min |

Overall size (L×W×H) | 8000×1800×2200 mm |

Weight | 4000KG |

Remark: We can provide customized machine according to user’s requirement. Considering the development of machine, all data and pics is for reference only | |

Layout drawings:

Products reference photo:

Factory photo:

-

Disposable Foam Plate Production Line/Vacuum Forming Lunch Box Making Machine/Fast Food Foam Plate Production Machine

-

Low Price New Plastic Vacuum Forming Machine to Make Disposable Plates/Foam Tableware/Food Containers

-

Used cup machine for vacuum plastic forming

-

Acrylic Forming/Making/Vacuum Tub Forming Machine

-

Durable desktop acrylic pvc plastic vacuum forming machine

-

PS Expanded Styrofoam Pan Container Pan Tray Food Box Small Production Machine, Ellie Whats 008613780912769

-

FUSHI brand PS EPS thermocol foam board container tray mould machine

-

small mini desktop acrylic pvc plastic vacuum forming machine/thermal vacuum forming machine

-

best price vacuum forming machine

-

BSX2030 Super Discount High Modular Acrylic ABS PP Thermoforming Deep Vacuum Forming Machine