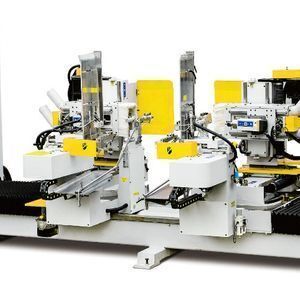

MXS2000B professional design CNC double end tenoner wood furniture new woodworking machine

-

Supplier: Foshan Saga Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Jack Shi -

Price: $28285.60 /set -

Min. Order: 1 set

| Dimension(L*W*H): | 4200mm*1800mm*1750mm; | Key words: | tenoner woodworking machine; |

| Power(W): | 14.55kw/19.75kw; | Weight: | 2650kg; |

| Product name: | woodworking tenon mortising machine; | Warranty: | 1 Year; |

| Motor Speed: | 10000-18000r/min; | Name: | CNC tenon machine; |

| Motor: | 4.5*2; | Application: | wood process; |

| Payment Terms: | L/C,T/T; | After-sales Service Provided: | Free spare parts; |

| Application: | Solid wood furniture; | Place of Origin: | Guangdong China; |

| Automatic Grade: | Automatic; | Condition: | New; |

| Supply Ability: | 10 Set/Sets per Month; | Brand Name: | SAGA; |

| Packaging Detail: | Water proof plastic with plywood base, or closed plywood box; | Total power: | 14.55/19.75kw; |

| Size: | 4200*1800*1750mm; | Advantage: | High productivity; |

| Feature: | Easy opeation; | Port: | Guangzhou; |

Product Application

CNC double-end tenoners offer the ideal solution when it comes to the manufacture of furniture, doors, door panels, fronts, frame components, wall and celling panelling and follring elements.

Main Features

1. Longitudinal and transverse processing in one line;

2. Many different materials can be processed using the double-end tenoner;

3. Tongue and groove profiling of lamella;

4. Angle and/or bevel cuts;

5. High precision in the profiles to be used;

6. High level of repetition precision;

7. Short setup times;

8. Adapted tool hoods for optimal removal of shavings and reduction of energy costs.

Process Display

The two ends of the workpiece are processed simultaneously, thus greatly increasing the production capacity.

Machine Parts

With digital control and touch LCD screen, it is easy to operate and realize automatic tenoning operation.

Process Display

Suitable for square tenon, round tenon, vertical tenon and oblique tenon.

Machine Parts

The cutting tool feeding speed is controlled by servo system. The fastest speed of the cutting tool can reach 12000 r/min to ensure the smoothness of the workpiece.

Door Raised Panel Shaper Cutter

91.8% Response Rate

Brush and drum sander

91.8% Response Rate

Four side moulder

91.8% Response Rate

Single Spindle Machine

91.8% Response Rate

CNC Mortising Machine

91.8% Response Rate

Straight Line Rip Saw

91.8% Response Rate

20000 square meter showing room 365 days open at Lunjiao exhibition hall, which is the biggest and most specialized town for wood working machinery and accessaries, most of the member in this hall is Saga's partner.

Who is SAGA?

Saga is a union of several wood working machinery supplier, all those supplier got at least 15years of experience on their own field, we cooperate to offer right and economic solution for customer, customer just rely on one single source for both equipment and service, thus you will feel comfort and easy for any requirements. The good price enhance our sell and bring bulk production which makes our price more competitive, thus we share this benefit with you.

1.What is your price term and payment term?

We offer FOB, CIF, CNF EXW price, we accept TT/LC or other negotiate.

In stock: 100% payment;

Not in stock: 30-40% deposit for confirm the order, rest is paid before shipment, some customized machine may need 50% deposit

2.How long for delivery?

Some standard machine or commercial machine, always in stock, for high value machine or customized machine, may takes 30-40 days production.

3.After sale and warranty?

Most machine got 1 year warranty except some consumption spare, all spare within warranty period is free for change, in the condition that machine is running according to the manual book(saga got rights for explain).

4.Installation for complex machine.

We have 20 years of experience for installation all over the world for big and complex machine, customer response for food and living as well as transport, some area may be served by our agent. For commercial machine, we will do our best to offer installation guiding video.

5.Free spare parts for change

Most of our machine use international standard, especially electric spare parts, if not, we offer free spare parts to avoid any urgent condition to minimize risk of downtime.

6. Safety for the machine and packing

We have mature experience for sea transport packing, for some irregular shape machine, we will do special fix and tight on container to avoid any risk of any broken.

-

Wood double-end drilling machine Woodworking blind processing double-end tenoning machine

-

Vertical portable woodworking mortising machine, portable small mortising machine

-

Page opener auxiliary wooden door lock opener carpentry slotted door installation artifact hinge opener

-

1200W bench wood tenon chisel machine for woodworking

-

Woodworking mortise square eye small multifunctional lock wood tenoning machine

-

MS3840 Woodworking Woodworking Chisel Mortise and Tenon Machine Heavy Duty Mortise and Tenon Machine

-

MX3815C-K CNC mortise and tenon tenon tenon tenon tenon woodworking machinery woodworking milling machine

-

ZICAR mortise woodworking machine mortise and tenon machine horizontal single shaft woodworking mortise machine for sale

-

tenoning machine woodworking woodworking tenoning machine

-

Heavy door lock tenoning machine