Metal Stainless Steel Sheet MDF Board Wood Door Double Side PVC PU Roll Film Coating Laminating Machine Laminate Line

-

Supplier: Foshan Ji Li Jia Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Edward Zhou -

Price: $2000.00 /set -

Min. Order: 1 set

| Packaging Material: | Paper,Plastic,PVC, PE, etc.; | Certifacation: | ISO 9001, CE; |

| Application: | Steel, stainless steel coil/sheet, titanium and aluminium; | Film Shelf Quantity: | 2-6 shelves; |

| Color Select: | Optional; | Power Source: | Electricity; |

| Certification: | ISO 9001, CE; | Application: | Machinery & Hardware,Sheet, coil, stone slab, etc.; |

| Weight: | 700kg (1300mm semi-auto model); | Panel Width: | 200-2100mm; |

| Place of Origin: | Guangdong China; | Applicable Industries: | Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Construction works ,Energy & Mining,Advertising Company; |

| Packaging Type: | Film; | Driven Type: | Electric; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Online support,Video technical support; | Automatic Grade: | Automatic; |

| Port: | Shenzhen Port /Guangzhou Port; | Packaging Detail: | Standard packing, spray with the anti-rust paint oil and cover with the oil-face anti-rust paper, then package with transparent plastic film.; |

| Feeding Method: | Roller convey; | Supply Ability: | 1 Set/Sets per Week customer in factory acceptance available; |

| Brand Name: | Ji Li Jia; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Laminating Side: | One side or both sides; | Voltage: | 220V/380V (Optional); |

| Type: | Laminating Machine; | Automation: | Semi-Auto or Full-Auto; |

| Dimension(L*W*H): | Actual Size; | Condition: | New; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Paypal; | Warranty: | 1 Year; |

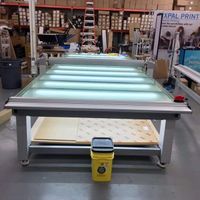

The laminating machines are designed to cover with a plastic film on a finished surface in order to protect it from dust, scratches and damages that can occur during handling and forming operations.

- JLTM semi-automatic laminating machine, user needs to cut the protective film manually, which is suitable for simple sheet-to-sheet lines and ideal for the highest efficiency coil-to-coil lines.

- AUTOTM automatic laminating machine, which compose the Ji Li Jia Automatic Blade™, This vertical-moving blade and an electronic positioning system to cut the PVC film between the two sheets, which can obtain a zero tolerance cutting effect. There has an integrated exhaust system (3,000m³/h) for film strip removal. This machine is especially useful in a fully automated sheet-to-sheet lines.

All JLTM /AUTOTM series laminating machines can be fully integrated with JDG /JSG or other series machine and also possible to install into an existing lines.

- Chromed steel roller for PVC protective film tension (standard) - Maximum 4 film holding reels are available (optional) - Pneumatic expansion shafts film holding reels with safety clamp (optional) - Long service life grease lubricated bearings - Photoelectric switch automatic positioning - Manual alignment correction of the film - Integrated safety systems - Automatic alignment of the film with the coil (only on JLTM coil version)) - By Using Ji Li Jia Automatic Blade™ technology to achieve zero tolerance cutting (only on AUTOTM) - Integrated exhaust system (3.000 0m³/h) for film strip removal (only on AUTOTM) - PLC control and human-machine dialogue touch screen (only on AUTOTM)

|

![]()

Model | JLTM | AUTOTM |

Cutting method | Manual | Automatic blade-cutting |

Application | Coils & sheets | Sheets |

Useful width | 200 - 400 - 700 - 800 - 1050 - 1300 - 1600 - 2100 mm | |

Thickness range | 0.3~3.0mm (standard), maximum 12.0mm (optional) | |

Feeding speed | 10-20min (adjustable) | 15~20min (adjustable) |

Feeding motor | 2.2kw | 1.5kw |

Film applicator roll | Φ150mm, covered with rubber | |

No. of top film reels | 2 as standard and up to 4 as option | |

Film roll diameter | Inner Φ74mm, and outer up to Φ350mm | |

Machine pass line | 960mm | |

|

Foshan Ji Li Jia Machinery Co., Ltd. is a hightech company specialized in the R&D, production, and marketing kinds of surface treatment machine and related products. We start in thisfield in1995, and already install machines more than 20 countries.

Our company currently has 70 employee, including 10 expects, technician, and 2 programmer engineers. We have a high quality raw materials and manufacturing accuracy control, in order to represent the highest standard of the surface treatment machine.

|

-

EC-650 Economical and practical electric semi-automatic cold laminating machine

-

High quality RFID chip card making machine

-

Fayon 1600DA 160cm Automatic High Speed Cold Laminator Roll Laminating Machine Cold Laminator

-

Hangzhou Befitter HT-650 650mm 25" Automatic Hot Foil Transfer Laminator

-

Cheap price large format fayon smart workbench 1325 flat laminator workbench flat laminating machine flat laminating machine

-

SWFM520C 485mm fast hydraulic manual paper feeding automatic cutting and laminating machine 0-25m/min

-

L0 Wide Format Smart FY916 Manual Cold Flat Laminator

-

Hot selling double-sided adjustable speed manual a2 a3 hot and cold laminating machine laminating machine price

-

Automatic roll laminator/Automatic roll laminating machine

-

L388 automatic roll to roll roller laminating machine with metal roller paper hot roll laminating machine for printing shop