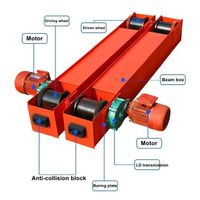

Paper mill handling overhead crane cranes parts with wire rope heavy duty high standard trolley

-

Supplier: Guangdong ShunFa Overhead Crane Equipment Co., Ltd. -

Region: Guangdong, China -

Contact: Mr. Shunfa Crane -

Price: $20000.00 /set -

Min. Order: 1 set

| Span: | Customized; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Wechat; |

| Port: | Foshan; | Max. Lifting Load: | Customized (3~160 ton); |

| Feature: | Bridge Crane; | Certification: | ISO 9002; |

| Packaging Detail: | Woodcase Standard Export Packing (Default). Flat rack and OT container shipping is offered upon request.; | Warranty: | 1 Year; |

| Brand Name: | Shunfa; | Working Class: | A1-A7; |

| Configuratoin: | Basic; | Condition: | New; |

| After-sales Service Provided: | Field maintenance and repair service; | Place of Origin: | Guangdong China; |

| Supply Ability: | 900 Set/Sets per Year; | Rated Lifting Moment: | Customized; |

| Max. Lifting Height: | Customized; |

Different Types of Overhead Crane Classifications

Determine Required Working Class

CLASS A, Standby or infrequent service

This service class covers cranes where precise handling of equipment at slow speeds with long idle periods between lifts are required. Capacity loads may be handled for the initial installation of equipment and for infrequent aintenance.

Typical examples: cranes used in powerhouses, public utilities, turbine rooms, motor rooms, and transformer stations. This is the lightest crane as far as the duty cycle is concerned.

CLASS B, Light service

This service class covers cranes where service requirements are light and the speed is slow. Loads may vary from no load to occasional full-rated loads with 2 to 5 lifts per hour, averaging 10 feet per lift.

Typical examples: cranes in repair shops, light assembly operations, service buildings, light warehousing, etc.

CLASS C, Moderate service

This service class covers cranes where service requirements are deemed moderate, handling loads which average 50 percent of the rated capacity with 5 to 10 lifts per hour, averaging 15 feet, with not over 50 percent of the lifts at rated capacity.

Typical examples: cranes used in machine shops, paper mill machine rooms, etc.

CLASS D, Heavy service

In this type of service, loads approaching 50 percent of the rated capacity will be handled constantly during the work period. High speeds are desirable for this type of service with 10 to 20 lifts per hour averaging 15 feet, with not over 65 percent of the lifts at rated capacity.

Typical examples: cranes used in heavy machine shops, foundries, fabricating plants, steel warehouses, container yards, lumber mills, etc., and standard duty bucket and magnet operations where heavy-duty production is required

CLASS E, Severe service

This type of service requires a crane capable of handling loads approaching the rated capacity throughout its life with 20 or more lifts per hour at or near the rated capacity.

Typical examples: magnet, bucket, magnet/bucket combination cranes for scrap yards, cement mills, lumber mills, fertilizer plants, container handling, etc.

CLASS F, Continuous severe service

In this type of service, the crane must be capable of handling loads, approaching rated capacity continuously under severe service conditions throughout its life.

Typical examples: custom-designed specialty cranes essential to performing the critical work tasks affecting the total production facility, providing the highest reliability with special attention to ease of maintenance features.

How we build your crane? Standard working procedure?

Crane Project Consulting

Professional team of experience crane engineers standby for your projects.

Crane Building

The largest crane manufacturing center in Foshan with 200+ workers.

Worldwide Crane Installation

We offer free installation and one year maintenance to our customers. A team of 80 support staff.

Factory

Welding Workshop

Our workshop is 200m in lenght.

Warehouse 1,5000 SQM

Team of Professionals

Our Team is partner of KONECRANES in Guangdong.

We check and inspect before delivery to our customers, offer different crane shipping solutions.

ANDRITZ

ANDRITZ is an international technology group providing plants, systems, equipment, and services for various industries. The company is one of the technology and global market leaders in the hydropower business, the pulp and paper industry, the metal working and steel industries, and in solid/liquid separation in the municipal and industrial segments.

APP China

Asia Pulp and Paper Group (APP) is responsible for delivering quality products to meet the growing global demand for tissue, packaging and paper. On any given day, our products find their way into the hands of consumers in various branded forms from all over the world.

Guangzhou Metro

The Guangzhou Metro is the rapid transit system of the city of Guangzhou in Guangdong Province of China. It is operated by the state-owned Guangzhou Metro Corporation and was the fourth metro system to be built in mainland China, after those of Beijing, Tianjin and Shanghai.

Q: Are you trading company or manufacturer ?

A: We are factory with a team of professional crane engineers.

Q: How long is your delivery time?

A: Generally it is 30-90 days from comfirmation of deposit. Addictionally lead time also depend on order quantity.

Q: Do you provide samples ? Is there free components?

A: Can not offer a crane sample. Yes, we offer some spare parts for free along with the first shipment or repeat orders.

Q: What is your terms of payment ?

A: Payment<=10000USD, 100% in advance. Payment>=10000USD, 30% T/T in advance ,balance before shippment.

Should you have any queries please contact our sales engineers.

-

Weihua customized double girder hook bridge crane 75 tons

-

The latest upgraded manual walking push crane system ergonomic walking trolley

-

Overhead Crane 5 Ton 10 Ton Double Girder Overhead Crane With Hoist Trolley For Sale

-

Popular Used QD Bridge Cranes

-

Made in China EOT crane end beam 2 tons 5 tons 7 tons 10 tons 16 tons bridge crane end beam

-

1 2 3 5 10 Ton Free Standing Modular Self Erecting Freestanding Overhead Crane with Steel Column Support Structural Frame

-

Electric Single Girder Overhead Crane 5t 10t 16t 20t 32t Light Overhead Crane

-

Best selling QB type double girder explosion-proof or explosion-proof or explosion-proof or explosion-proof electric bridge crane

-

Best selling light aerial bridge walking crane trolley system flexible combination bridge suspension electric double girder crane

-

Supply workstation Stable bridge crane system 500 kg 1 ton 2 ton 3 ton