Weihua customized double girder hook bridge crane 75 tons

-

Supplier: Henan Weihua Heavy Machinery Co., Ltd. -

Region: Henan, China -

Contact: Mr Jack Zhou -

Price: $9000.00 / 1 - 1 sets

$8000.00 / >=2 sets -

Min. Order: 1 set

Product details

| maximum. Lifting load: | 800 tons | color: | yellow or optional |

| Health status: | new | Pressure loss protection function: | include |

| payment terms: | L/C, Western Union, T/T, MoneyGram | Packaging details: | 1. Electrical components are packed in high-quality plywood boxes to reduce transportation deformation. 2. The main beam, end beam and electric hoist are packed with plastic woven cloth. It can reduce wear and tear during transportation. 3. If the size is too large, it is usually shipped in bulk or cut into containers. |

| emergency stop: | include | Polyurethane cushioning material: | include |

| Weight overload protection device: | include | feature: | Bridge crane |

| Core component warranty: | 1 year | port: | Any port in China, depends on customer inquiry |

| Applicable industries: | Building materials stores, farms, restaurants, construction machinery, general manufacturing, automobiles, foundries, pulp and paper | Turnkey projects: | can provide |

| Marketing type: | Hot Products of 2023 | Mechanical test report: | if |

| Supply capacity: | Annual output: 10,000 sets | Material: | Q235, Q345 carbon steel |

| Place of origin: | Henan, China | brand: | Weihua |

| span: | 34m or special design | product name: | Hook overhead crane |

| Showroom location: | Egypt, Vietnam, Philippines, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Thailand, Morocco, Kenya, Argentina, Colombia, Algeria, Sri Lanka, Bangladesh, South Africa, Kazakhstan, Kyrgyzstan, Uzbekistan, Tajikistan, Malaysia, Australia | Package preview: | |

| Warranty: | 1 year | painting: | 3 layers of anti-rust paint |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | Main electrical parts: | Siemens or Siemens brand |

| Video outbound inspection: | if | Rated lifting moment: | no limit |

| Weight (kg): | 25000kg | maximum. Lifting height: | other |

Product Description

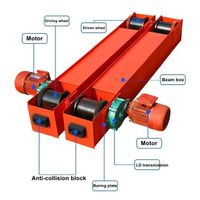

Double girder hook overhead crane

QD type double girder hook overhead craneIt consists of a beam frame, a crane traveling device, and a trolley with a lifting and moving device. The main beam is provided with rails for the movement of the trolley.

A mobile workbench is installed on the outside of the two main beams. One side is prepared to install and repair the crane mobile device, and the other side is prepared to install the trolley wire device.

There is a full-view cab suspended under the main beam. A joint console or a single control box is installed in the cab. A horizontal ladder is installed between the cab and the mobile platform. The main beam is connected to the slide frames on both sides with a joint point in the middle.

A mobile workbench is installed on the outside of the two main beams. One side is prepared to install and repair the crane mobile device, and the other side is prepared to install the trolley wire device.

There is a full-view cab suspended under the main beam. A joint console or a single control box is installed in the cab. A horizontal ladder is installed between the cab and the mobile platform. The main beam is connected to the slide frames on both sides with a joint point in the middle.

Contact us for more information!

Detailed pictures

Product parameters

Lifting capacity | time | 5 | 10 | 16/3.2 | 20/5 | 32/5 | 50/10 | ||||||||||

span | rice | 10.5-31.5 | |||||||||||||||

speed | main hook lifting | A5 | m/min | 11.3 | 8.5 | 7.9 | 7.2 | 7.5 | 5.9 | ||||||||

A6 | 15.6 | 13.3 | 13 | 12.3 | 9.5 | 7.8 | |||||||||||

Auxiliary. Hook lifting | 16.7 | 19.5 | 19.5 | 10.4 | |||||||||||||

Crab's journey | 37.2 | 43.8 | 44.6 | 44.6 | 42.4 | 38.5 | |||||||||||

tram running | A5 | 89.8/91.8 | 90.7/91.9/84.7 | 84.7/87.6 | 84.7/87.6 | 87/74.2 | 74.6 | ||||||||||

A6 | 92.7/93.7 | 115.6/116/112.5 | 112.5/101.4 | 112.5/101.4 | 101.4/101.8 | 75/76.6 | |||||||||||

Operating model | cabin; remote control; handle | ||||||||||||||||

Job responsibilities | A5,A6 | ||||||||||||||||

power supply | Three-phase AC 380V, 50Hz | ||||||||||||||||

VIEW MORE

You may like

-

The latest upgraded manual walking push crane system ergonomic walking trolley

-

Overhead Crane 5 Ton 10 Ton Double Girder Overhead Crane With Hoist Trolley For Sale

-

Popular Used QD Bridge Cranes

-

Made in China EOT crane end beam 2 tons 5 tons 7 tons 10 tons 16 tons bridge crane end beam

-

1 2 3 5 10 Ton Free Standing Modular Self Erecting Freestanding Overhead Crane with Steel Column Support Structural Frame

-

Electric Single Girder Overhead Crane 5t 10t 16t 20t 32t Light Overhead Crane

-

Best selling QB type double girder explosion-proof or explosion-proof or explosion-proof or explosion-proof electric bridge crane

-

Best selling light aerial bridge walking crane trolley system flexible combination bridge suspension electric double girder crane

-

Supply workstation Stable bridge crane system 500 kg 1 ton 2 ton 3 ton

-

Best price electric motor driven Eot crane end beam

Other Products

-

$20000.00 - $25000.00 / set

$20000.00 - $25000.00 / set -

$30000.00 / set

$30000.00 / set -

$1325.00 / set

$1325.00 / set -

$100000.00 / set

$100000.00 / set -

$30000.00 / set

$30000.00 / set -

$13000.00 / set

$13000.00 / set -

$13000.00 / set

$13000.00 / set