China eco-friendly dairy farm poultry manure cow dung dewatering machine solid liquid separator

-

Supplier: Xinxiang Chenwei Machinery Co., Ltd. -

Region: Henan, China -

Contact: Mr JASON DU -

Price: $2000.00 /set -

Min. Order: 1 set

| Type: | Liquid solid separating machine; | Main power: | 4KW-5.5KW; |

| Port: | Qingdao/Tianjin/Shanghai; | body material: | carbon steel/stainless steel; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Paypal; | Application: | Animal waste,food residue etc; |

| Place of Origin: | Henan China (Mainland); | usage: | reduce the moisture or water from materials; |

| Condition: | New; | Screen Diameter: | 200/280mm; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Pump power: | 3kw or 4kw; |

| Delivery Detail: | Shipped in 6 days after payment; | Brand Name: | Chenwei- solid liquid separator; |

| Machine name: | solid liquid separator; | Model Number: | CW-solid liquid separator; |

| Supply Ability: | 200 Set/Sets per Month solid liquid separator; | Handling capacity: | 7-20m3/h; |

| Certification: | ISO CE; | Packaging Detail: | The whole solid liquid separator will be packed in plywood case; |

| work principle: | screw extrusion; | Use: | reduce the moisture or water from materials; |

| Machine Category: | Other farm machines; |

China eco-friendly dairy farm poultry manure cow dung dewatering machine solid liquid separator

Function

This Cattle Farming Equipment is a solids-liquid separating machine including a screw conveyor. Using both principles of separation, by gravity and by mechanical pressing, the machine is designed to separate the liquid phase from the solid phase in a wide range of substances such as sludge, sewage, manure, solids-liquid mixtures, vegetables, processing waste and others, where the percentage of liquid inside the solid may be considerably different.

The separated solid and liquid phases can be handled in an easier and cheaper way. In some sectors this can even become a source of income.

Operation

The machine receives the material to be separated and conveys it using the screw conveyor inside the separator casing. The liquid phase is separated through the mesh of the cylindrical screen which encloses the screw conveyor. Along its path toward the exit, the material gradually separates progressively the less linked liquid and then the more strongly linked liquid until a plug of almost dry material has formed before the outlet. The plug is continuously expelled through the outlet diaphragm.The machine will automatically find its balance of squeezing force depending on the material. Consequently, it can be used for a wide range of materials without the need for any manual adjustments.

Performance & Technical Features - Benefits

Compliant with a wide range of materials in different throughput rates

Optimized feeding thanks to compensator tank

Outlet diaphragm for solids manufactured from anti-wear engineering polymer: cost saving in spare parts

Self-balanced pressure at the solids outlet: steady and safe operation

Simple operation and cost saving in spare parts

Continuous operation

Quick return on investment

The main technical parameters

Commodity | Mode | Motor power | Reduction box | Speed(r/s) | Voltage | Capacity(m3/h) | ||

Main engine | CWY-280 | 5.5kw | 5-43 | 33.7 | 380V | Cow dung | Pig manure | Poultry dung |

4-6 | 5-12 | 2-4 | ||||||

Water pump |

| 3kw |

| 1450 | 380 |

| ||

Parameters of Solid and liquid separator for slughterhouse waste

Model | Motor (KW) | Capacity | Water Consume when Cleaning | Cleaning frequency | Max cesspool depth | Feeding method |

200 | 4 | 10 m3/h | 0.1 m3 | Each 20-30 days | 3.5m | Hopper or pump |

280 | 5.5 | 20 m3/h | 0.1 m3 | Each 20-30 days | 3.5m | Hopper or pump |

|

|

These spare parts for free when you buy this machine:

Item | Detail |

Pump | 1 Unit,3KW |

Water pipe | Dia:10mm/13.5mm, 12 meters |

Water seal | Two Units |

Switch Box | One Unit |

The three models' capacity for different raw materials:

Raw Material | Capacity(Cubic meters)/Hour | ||

CWY-280 | CWY-200 |

| |

Cow dung sludge | 15-20 | 10-12 |

|

Pig dung sludge | 20-25 | 10-15 |

|

Chicken dung sludge | 6-8 | 3-4 | |

Slaughterhouse waste water | 20-25 | 10-15 |

|

Biogas waste | 10-15 | 7-9 |

|

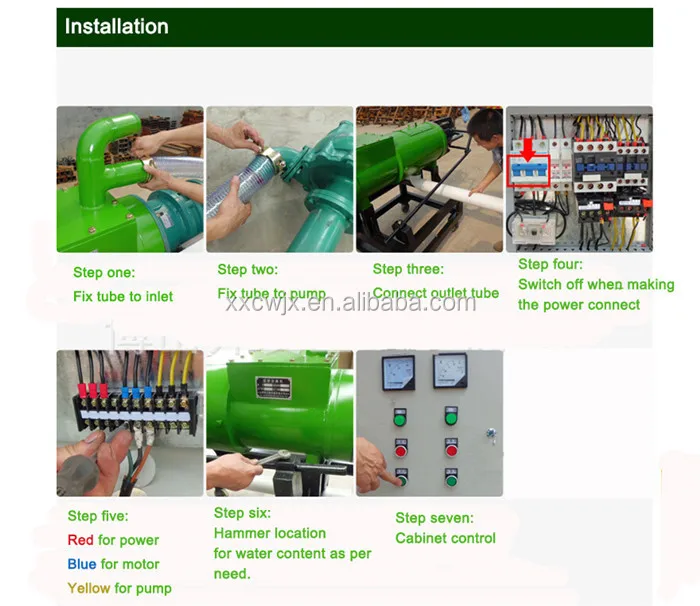

Installation:

Details solid liquid separator

Company information

FAQ

Q:What factors I need to get a quotation?

A: Material name,Water content,Your Desired output,Voltage & Frequency(Hz) is also needed for a precise quotation.

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Q: How do you ensure the quality of your product?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression for most of our customers at home or abroad.Skilled workers and strict quality control system can ensure every machine with best working performance.

Q: How do your after-sale service work if the product got damaged?

A: In the guarantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refound this part of cost.(note: Vulnerable parts do not include.)

Q: How could I trust your promise?

A: Firstly, you may check the assessment on our website certified by the appraisal agency Bureau Veritas;

secondly, we attend at least 4 to 6 international industry exhibitions held in China annually, like the Food Ingredients China, China International Battery Fair, CPhI, ICSE BioPh China, ICIF China, etc. We usually met our customers there for negotiation;

Thirdly, company inspection always available, if you have any representative or you would like to come to our site, we offer free shuttle from Zhengzhou airport to our company, welcome your visit.

-

Two-stroke four-stroke backpack side-mounted gasoline lawn mower weeder agricultural garden mower

-

Free Shipping!!!! HT550 Robot Lawn Mower / Lawn Mower Robot for Home Garden

-

TQS-350 STONER stone remover to clean sundries and impurities

-

Electric Small Household Lawn Mower Handheld Lithium Battery Garden Trimmer Rechargeable Lawn Mower

-

mealie brand sirloin

-

9YFSZ-2.2 Linear Square Bale Picking and Baling Machine

-

Hand push corn seeder for farm and garden

-

Manufacturer produces tractor mounted pasture harvester sickle mower cutting machine

-

small electric mixer for sale, mixer for mushroom substrates, spiral mixer prices

-

Tractor side mowers Sickle mowers

Other Products

-

$2500.00 / set

$2500.00 / set -

$999.00 / set

$999.00 / set -

$1190.00 / set

$1190.00 / set -

$1000.00 / set

$1000.00 / set -

$899.00 / set

$899.00 / set -

$2000.00 / set

$2000.00 / set -

$2000.00 / set

$2000.00 / set -

$2500.00 / set

$2500.00 / set -

$6000.00 / set

$6000.00 / set