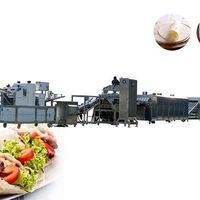

Spaghetti Pasta Machine / Pasta Making Machine Plant / Pasta Production Line

-

Supplier: Jinan Saibainuo Technology Development Co., Ltd. -

Region: Shandong, China -

Contact: Mr Zhao Zhang -

Price: $38000.00 /set -

Min. Order: 1 set

| Weight: | 800kg; | Usage: | Produce Pasta; |

| Warranty: | 1 Year; | Name: | Pasta Production Line; |

| Product name: | Pasta Making Machine; | Condition: | New; |

| Place of Origin: | Shandong China (Mainland); | Package Preview: | https://sc01.alicdn.com/kf/HTB1KZnYfHuWBuNjSszgq6z8jVXap.jpg_640x640.jpg,https://sc02.alicdn.com/kf/HTB16cnYfHuWBuNjSszgq6z8jVXaa.jpg_640x640.jpg; |

| Color: | Meatl Color; | Dimension(L*W*H): | Modle; |

| Voltage: | Customized; | Package Type: | Wooden case; |

| Production Capacity: | 120kg/h; | Certification: | ISO CE SGS; |

| Single package size: | 325X100X160 cm; | Export countries: | Global; |

| Brand Name: | SBN; | After-sales Service Provided: | Field installation, commissioning and training; |

| Single gross weight: | 1,000 KG; | Type: | Noodle; |

| Function: | Multifunction; | Selling Units: | Single item; |

| Performance: | High Efficiency; | Material: | Stainless Steel; |

| Application: | Food Processing Units; | Power(W): | 45kw; |

1.Introduction:

Macaroni pasta is making after extruding, slaking, forming, drying, frying and inflating. Our company has improved the pasta machine persormance by means of the marketing research and our own technology and makes the operator operate the machine easily and make the craft more perfect. This is indispensable production food equipment for everyone taking on the food profession.Spaghetti Pasta Machine is characterized by unique technique, rational configuration, high automation and stable performance. It can finish steaming, extrusion and shaping in one step without boiler

2.Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

3.Capacity: 100-120kg/h &280-300kg/h

4.Flow chart:Mixing system---Extrusion system----Cutting system---Drying system---Cooling System --Packing system

Extruder

1.Feeding System:Installed in the main machine, which feeds materials spirally, and the quantity can be adjusted. This system includes engine, screw, blender and machine shelf.

2.Extruding System:Adopts the crafts what can make the materials ripe in the low temperature by blending, cutting and extruding. Temperature control is set strictly on the roller and screw to reach criteria the materials require.

3. Cutting System:The shelf is fixed on the head of the moulds; and turns and cuts the materials motivated by the belt wheel.

4.Heating System:Divides five areas, and the heating temperature of which can be adjusted separately.

5.Transmitting System:The motive power from the main engine is transmitted to the screw through the triangle belt and decelerator.

6.Controlling System:Can control all the components of the main machine centrally.

7.Vacuum Pump.For the pasta and macaroni,the big problem is with bubbles and air inside.With the vacuum pump,which can extract air from feeding part,so there will be no any air and bubbles inside the pasta and macaroni,it will not easy broken and taste also very strong and good.

Dryer

1.Compact in frame, facilitated in operation, low occupation of space and high heating efficient.

2.Stainless steel is used on conveying belt, oven cover to guarantee the food safe.

3. Rock wool plates are used for heat preservation.

4. The drying time for the product can be adjusted by a frequency converter.

5. Forced lubrication system to lengthen the bearing life.

6. Electricity heating by infrared heating pipe by electricity.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

-

Fully Automatic Pancake Pasta Tortillas Papamoon Panada Tacos Samosa Dumplings Ravioli Spring Rolls Machine Dumpling Wrapper Making Machine

-

Household manual stainless steel curry puff pastry noodle press machine

-

Fully automatic industrial flour corn Mexican tortilla machine taco roti maker pressed bread grain products tortilla making machine

-

Customized fully automatic commercial roti chapati bread machine tortilla production line

-

Factory Roti Making Machine Home Cookware Automatic Roti Maker

-

Industrial Automatic Macaroni Making Extruder Machine Pasta Processing Line

-

Hot Sale Cereal Bar Best Price Nougat Production Line Granola Bar Making Machine

-

Artificial Rice Processing Line Rice Flour Machine for Small Factory

-

New Design Cereal Bar Machine/Rice Nutrition Bar Production Line

-

Factory Rice Machine Artificial Rice Production Line with Good Price

Other Products

-

$1999.00 / set

$1999.00 / set -

$1000.00 / set

$1000.00 / set