New Design Cereal Bar Machine/Rice Nutrition Bar Production Line

-

Supplier: Shandong Loyal Industrial Co.,Ltd. -

Region: China -

Contact: Mr Amy Guo -

Price: $5500.00 /piece -

Min. Order: 1 piece

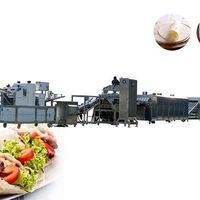

New Design Cereal Bar Machine/Rice Nutrition Bar Production Line

Cereal bars are made with main ingredients like oats, rice, nuts, dried fruit, etc. because of

Delicious taste, crisp texture, rich nutrition, easy to carry and popular in the market. It has also become the main meal replacement food for fitness people. How to make cereal bars easily?

The cereal bar production line adopts PLC operating system and advanced mechanical structure to realize fully automatic

Production - continuous feeding, automatic flattening, automatic cutting, cross-cutting. Compared with the traditional manual production method, a lot of production costs are reduced and production efficiency is improved.

By changing the ingredient recipe, the cereal bar making machine can produce many different types of products such as cereals

Bars, granola bars, peanut candy bars, puffed rice bars, nougat bars, etc. The shape of the rod can be circular, square, semicircular and triangular.

Production Process

Grain Puffing & Extrusion → Sugar Heating → Ingredient Mixer → Cereal Bar Cutting → Cooling → Packaging

Cereal bar manufacturing process

Raw materials -- black rice, sugar, nuts, corn, barley, wheat, dried fruits, raspberries, blueberries, passion fruit, sugar

Finished products--cereal bars, granola bars, peanut candy bars, puffed rice bars

1, The food contact parts are made of stainless steel 304, which meets the sanitation requirements of food QS and drug GMP.

2, Double frequency conversion system control, the bag length can be cut immediately, saving time and film.

3, High-sensitivity electric eye automatic tracking, no need to manually adjust after setting, sealing and cutting size, accurate position, firm and beautiful sealing.

4.Temperature independent PID intelligent control, stable temperature control, more suitable for various packaging materials.

5, Color touch screen display, positioning shutdown, automatic fault diagnosis, display at a glance.

6.Intelligent and user-friendly parameter design, ordinary personnel can use it skillfully in a short time. Reduce the professional skills requirements of operators.

7.A variety of cutting packaging shapes: straight, popcorn, corrugated, continuous bags, etc.

8.Suitable for moon cakes, bread, biscuits, candies, medicines, daily necessities, hardware, cartons, plastic products or various solid objects with regular shapes.

Cereal bars are made of grains such as oats, rice, corn and other grains as the main raw materials, and high-viscosity syrup is used to bond them into block and bar products; in addition to the main raw material cereals, the products will also be added with nuts, dried fruits, candy, chocolate and other smears Sauce; currently most of the cereal bar products sold in the domestic market are imported from abroad, and the products are generally in the form of a single layer, that is, surface decoration, bottom support or the entire package with a seasoning coating, such as chocolate coating, butter, condensed milk coating, etc.

All machines are made of food grade stainless steel and the conveyor lifts are also made of food grade PVC. The entire production line is made of safe and harmless materials carefully selected by our technical purchasing staff. The internal accessories are all well-known domestic brands with high quality.

The twin-screw extruder and single-screw equipment independently developed by Shandong Zhengzhi Machinery have been used in the production of: puffed snack food, breakfast cereal cornflakes, fried pasta, bread crumbs, fruit chips, baby food, tissue soy protein (TSP) food , fish feed and pet food. A variety of snack production line supporting products. At the same time, the batching, drying, tableting, baking, frying and spraying equipment matched with the twin-screw extrusion system are independently designed and produced.

Our company can provide food production equipment, technology, formula development and application for the majority of users. We are able to provide customers with complete project solutions, advice, planning, project design and engineering for food plants according to their specific requirements. Complete turnkey system, centralized control system, complete factory automation project. Provide customers with machine installation, commissioning and worker training.

www.loyalfoodmachine.com

-

Fully Automatic Pancake Pasta Tortillas Papamoon Panada Tacos Samosa Dumplings Ravioli Spring Rolls Machine Dumpling Wrapper Making Machine

-

Household manual stainless steel curry puff pastry noodle press machine

-

Fully automatic industrial flour corn Mexican tortilla machine taco roti maker pressed bread grain products tortilla making machine

-

Customized fully automatic commercial roti chapati bread machine tortilla production line

-

Factory Roti Making Machine Home Cookware Automatic Roti Maker

-

Industrial Automatic Macaroni Making Extruder Machine Pasta Processing Line

-

Hot Sale Cereal Bar Best Price Nougat Production Line Granola Bar Making Machine

-

Artificial Rice Processing Line Rice Flour Machine for Small Factory

-

Factory Rice Machine Artificial Rice Production Line with Good Price

-

Automatic China Breakfast Cereal Machine Corn Flake Making Machine

Other Products

-

$10900.00 / piece

$10900.00 / piece -

$10900.00 / piece

$10900.00 / piece -

$10900.00 / piece

$10900.00 / piece -

$5500.00 / piece

$5500.00 / piece -

$5500.00 / piece

$5500.00 / piece -

$15000.00 / piece

$15000.00 / piece -

$15000.00 / piece

$15000.00 / piece -

$15000.00 / piece

$15000.00 / piece -

$15000.00 / piece

$15000.00 / piece -

$15000.00 / piece

$15000.00 / piece