Automatic China Breakfast Cereal Machine Corn Flake Making Machine

-

Supplier: Shandong Loyal Industrial Co.,Ltd. -

Region: China -

Contact: Mr Amy Guo -

Price: $5500.00 /piece -

Min. Order: 1 piece

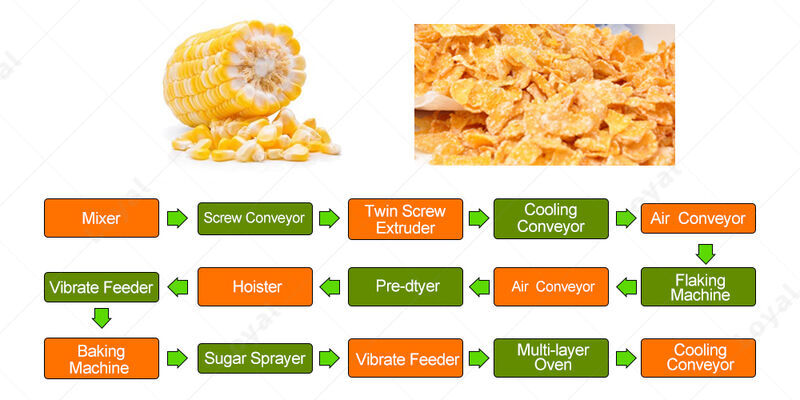

Product introduction of corn flakes production line:

Corn flakes production lineTake cornpinkAnd other grains as the main raw material, after mixing, extrusion, tableting, drying, baking, coating, cooling, to get crispy flakes. It is always used as a breakfast cereal mixed with milk. The production system can also make grains in other shapes such as rings, spheres, curls, etc.

The corn flakes processing production line can produce breakfast cereal, which is a kind of nutritious and convenient food produced by the production line. It uses cereals as the basic raw material and has different shapes such as granular, flake, and animal. A prominent feature of breakfast cereals are rich in complex carbohydrates and dietary fiber, which can fortify vitamins, minerals and other trace elements, and can also add cocoa and sugars, such as honey and maltose. Can be mixed with coffee, milk,Drink directly in yogurt or energy drinks.Kids can eat breakfast cereal as a sweet and crunchy snack.

www.loyalfoodmachine.com

Corn flakes production lineFlowchart mixer---screw conveyor

---Twin Screw Extruder---Vibrating Feeder---Drum Dryer---Air Conveyor---Tablet Press---Air Conveyor---Dryer- --Elevator ---Vibrating feeder---High temperature inflatable line oven---seasoning line---dryer---cooler.

Corn flakes production lineMachine Features

2. Screw conveyor: send the pickled raw materials into the extruder feed hopper.

3. Twin-screw extruder: The material in the feeding hopper enters the extrusion system to produce small spherical particles.

4. Vibrating feeder: Disperse particles, avoid overlapping and pressing together into aflakymachine.

5. Air Conveyor: transport the pellets to thepiecein the machine.

6. Tablet press: Flake the corn balls into tortilla chips.

7. Air Conveyor: Transfer the tortilla chips to the oven.

8 , Multi-layer oven: the oven is mostly a toaster, The temperature is between 0-200 degreesSelf-adjustment in the control cabinet, through the filter mesh bag,CanAccording to the flow adjustment,Change the water flow.

OUR SERVICE BEFORE AND AFTER PURCHASE

We provide customers with complete installation and operation manuals in English or other languages required by customers. Customers can use the same equipment to install and operate the machine.

If necessary, we can send our technicians to the customer to install the machine and charge a fee.

Our professional and technical personnel can install the machine and conduct trial production according to customer requirements.

Technicians can train operators to operate the machine at the customer site, and they will also train them to solve all problems so that they can easily manage everything without any problems in the future.

After installation, customers can ask us for help at any time through any of the following methods:

1. Call our technicians for telephone advice.

2. Get the solution by email by sending us an email.

3. Chat with our technicians in real time to get online help.

4. If necessary, invite our technical staff to the customer for troubleshooting.

-

Fully Automatic Pancake Pasta Tortillas Papamoon Panada Tacos Samosa Dumplings Ravioli Spring Rolls Machine Dumpling Wrapper Making Machine

-

Household manual stainless steel curry puff pastry noodle press machine

-

Fully automatic industrial flour corn Mexican tortilla machine taco roti maker pressed bread grain products tortilla making machine

-

Customized fully automatic commercial roti chapati bread machine tortilla production line

-

Factory Roti Making Machine Home Cookware Automatic Roti Maker

-

Industrial Automatic Macaroni Making Extruder Machine Pasta Processing Line

-

Hot Sale Cereal Bar Best Price Nougat Production Line Granola Bar Making Machine

-

Artificial Rice Processing Line Rice Flour Machine for Small Factory

-

New Design Cereal Bar Machine/Rice Nutrition Bar Production Line

-

Factory Rice Machine Artificial Rice Production Line with Good Price

Other Products

-

$10900.00 / piece

$10900.00 / piece -

$10900.00 / piece

$10900.00 / piece -

$10900.00 / piece

$10900.00 / piece -

$5500.00 / piece

$5500.00 / piece -

$5500.00 / piece

$5500.00 / piece -

$15000.00 / piece

$15000.00 / piece -

$15000.00 / piece

$15000.00 / piece -

$15000.00 / piece

$15000.00 / piece -

$15000.00 / piece

$15000.00 / piece -

$15000.00 / piece

$15000.00 / piece