Factory high price water tank making machine, septic tank making rotomolding machine

-

Supplier: Changzhou Yingchaung Rolling Plastic Equipment Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Condi Qian -

Price: $8000.00 /piece -

Min. Order: 1 piece

Product details

| After-sales service: | Overseas service machinery | Core component warranty: | 1 year |

| Function: | Plastic product manufacturing | PLC: | Siemens (Germany) |

| Minimum order quantity: | 1 set | Single piece packaging size: | 150X135X135cm |

| Mechanical test report: | if | Core components: | Programmable controller, motor |

| Product Category: | tank | Dimensions (length*width*height): | consultation service |

| Voltage: | 22V, 380V, 440V | Packaging details: | The water tank making machine is packed in standard export wooden boxes |

| Control System: | touch interface | Showroom location: | not any |

| Applicable industries: | Manufacturing factory, water tank making machine | Gross weight of single piece: | 60.000kg |

| Health status: | new | Name: | Rotational molding machine |

| weight: | 3000 | Place of origin: | Jiangsu, China |

| job type: | flames rolling | Package: | Standard export packaging |

| Video outbound inspection: | if | Main selling points: | automatic |

| strength: | consultation service | brand: | Yingchuang |

| Sales unit: | Single product | Warranty: | 1 year |

| Burner: | Riello (Italy) |

Product Description

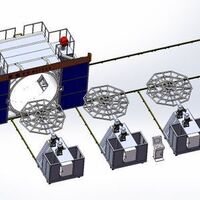

rock machine

Swing furnace machines are an extremely versatile and cost-effective way to rotationally mold large products, taking up a very small footprint compared to other machines. It is easy to operate and does not require a high enough workshop. Usage: Suitable for the production of large PE products such as water tanks, vats, tanks, ships, etc. Heat source: natural gas, liquefied gas or diesel. The heating chamber is highly insulated and consumes low energy. Real-time monitoring of heating chamber temperature to ensure product quality. Process recipes can be stored to facilitate production management. Multifunctional touch interface, reasonable and easy to operate. Fault self-diagnosis makes maintenance more convenient. Remote fault diagnosis can be achieved. Easy to load and unload the mold, saving time and effort. T fully automatic PLC control system, high production efficiency.

Specification

model | floor size | largest tank manufacturer | ||||||

Length(meter) | Width (meters) | Height(meter) | Operation platform | |||||

CO-1000 | 5 | 4.8 | 3.8 | × | 1000L | |||

CO-5000 | 5.8 | 5.6 | 4.2 | × | 5000L | |||

CO-10000 | 6.5 | 6.3 | 4.8 | √ | 10000L | |||

CO-30000 | 7.8 | 7.3 | 5.1 | √ | 30000L | |||

CO-50000 | 9.7 | 7.3 | 5.8 | √ | 50000L | |||

detailed picture

VIEW MORE

You may like

-

Rising Sun Kayak Rotomolder For Sale

-

High Quality Full Printed Plastic Ocean Kids PVC Ball Making Rubber Toys Molding Machine PVC Ball Making Machine

-

PE 500L 1000L 2000L Rotational plastic water tank machinery

-

Exporter Hot Sale Heavy Duty 4 Arms Dual Axis Rotational Molding Machine For Industrial Use

-

500 liters 1000 liters vertical water tank plastic making machine rock rotomolding machine

-

Cheapest water tank making machine Open flame machine rotary machine

-

High quality custom plastic boat rotational molding machine mold

-

Plastic thermoforming machine hollow parts rock plastic thermoforming machine

-

Balloon Making Products Machine Toy Making Rubber Soccer Small Printing Pvc Ball Making Machine

-

Rock & Roll Rotational Molding Machine For Water Tank Manufacturing For Sale

Other Products

-

$3000.99 / piece

$3000.99 / piece -

$3000.00 / piece

$3000.00 / piece -

$3000.00 / piece

$3000.00 / piece -

$3000.00 / piece

$3000.00 / piece -

$35000.00 / piece

$35000.00 / piece

Related Search

machine for making heating water tank

water tank making machine

plastic water bottle making machiner

high quality mosfet portable welding machine price

high quality garbage bag making machine

1000l water tank machine suppliers

water tank rotational mould machine

high quality sugar cube making machine

price of soap making machine

price cup plastic making machine