China Micro Brewery Equipment Supplier

-

Supplier: Shandong Innovative & Craft Brewing Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Ms Micet Brewing -

Price: $35000.00 / 1 - 4 sets

$30000.00 / >=5 sets -

Min. Order: 1 set

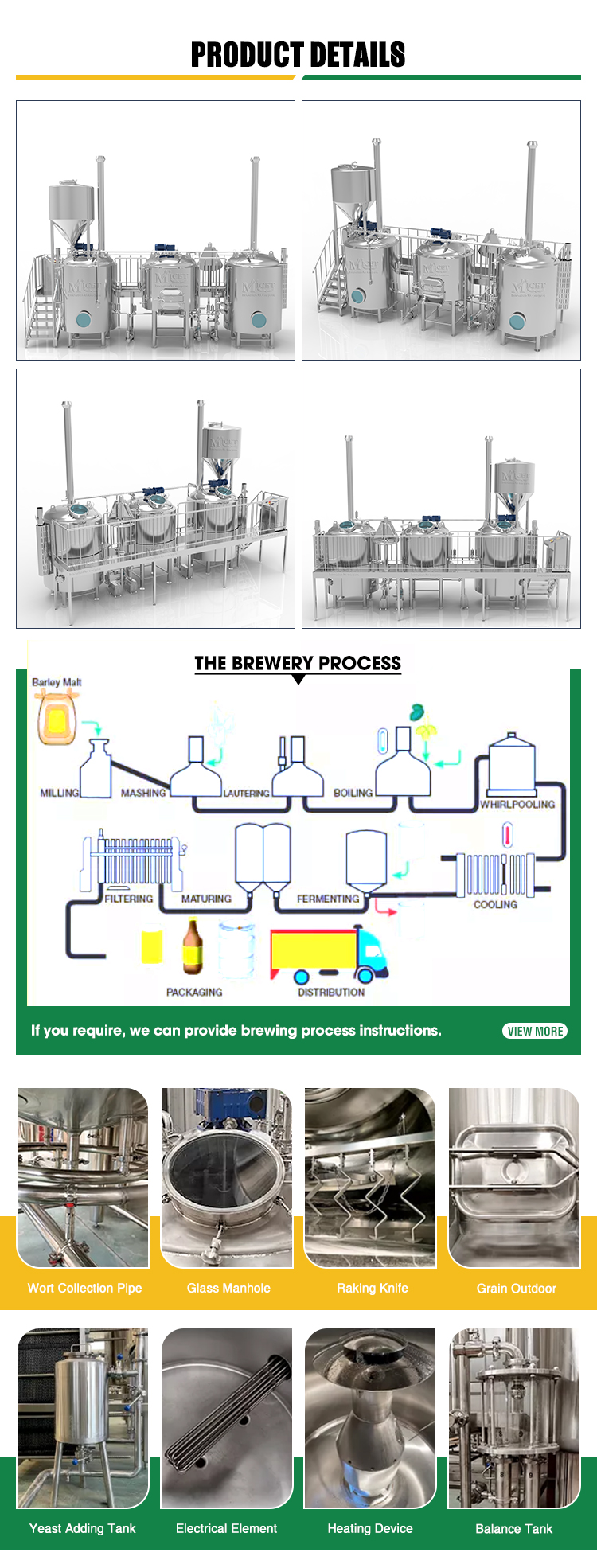

Product details

| Package preview: | Core components: | Gearboxes, motors, pumps, pressure vessels, PLCs, bearings | |

| application: | Dining room | Core component warranty: | 3 years |

| Material: | SUS304/SUS316/copper | heating method: | electric steam fire |

| brand: | mouse | port: | Qingdao |

| product name: | China Micro Brewery Equipment Supplier | Main selling points: | high productivity |

| Processing: | Fermentation equipment | Health status: | new |

| Marketing Type: | 2020 New Products | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Mechanical test report: | if | weight: | 2000 kg |

| Packaging Details: | 1. LCL/FCL (20GP/40GP/40HQ) 2. Fumigation-free wooden box plastic film packaging or iron frame fixing 3. Meet export standards and suitable for delivery 4. Can be customized according to customer requirements | strength: | 15kW-50kW |

| Origin: | Shandong Province, China | Dimensions (L*W*H): | 8600*5600*2500 mm |

| Processing type: | beer | Mechanical Capabilities: | 100L, 200L, 300L, 400L, 500L, 600L, 700L, 800L, 1000L, 1200L, 1500L, 1800L, 2000L, 2500L, 3000L, 3500L, 4000L, 5000L, 10000L, 20000L, 50000L |

| insulation: | Polyurethane/rock wool 100mm | Video outbound inspection: | if |

| cooling method: | Dimple plate cooling | Control System: | PLC |

| Supply capacity: | 10 sets per year | Function: | beer brewing equipment |

| Applicable industries: | Hotels, manufacturing plants, food and beverage factories, farms, restaurants, household, retail, food stores, food and beverage outlets | heating method: | steam electric gas heating |

| Voltage: | 220/240/380 volts | Warranty: | 3 years |

| color: | steel color | Showroom location: | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile , Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Japan, Malaysia, Australia |

China Micro Brewery Equipment Supplier

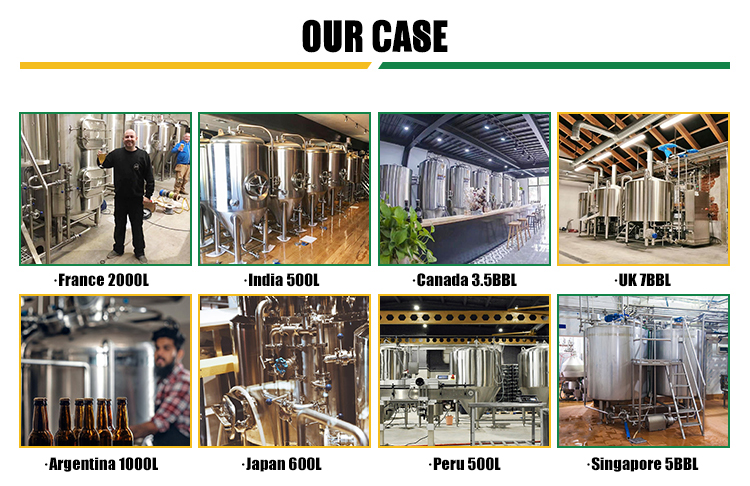

Miset is committed to the innovative design and development of the whole process of beer equipment. The equipment is suitable for small and medium breweries. Widely used in hotels, bars, resorts, entertainment venues, etc. Misai craft beer equipment is easy to operate, occupies a small area, has a high yield and a good taste.

output/brew | 500L | 800L | 1000L | 1500L | 2000L | 2500L | 3000L | 5000L | |||||||

brews/week | 2~6 | ||||||||||||||

Production/week | 10~30HL | 16~48HL | 20~60HL | 30~90HL | 40~120HL | 150~300HL | 180~360HL | 240~360HL | |||||||

regional requirements | >45 square meters | >60 square meters | >70 square meters | >90㎡ | >120 square meters | >140㎡ | >150 square meters | >180㎡ | |||||||

Winemaker | 1 | 1 | 1~2 | 1~2 | 2~3 pieces | 2~3 pieces | 3~5 pieces | 3~5 pieces | |||||||

Material | Inner shell: SUS304 TH=3mm; Outer shell: SUS304 TH=2mm / copper | ||||||||||||||

heating | Electric/steam/direct fire optional | ||||||||||||||

Voltage | Three-phase/380(220, 415,440...)v/50 (60)Hz | ||||||||||||||

Product advantages

1. According to the customer's brewing method, feeding amount and brewing beer type, the equipment design can make the beer up to 33 Plato.

2. Milling sieve plate, wedge-shaped gap 0.7mm, thickness 4mm, removable for cleaning, bottom support fixed.

3. The filter barrel is equipped with a dustpan, which is convenient for grain output and cleaning.

4. The stirring motor of the filter bucket is equipped with a frequency converter, the speed can be adjusted, and the rake can be raised and lowered.

5. The brewing kettle is equipped with an indoor steam condenser or an outdoor exhaust chimney according to the customer

6. Equipped with a special inline hop filter to make the wort clearer before fermentation.

7. The pump and motor adopt American brand ABB or JLEM, with long service life and low noise.

8. The pipeline design of the saccharification workshop is equipped with a cold and hot water mixing device, a thermometer and a flow meter, which can mix the cold and hot water evenly before saccharification.

9. There is a wort collection ring and a lower flushing device at the bottom of the lauter tank.

10. Equipped with a wort balance tank to check the clarity of the wort and protect the sieve plate.

11. The top of the tank is equipped with spray arms and double CIP cleaning circuits.

12. HLT is designed with water return port, CIP cleaning port and water inlet, which can realize the recycling of hot water between heat exchangers.

13. The working platform adopts water leakage and anti-skid design.

14. Always use all glass manholes for brewery manholes.

2. Milling sieve plate, wedge-shaped gap 0.7mm, thickness 4mm, removable for cleaning, bottom support fixed.

3. The filter barrel is equipped with a dustpan, which is convenient for grain output and cleaning.

4. The stirring motor of the filter bucket is equipped with a frequency converter, the speed can be adjusted, and the rake can be raised and lowered.

5. The brewing kettle is equipped with an indoor steam condenser or an outdoor exhaust chimney according to the customer

6. Equipped with a special inline hop filter to make the wort clearer before fermentation.

7. The pump and motor adopt American brand ABB or JLEM, with long service life and low noise.

8. The pipeline design of the saccharification workshop is equipped with a cold and hot water mixing device, a thermometer and a flow meter, which can mix the cold and hot water evenly before saccharification.

9. There is a wort collection ring and a lower flushing device at the bottom of the lauter tank.

10. Equipped with a wort balance tank to check the clarity of the wort and protect the sieve plate.

11. The top of the tank is equipped with spray arms and double CIP cleaning circuits.

12. HLT is designed with water return port, CIP cleaning port and water inlet, which can realize the recycling of hot water between heat exchangers.

13. The working platform adopts water leakage and anti-skid design.

14. Always use all glass manholes for brewery manholes.

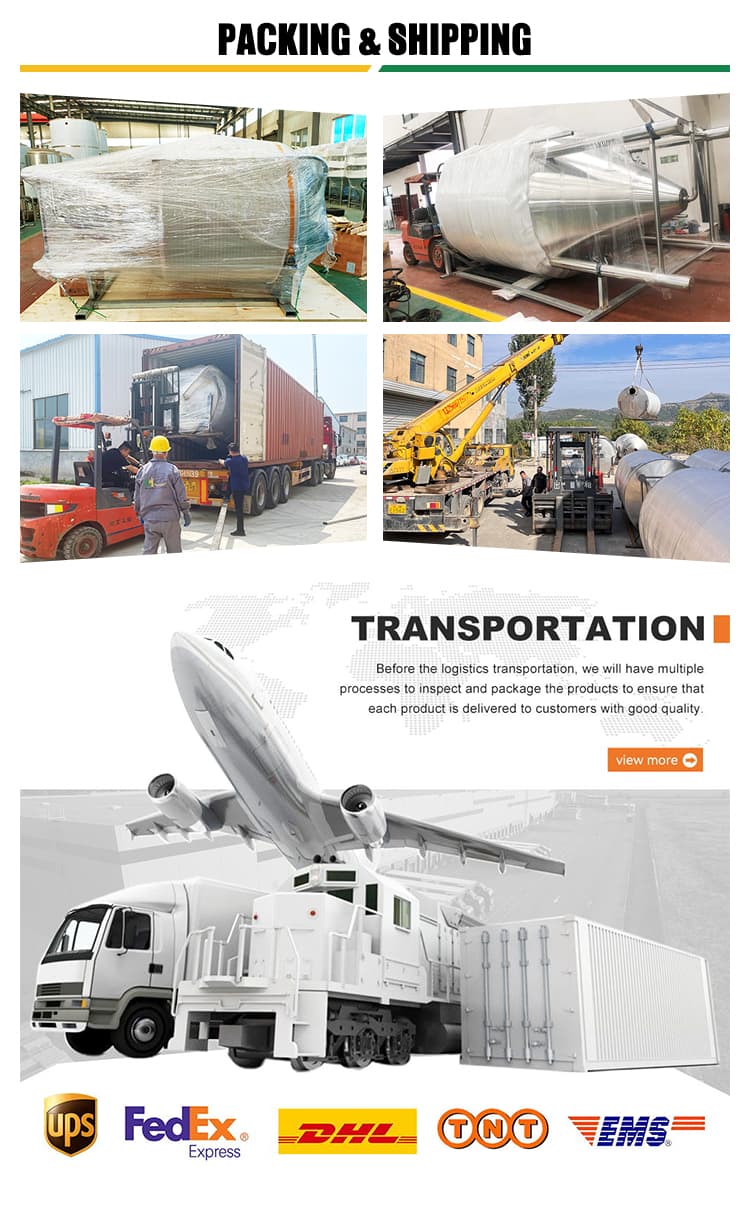

FCL shipping

1. All pipe marking numbers before shipment. At the same time, in order to facilitate the installation of customers, we will provide the whole process pipeline installation diagram according to the installation sequence.

2. All accessories of the saccharification room and fermentation room are individually counted and packaged.

3. Each of our ports will have a cover to prevent dust from entering inside during transportation. When packing, the vertical tank is fully packed to prevent sea salt corrosion; the horizontal tank is packed on a wooden skid with a steel frame, and the outriggers are fixed with threads to prevent movement during transportation. transportation.

3. Each of our ports will have a cover to prevent dust from entering inside during transportation. When packing, the vertical tank is fully packed to prevent sea salt corrosion; the horizontal tank is packed on a wooden skid with a steel frame, and the outriggers are fixed with threads to prevent movement during transportation. transportation.

our service

1. Misaite provides one-stop services from project consultation, benefit analysis, space layout design, 3D rendering, production site, equipment design, manufacturing, installation, commissioning, training, etc.

2. Micet provides installation and commissioning services and charges a service fee ($100/day).

3. Misette factory has numbered and marked all the pipes to solve any problems during your installation.

4. Misaite technicians will train brewers to produce qualified craft beer.

5. Micet provides installation and maintenance manuals, pipeline installation layout drawings.

6. 24-hour online service for sales and engineers.

7. Micet provides a 3-year warranty on tanks sold with factory manufacturing defects. Micet offers a 1 year warranty on tank fittings, pumps, electronics.

8. If extra needed spare parts, please send and deliver immediately.

3. Misette factory has numbered and marked all the pipes to solve any problems during your installation.

4. Misaite technicians will train brewers to produce qualified craft beer.

5. Micet provides installation and maintenance manuals, pipeline installation layout drawings.

6. 24-hour online service for sales and engineers.

7. Micet provides a 3-year warranty on tanks sold with factory manufacturing defects. Micet offers a 1 year warranty on tank fittings, pumps, electronics.

8. If extra needed spare parts, please send and deliver immediately.

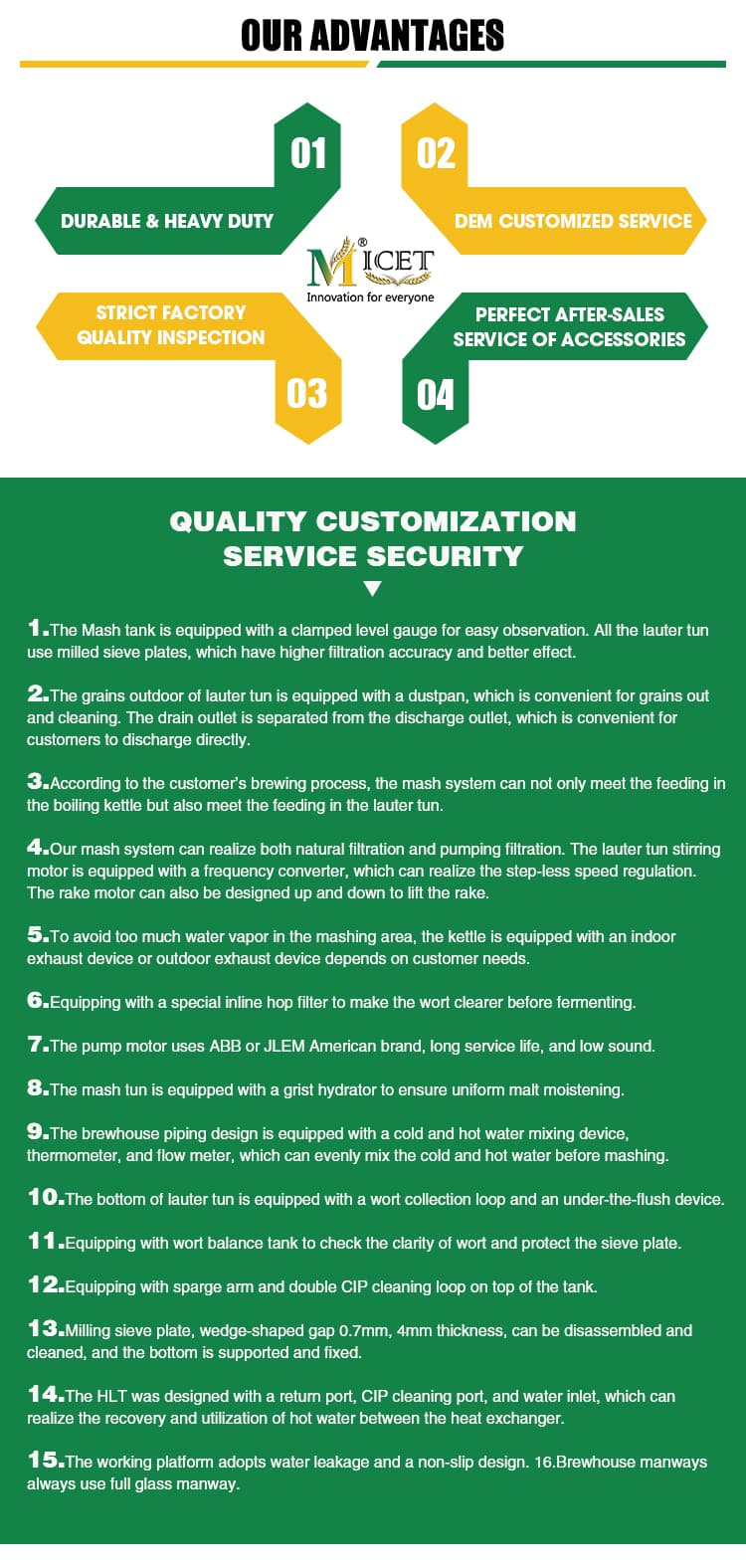

How does Micet conduct quality control?

Misaite will conduct at least 4 inspections for each order, including incoming material inspection, production process control, finished product inspection, full-line testing and inspection before shipment, to ensure that the final product meets the customer's requirements.

How to choose brewery equipment?

There are basically four types of brewery system options for purchasing beer equipment, including 2-tank breweries, 3-tank breweries, and 4-tank breweries. The combination type can be selected according to the customer's budget, space size, and local brewing process. We will also make recommendations based on the experience of old customers and the brewing characteristics of different countries.

How long is the delivery time?

1. The production time is 40 working days, and it will be executed immediately after receiving the deposit. 2. The confirmation time of technical documents (layout, drawings, etc.) is not included in the manufacturing time.

What is your payment term?

1. T/T transfer, 40% prepayment to start production, and 60% balance after payment for shipping. 2. Paypal or trade assurance is available.

Misaite will conduct at least 4 inspections for each order, including incoming material inspection, production process control, finished product inspection, full-line testing and inspection before shipment, to ensure that the final product meets the customer's requirements.

How to choose brewery equipment?

There are basically four types of brewery system options for purchasing beer equipment, including 2-tank breweries, 3-tank breweries, and 4-tank breweries. The combination type can be selected according to the customer's budget, space size, and local brewing process. We will also make recommendations based on the experience of old customers and the brewing characteristics of different countries.

How long is the delivery time?

1. The production time is 40 working days, and it will be executed immediately after receiving the deposit. 2. The confirmation time of technical documents (layout, drawings, etc.) is not included in the manufacturing time.

What is your payment term?

1. T/T transfer, 40% prepayment to start production, and 60% balance after payment for shipping. 2. Paypal or trade assurance is available.

What is your warranty period?

Host warranty for three years, free maintenance. If something goes wrong during the period. Accessories and electronic components will be covered by a one-year free warranty during this period. Anything can break during the warranty period. Replacements will be dispatched and delivered immediately. Provide daily maintenance and technical services.

Host warranty for three years, free maintenance. If something goes wrong during the period. Accessories and electronic components will be covered by a one-year free warranty during this period. Anything can break during the warranty period. Replacements will be dispatched and delivered immediately. Provide daily maintenance and technical services.

VIEW MORE

You may like

-

New WiFi Guten 40L 50L 70L Anti-burn Home Brewing All-in-one Micro Brewery/Craft Beer Machine/Brewery Equipment

-

500L 1000L Household Commercial Beer Fermentation Equipment Brewery Brewery Equipment Beer Brewing Equipment

-

3x20" Ribbon Wrap Heating Pad Warming Heater Band for Kombucha and Beer Brewing

-

High quality 5l 10l 20l translucent fermenting barrel brewing beer container with air lock for home use

-

ethanol production machinery in small capacity medical alcohol production plant

-

stainless steel olive oil storage tanks

-

Alcohol copper still whiskey distillation column with helmet for sale

-

Automatic Fermentation Barrel Venting Household Fruit Beer Enzyme Container with 2 Lids Plastic Fermentation Tank

-

For sale pilot micro craft beer producers 100 200 400 500 1000 2000 l liter 2 3 5 7 20 bbl system equipment for drinking beer

-

50L High Alcohol Alcohol Distiller For Sale, Household Stainless Steel Alcohol Distiller

Other Products

-

$5100.00 / set

$5100.00 / set

Related Search

china sheet metal equipment suppliers

micro beer equip suppliers

1200l micro brewery equipment

micro brewery equipment 500l

china gypsum board manufacturing equipment suppliers

china aligne equip suppliers

beer fermenting equipment for micro brewery

micro 1000l brewery equipment

micro beer brewery equipment

500l micro brewery for sale suppliers