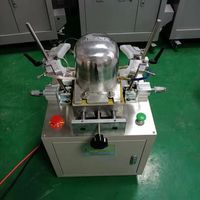

disposable bouffant cap making machine

-

Supplier: Hefei JA Machinery Co., Ltd. -

Region: Anhui, China -

Contact: Ms Lily li -

Price: $8500.00 /set -

Min. Order: 1 set

| After-sales Service Provided: | Engineers available to service machinery overseas; | Usage: | nonwoven fabric; |

| Weight: | 650KG; | Condition: | New; |

| Name: | bouffant cap machine; | Supply Ability: | 15 Set/Sets per Month bouffant cap machine; |

| Application: | Dust-free Workshop; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; |

| Brand Name: | JA; | Packaging Detail: | bouffant cap machine; |

| Warranty: | 1 Year; | Place of Origin: | Anhui China (Mainland); |

| Production Capacity: | 80-100 Pcs/min; | Automatic Grade: | Full-automatic; |

| Product: | Head Cover; | Applicable Industries: | Manufacturing Plant; |

| Dimension(L*W*H): | 3330*900*1350mm; | Payment Terms: | L/C,T/T,Western Union; |

| Color: | Light Grey; | Material: | Channel Steel; |

| Port: | shanghai; | Voltage: | 220V; |

| Certification: | CE/ISO9001; | Power(W): | 4.5 KW; |

Bouffant cap making machine

A Process Description :

Elastic, non-woven farbic feeding——Edge Folding——shaping——Welding

——cutting

Suitable:any size as your requirements.Size:21inches with double elastic

Suitable Material: non-woven farbic(15gsm-25gsm)

Voltage :220V /380V

B Technical Parameter :

Supply Power: AC220V 50HZ

Power : 4.5kw

Designed Speed : 120pcs/minute

Optimum Speed : 60-100pcs/minute

Dimensions : 3330*900*1350mm(L*W*H)

Net Weight:650kg

C Basic Mechanism

Main rack:1 set Aluminum Alloy

Raw material rack:1 set

Face plate:3pcs

Feeding device:1set

Conveying device:2set

Elastic traction device:2set

Elastic welding device:1 set

Folding device:1 set

Rotary cutting device:1 set

Welding device:2set

Ultrasonic system:3set,electric box:3pcs;Oscillator:3pcs;Horn:3pcs

D Electric Equipment and origin

1.ultrasonic :3sets

2. Motor: TaiWan “YongKun”

4. Touch screen: TaiWan “Wei- Lun”

5. Inverter: TaiWan “Sunfar”

6. PLC: Japan “Mitsubishi”

7. Sensor: Japan“OMRON”

E Operating Program

1.Adjust the non-woven farbic plate and tension equipment.

2.Pull the non-woven farbics into folding and welding manually.

3. Elastic feeding and pull into the Ultrasonic welding.

4.Open the main machine slowly,then start to welding and cutting.

G Advantages

1.This machine has aluminum alloy rack and will not get rusted permanently.

2.It’s touch-operated.

3.With imported brake and motor,it has low noise.

4.With ultrasonic welding,automatically controls tension.

5.With no manual operation from feeding materials.

Finsihed products:

Outside package:wooden package

Inside package:stretch film

2.One year warranty for you

3.Perfect and careful after-sale service

4.Fast delivery for you

5.24 hours on-line service for you

6.Engineers are available for oversea after-service

1. Q: What is your after-sales service?

A: Our after-sales service is first class. Our guarantee is one year and we can send to you freely if there is any spare part broken because of our reason. Our engineers can also go to your factory to install machines and train your workers.

2. Q: How does your factory do regarding quality control?

A: Quality is priority. We always regard great importance to quality controlling from the very small thing (even a small screw we will choose the best quality) from the beginning.

3.Q: How long is the warranty period ?

A: ONE year.

4.Q:How long is your delivery time?

A:One month

5.. Q: What is the terms of payment you accept?

A: We usually accept the T/T payment, we need 30% of total amount as deposit, pay the 70% balance upon get the copy of B/L at sight

Other Machines:

Automatic welding Machine/Ultrasonic spot weld machine/Face mask packaging machine/cotton swab making machine/gauze folding machine/face mask raw material and so on .

-

New four heads automatic visor ironing machine for making hats

-

Fully automatic small baseball cap ironing machine single head cap making machine

-

High Speed Automatic Cap Making Machine

-

Hot Sale Low Price Aluminum Baseball Cap Ironing Mold

-

CBGZ-810 Automatic High-cutting Post Bed Sewing Machine

-

Baseball cap Sweatband and visor Post Bed sewing machine

-

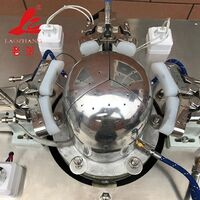

Smart medical bouffant ultrasonic cap making machine non woven strip clip mop cap making machine

-

Headwear facilities cap ironing machine-1head NE-style cap hat heat iron machinery automatic ironing machine

-

Liaode Automatic Hat making steam Cap Ironing machine

-

Fully Automatic Disposable Doctor Cap Making Machine

Other Products

-

$3200.00 / set

$3200.00 / set -

$480.00 / set

$480.00 / set -

$8800.00 / set

$8800.00 / set