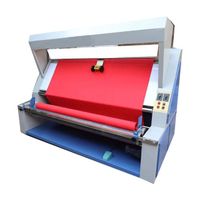

Industrial textile cloth inspection and measuring machine

-

Supplier: Zhejiang Strength Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Mindy Dong -

Price: $14000.00 /set -

Min. Order: 1 set

| Remark: | Variable working width is possible can be made as your requirements; | Item: | fabric roll inspection machine; |

| Warranty: | 13 Months; | Customize: | Available; |

| Certification: | CE ISO; | Packaging Detail: | Steel Pallet or Wooden Box Packing For SUNTECH Direct Center Driven Unwinding System Tension Control Inspection Machine; |

| Max.Re-winding Diameter: | 500mm; | Port: | SHANGHAI/NINGBO; |

| Fabric Width: | 1.8-4.0meters; | Applicable Industries: | Manufacturing Plant,Retail; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Speed: | 5-50m/min; |

| Place of Origin: | Zhejiang China (Mainland); | After-sales Service Provided: | Video technical support,Online support,Field installation, commissioning and training,Field maintenance and repair service; |

| Max.Un-winding Diameter: | 1500mm; | Dimension(L*W*H): | 4370X2350X2210mm; |

| Electric Specs: | 3phase-380V; 50HZ(can be adjusted to suit for different countries); | Power(W): | According to fabric width; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Weight: | 1300KGS; |

| Voltage: | 3Phase-380V;50HZ; | Brand Name: | SUNTECH; |

| Condition: | New; | Supply Ability: | 100 Set/Sets per Month; |

| Automatic Grade: | Automatic; | Inlet form: | Plait fabric, big roll, small roll, A-frame; |

Industrial textile cloth inspection and measuring machine

ST-BM-01 Textile Big Batch to Roll Inspection Machine is suitable for a wide range of fabrics, especially for continuous process from A-frame Batch to small rolls. This machine can provide synchronized fabric input or output to A-frame, with constant tension control. Peripheral fabric contact for delicate or heavy duty fabrics.

Main Features

2) Fabric Input, Output Synchronized- for Tensionless Roll up - Speed is controlled by an adjustable light accumulation rollers for automatic fabric synchronization.

3) Full Width Fabric Inspection - with 60 Degree Fixed Angle Inspection Screen-----Fabric can be checked under the aid of different viewing and lighting options.

4) Accurate Fabric Length Measuring - Fabric roll length can be taken by industrial standard measuring systems with digital readouts to give consistent fabric roll assessments.

5)Stable Running & Easy Operation - The whole machine is controlled by PLC and the machine can be easily operated with optional Touch Screen.

6)Stretch Fabric Control - with Scroll Roller System and Optional De-curling System. Fabric control at all times to generate consistent roll width and edge output.

7)Versatile Fabric Input and Output Options

Synchronize with Other Production Operations - Optional systems are available for different fabric input and output presentations, continuous fabric input and plait input or output.

8)Data Collection and Analysis System ( 4-point System) - Optional. 100% fabric inspection with software for accurate fabric roll analysis and printout.

Over 40 years experience, SUNTECH now has its brand office in HK and International sales office in Hangzhou. In addition, our factory is located in Ningbo city, Zhejiang, China.

Today,with more than 3000 customers and 7000 installations around the world, SUNTECH now has its agent network in Italy, Germany, Russia, Argentina, Colombia, Peru, Ecuador, Guatemala, Indonesia, Thailand, Philippines, India, Pakistan, Bangladesh, Sri

Q1: What is your advantage?

A1: Not only good quality but also good service

1. Over 45 years manufacturer

2. We have our own research and development design team.

3. We accept products customization.

4. 24 hours after-sales service and engineer oversea service.

5.Your inquiry related to our product & price will be replied within 12hours.

6.Well-trained & experienced staff are to answer all your inquiries in English of course.

Q2: Are you a trading company or manufacture?

A2: SUNTECH is a professional manufacturer with experience over 45 years. Now we have brand office in HK and International sales office in Hangzhou(Hangzhou Strength Machinery Co.,Ltd). We have factory in ningbo zhejiang. We produce machines by our factory and export machines to different countries by ourselves. Welcome to visit our factory.

Q3: How about your product?

A3: SUNTECH has the standard production and complete quality control system to ensure high quality products. Our products get ISO9001:2008, Euro CE.

Q4: How can I operate the machine?

A4: Our machine is very easy to operate. We also offer the manual and video to teach you. Welcome to visit our factory to learn more details by yourself.

Q5:Can you ship to my country?

A5:We can ship to all the countries around the world via Express,Sea,Air.

Q6: Will you provide free spare parts along with the machine?

A6: Yes, 1% to 10% of total value free spare parts will be sent with the machine for your maintenance.

We expect establishing long-term and friendly relationships with all customers.

If you want to find professional supplier of various products.

Please don't hesitate to click "Send Inquiry" now !

-

Artos Peek material slide (1 large + 2 small) + 4 brass rivet stenter dyeing, coating finishing machine

-

Ingredients Spare Parts Production Line Used Chain Price Sizing Brush Finishing Stenter Textile

-

High-efficiency production of new automatic textile finishing machine fabric double-roller machine

-

CE certification European market welcomes T-shirt automatic folding machine

-

Industrial fabric shrinkers, steam and thermosetting machines

-

Needle bar for vertical Bruckner stenter dyeing and finishing machine

-

Automatic Textile Winding Machine Cloth Winding Machine Roll-to-Roll/Fabric Winding Folding Cutting Machine/Fabric Rewinder

-

Fully automatic fabric winding fabric inspection machine roll to roll fabric cutting printing machine

-

New version of foldimate clothing folding machine automatic clothing folding machine

-

High Quality T Shirt Automatic Folder Machine Clothes Commercial Laundry Folder T Shirt Folding And Packing Machine

Other Products

-

$25000.00 / set

$25000.00 / set