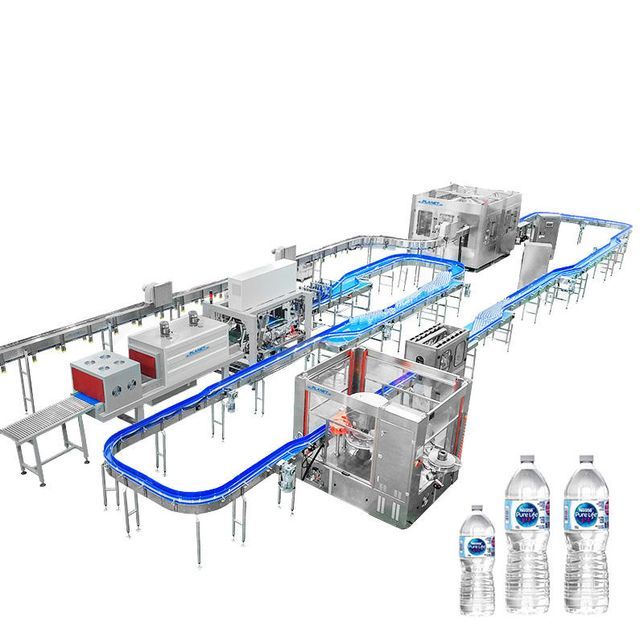

Pure water filling production line machinery PET plastic bottle water filling production line turnkey project

-

Supplier: Jiangmen Tings Drinking Water Equipment Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Janice Ye -

Price: $135000.00 /unit -

Min. Order: 1 unit

Product details

| Advantage: | Simple operation and high efficiency | Voltage: | 220/380 volts |

| Automatic level: | automatic | Control System: | PLC+touch screen |

| Year: | 2023 | pack: | wooden box |

| strength: | 50Hz/60Hz | payment terms: | L/C, T/T |

| port: | Jiangmen/Shenzhen/Guangzhou | weight: | 5000 kg |

| Key words: | Beverage production line plant | clean: | CIP system |

| Supply capacity: | 10 sets per month | capacity: | 2000-30000bph |

| Filling volume: | 200ml-2000ml | Package preview: | |

| Material: | stainless steel 304 | Machine capacity: | 6000-9000BPH |

| Filler: | drinking water | brand: | Dings |

| Packaging Details: | 1. PVC film + fumigation wooden box + solid wood pallet covering. 2. Wooden boxes suitable for long-distance sea transportation. 3. Small drinking water filling machine/beverage manufacturing equipment/juice filling equipment | Key machines: | Labeling machine, plastic bottle blowing machine, filling machine, capping machine, winding machine, sealing machine, coding machine |

| Product Category: | Sparkling water, purified water, fruit wine, mineral water | Health status: | new |

| Bottle type: | PET bottle | Origin: | Guangdong, China |

| model: | TSGX-18-18-6 |

attention:

In order to give you the exact solution and total cost of the production line, please leave us a message at the bottom of this page with the following details:

1. What kind of drink are you drinking? Water, juice, fizzy drinks or sports drinks?

2. How much BPH do you need (how many bottles per hour)?

3. Bottle size in liters or milliliters. What size?

More information about your requirements is welcome.

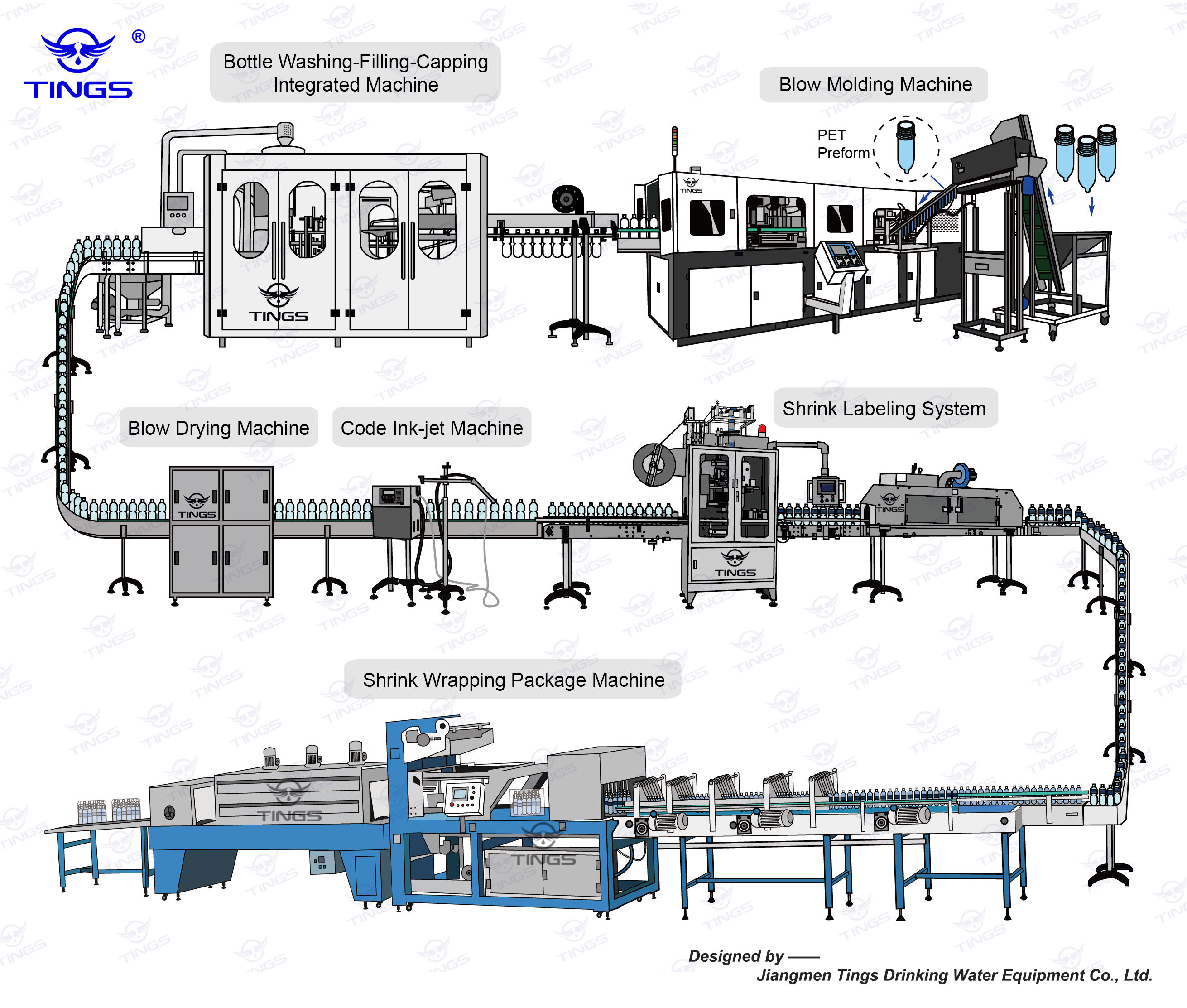

flow chart

——Bottled water filling line

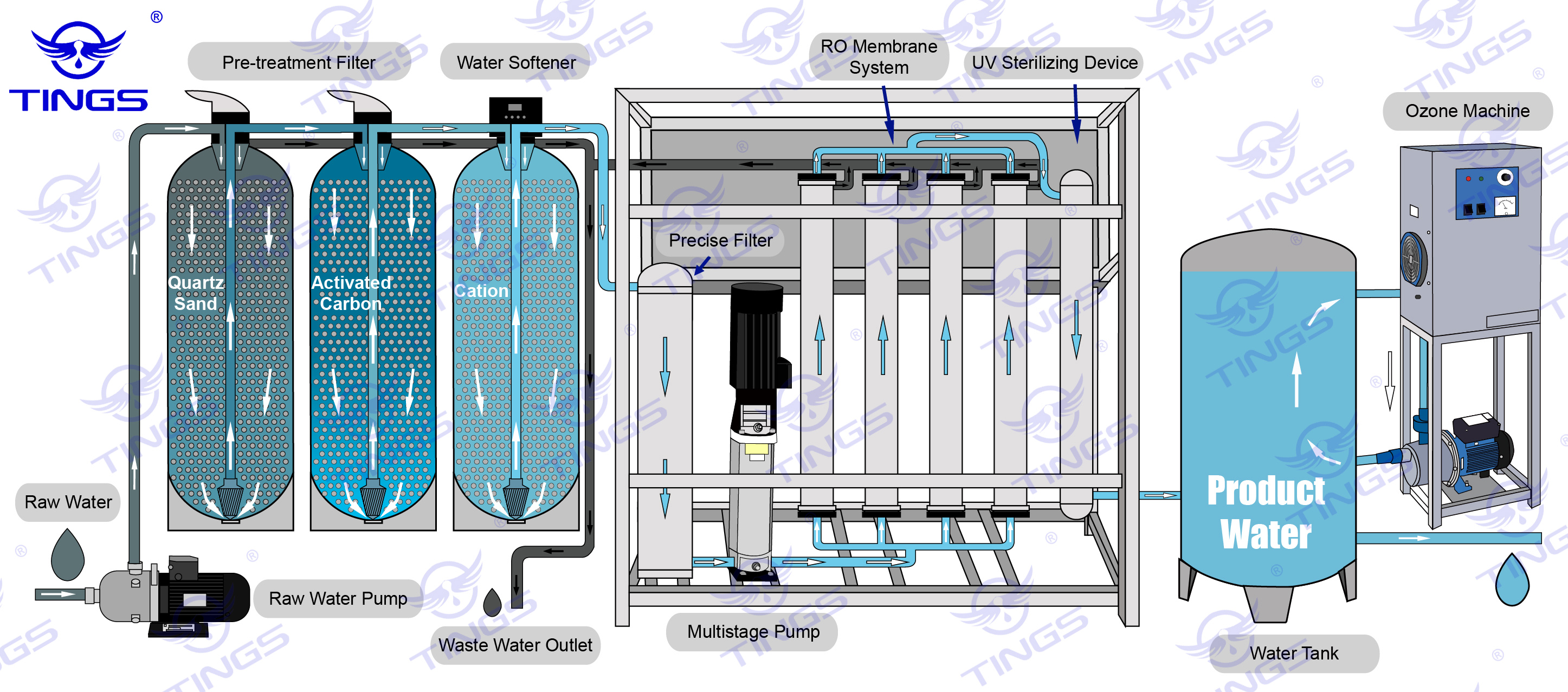

flow chart

——Water treatment system

machine details

↑↑↑↑For more information about our reverse osmosis system, please click the picture above↑↑↑↑

Raw water type: surface water, ground water, tap water, etc. (almost all liquids)

Capacity: 250L to 50000L per hourSuitable for bottled water, juice, food and cosmetic industry, irrigation, hospital use, etc.

UV sterilizer

It is an additional unit, usually installed in a reverse osmosis system, to sterilize raw water. 2000L water needs one piece.

ozone machine

It is an additional device that can produce ozone and send it into the pure water tank, so that the ozone can circulate and sterilize the water tank.

water.

water.

water tank

Used to store raw water or finished water.

↑↑↑↑ For more information about our blow molding machines, please click the picture above↑↑↑↑

Automatic Blow Molding MachineThis machine is suitable for blowing various shapes of PET water bottles, carbonated beverage bottles, fruit juice bottles, wine bottles, oil bottles, seasoning bottles, cleaning liquid bottles, container cans, etc.

Capacity: 600 to 12000 bottles per hour

Number of cavities: 2, 4 or 8

Bottle volume: 200ml to 2000ml

Maximum bottle diameter: 100mm

Maximum bottle height: 350mm

Small capacity semi-automatic blow molding machines are available.

↑↑↑↑For more information about the filling machine, please click the picture above↑↑↑↑

application:This machine is an all-in-one machine for washing, filling and capping, mainly used for non-carbonated beverages such as mineral water and purified water. It is designed to shorten the contact time between beverage materials and the outside world, improve the hygienic conditions of aquatic products, and increase economic benefits.feature:The design of hanging bottle conveying structure makes bottle conveying more convenient, faster and easier. The main engine adopts advanced PLC control, and the key electrical components adopt international famous brands.type of machine | automatic |

bottle type | PET round or square bottle Volume 200 - 2000ml Bottle diameter 50-115mm Bottle height 160-320mm |

capacity | 2,000 to 30,000 bottles per hour |

Certificate | CE/SGS/ISO9001 |

air conveyor

- The air conveyor is fixed to the floor and the fan is mounted on top.

- Air filters are located at each inlet of the fan to prevent dust from blowing into the bottle.

- The bottles are fixed at the neck on the conveyor belt and conveyed into the filling machine by blowing force.

- Made of 304/316 stainless steel.

- High quality carbon steel welded rack and frame

- Air filters are located at each inlet of the fan to prevent dust from blowing into the bottle.

- The bottles are fixed at the neck on the conveyor belt and conveyed into the filling machine by blowing force.

- Made of 304/316 stainless steel.

- High quality carbon steel welded rack and frame

hair dryer

This equipment dries the filled bottles by blowing high-pressure air.

Inkjet printer

The device prints the code onto the bottle.

Steam Shrink Labeling System

This equipment is a device for labeling bottles with high-temperature steam shrinkable plastic labels.

Shrink wrapping machine

This machine divides the bottled water into groups and wraps them with plastic film at high temperature.

VIEW MORE

You may like

-

3-in-1 3000BPH 12-12-5 fully automatic mineral water filling machine

-

Hot selling complete mini mineral water bottled water filling machine for water production line

-

Small juice processing equipment

-

Factory direct sale! 3000-12000BPH juice/drinking juice/juice beverage processing production line plant

-

Automatic production line for full processing of high quality beverages

-

Hot sale automatic beverage wine production line and wine processing machinery

-

2000 Cans Energy Drink Manufacturing Equipment Energy Drink Production Line

-

Chinese manufacturer's jujube apple grape vinegar processing machine for vinegar production line

-

Wholesale beverage production line automatic beverage production line factory

-

Five-tank CO2 mixer for fully automatic carbonation unit in soft drink processing lines

Other Products

-

$11500.00 - $12500.00 / set

$11500.00 - $12500.00 / set -

$20000.00 / unit

$20000.00 / unit