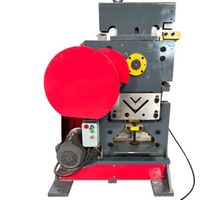

Custom Top Punch Die

-

Supplier: Anhui Aoxuan Heavy Industry Machine Co., Ltd. -

Region: Anhui, China -

Contact: Mr joe wang -

Price: $1333.00 /set -

Min. Order: 1 set

| port: | Shanghai/Qingdao, China | Energy source: | hydraulic |

| Type of machine: | burden | Model: | Deep punch |

| Voltage: | 380V | color: | customizable |

| Origin: | Anhui, China | CNC or not: | CNC |

| Key words: | ironwork | After-sales service provided: | Engineers available to service machinery overseas |

| product name: | Hydraulic blacksmith | Year: | 2022 |

| application: | Sheet Metal Stamping | Applicable industries: | Restaurant, farm, household, manufacturing plant, energy and mining, food and beverage store, construction, clothing store, advertising agency, food store, retail store, machinery repair shop, building supply store, print shop, hotel, food and beverage factory |

| Main selling points: | long lasting | Function: | metal die cutting |

| Motor power (kW): | 11 | Packaging Details: | Standard export packaging |

| Showroom location: | not any | Dimensions (L*W*H): | 1860mmx800mmx2140mm |

| Name: | iron machine | Health status: | new |

| Weight (ton): | 6.8 | brand: | Aoxuan ZG |

| type: | hydraulic excavator | Supply capacity: | 20 sets per month |

| Warranty: | 2 years | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Nominal force (kN): | 350 |

Multi-purpose 20mm thick hydraulic blacksmith Q35Y-20/hydraulic blacksmith/CE certified iron blacksmith

Aoxuan Q35Y Seriesindustrial gradeHydraulic blacksmithIt has a variety of functions, including: round hole, square hole, rectangular hole punching; steel plate, flat steel, angle steel, C-shaped channel steel, H-shaped steel punching; steel plate bending; angle steel cutting, slotting, bending; flat Shearing/cutting of steel, round bar, square bar, C-beam, I-beam, T-beam; angle bending and pipe grooving.

thisHydraulic blacksmithStandard: quick change coupling nuts and sockets, square arm with scale, electronic backgauge, measuring table with stops, punching table, safety guards, etc. Q35Y series hydraulic iron forging machine is multi-purpose, which is your first choice for similar models. Furthermore, all components are of the highest quality in terms of safety, functionality, performance and maintenance.

ourHydraulic blacksmithDesigned with the most advanced technology, it has the advantages of convenient operation, low consumption and low maintenance cost. we can alsoProvide customized solutionsIn order to better meet customer needs.

optional toolsHydraulic blacksmith

Automatic clamping system:Angle steel and plate shearing stations can choose automatic clamping system settings. In addition, fixtures will fix the position of the workpiece to save time and improve work efficiency.

Temperature Cooling System:when. . . whenHydraulic blacksmithWhen working, the oil temperature can be read through the monitoring screen. If the oil temperature is higher than the default configuration of 55 degrees, the internal cooling system will automatically operate to reduce the oil temperature to protect the hydraulic system.

two. Main Standard Property ComponentHydraulic blacksmith:

1. All electrical components are imported products with CE certificates.

2. Professional engineering design frame structure.

3. Steel welds have high strength, good rigidity and eliminate vibration.

4. Ironwork steel frame Q235=American standard steel A306 GR55.

5. Five sets of punches and blades are installed on the machine.

6. Japanese Omron timing relay.

7. All terminal blocks are manufactured by WEIDMULLER.

8. The main electrical components are from German Schneider.

9. Japanese NOK oil seal.

10. Taiwan piston pump O-rings and valves are more durable.

11. Japan Yuken hydraulic system.

12. China Jiangsu Dazhong Motor

13. The hydraulic oil tank and iron work frame manufactured by our factory.

14. Dual independent hydraulic cylinders

15. Two foot switches control the work separately

16. Easily adjustable stroke control with ruler

17. Indicators on both hydraulic cylinders

18. Electric rear gauge stops automatically

19. Removable work lights, can be placed in any desired position

20. Hydraulic system with overload protection system

21. Emergency safety stop switch

22. Large Punch Table with Guide Ruler

23. Larger slotting table with ruler guide

24. Large Flat Shear Table with Ruler Guide

25. The most important thing is easy maintenance

| Introduction to Ironworkers\Models | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | |

| Stamping pressure (T) | 60 | Post-90s | 115 | 145 | 200 | |

| Maximum Cutting Thickness(mm) | 16 | 20 | 25 | 30 | 40 | |

| Sheet strength (N/mm²) | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | |

| Shear angle (°) | 7 | 8 | 8 | 8 | 8 | |

| One cut size(mm) | 16x250 8x400 | 20x330 10x480 | 25x330 16x600 | 30x335 20x600 | 40x335 30x600 | |

| Slider stroke(mm) | 80 | 80 | 80 | 80 | 100 | |

| Number of strokes (per minute) | 12--28 |

18--30 years old | 9--18 | 8--16 | 8--16 | |

| Throat depth(mm) | 300 | 355 | 400 | 600 | 600 | |

| Punching depth(mm) | 16 | 20 | 25 | 28 | 30 | |

| Maximum punching diameter (mm) | 25 | 30 | 35 | 38 | 40 | |

| Main power(kw) | 7.5 | 7.5 | 7.5 | 11 | 18.5 | |

| Dimensions(L*W*H)(mm) | 1700x750x1800 | 1950x900x1950 | 2355x960x2090 | 2800x1100x2500 | 2800x1100x2500 | |

| Weight (kg) | 1800 | 2200 | 4800 | 6200 | 9200 | |

| round rod | 45 | 50 | 60 | 65 | 70 | |

| Square stick | 40x40 | 50x50 | 50x50 | 55x55 | 60x60 | |

| Isometric | 90° shear | 125x125x12 | 140x140x12 | 160x160x14 | 180x180x16 | 200x200x18 |

| 45° shear | 70x70x8 | 70x70x10 | 80x80x7 | 80x80x10 | 80x80x10 | |

| T-bar | 90° shear | 120x120x12 | 140x70x12 | 160x160x14 | 180x180x16 | 200x200x18 |

| 45° shear | 60x60x8 | 70x70x10 | 80x80x10 | 80x80x10 | 80x80x10 | |

| I-beam | 126x74x5 | 200x102x9 | 200x102x9 | 280x124x10.5 | 280x124x10.5 | |

| channel | 126x53x5.5 | 160x60x6.5 | 200x75x9 | 280x86x11.5 | 300x89x11.5 | |

-

New high productivity metal and steel manufacturing plant construction engineering steel processing small punching and shearing machine

-

Chinese manufacturer QA32-8B angle iron cutting machine

-

APEC hydraulic punching die - round hole / oval hole punching

-

Q35y hydraulic sheet metal steelworker shear punching machine

-

Hydraulic combined punching and shearing machine for sale ironworking machine combined punching and shearing machine

-

Professional hydraulic combined sheet metal working machine

-

APEC small hydraulic ironworking machine punching plate shear multi-function

-

Small hydraulic iron punching machine mechanical punching and shearing machine

-

Anhui Haili CNC sheet cutting machine adopts hydraulic cutting machine

-

Factory inventory Q35Y series steel ironwork hydraulic steel punching and shearing machine steel punching and shearing machine

Other Products

-

$1260.00 / set

$1260.00 / set -

$1500.00 / set

$1500.00 / set -

$1252.00 / set

$1252.00 / set