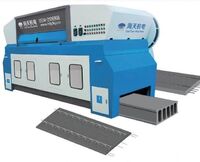

Prestressed concrete slab forming machine for prefabricated half slab/concrete floor machine

-

Supplier: Dezhou Haitian Electromechanical Technology Co., Ltd. -

Region: Shandong, China -

Contact: Ms. Haitian Machinery -

Price: $20000.00 /set -

Min. Order: 1 set

Product details

| Local service location: | Italy, Vietnam, Philippines, Brazil | Voltage: | 220v, 380v |

| Certification: | ISO9001:2008 Certificate | Warranty: | 1 year |

| port: | Tianjin, Qingdao | Production speed: | 1.5-2m/min |

| Dimensions (L*W*H): | 4.3*1.8*2.3M | Main selling points: | High capacity |

| Packaging Details: | rotten parcel | strength: | 4525KW |

| use: | Fabrication of prefabricated ribs | weight: | 7.5 tons |

| Applicable industries: | factory, construction | brand: | Haiyu |

| Production capacity: | 1.2-1.4m/min | Health status: | new |

| Origin: | Shandong China | Showroom location: | Italy, Vietnam, Philippines, Brazil |

| payment terms: | L/C, T/T, Western Union | Supply capacity: | 1 unit per quarter |

| After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services | After-sales service provided: | Online support, free spare parts, on-site installation, commissioning and training, on-site maintenance and repair services, video technical support |

Product Description

Applications

Prestressed concrete composite slab (or concrete half slab) is a simple way of floor construction. It combines prefabricated and cast-in-place concrete, has the characteristics of high rigidity, good crack resistance, no need to use steel bars, saves formwork, etc., and has the integrity advantages of cast-in-place slabs.

The span is generally within 8 meters, and can be widely used in construction projects such as hotels, office buildings, schools, residences, hospitals, warehouses, parking lots, and multi-storey industrial plants.

Production Line Details

1. Concrete feeder

1. The feeding machine includes a hopper and an electric control system; 2. The system is equipped with anti-collision stop mechanism, overload protection and other devices to ensure stable performance and smooth operation of the equipment.

2. Concrete placing machine

1. This machineAutomatic distribution of concrete material to workbenches, dispensersHopper volume 2m³;

2. The moving speed of the machine is adjustable; 3. The batching machine has 10 batching ports, and the discharge door can be controlled separately;

3. Vibration machine

1. The machine automatically vibrates the concrete evenly,Adjustable moving speed;

2. The vibrating part can move left and right, and the vibration range matches the platform; 3. The vibrating machine is equipped with 8 vibrating rods, which can be controlled individually;

4. Bed Cleaner

This machine can help save labor and improve work efficiency.

1. Clean the residue and dust on the platform;2. Automatic spraying of release agent; 3. Laying of steel wire along the casting table;

5. Cover car

1. The main function is to lay a thermal insulation and moisturizing film before curing the half board, and collect the film after the curing is completed; 2. Roughen the parts.

VIEW MORE

You may like

-

China wood/medium density fiberboard/particle board/plywood automatic coating machine

-

Furniture cabinet MDF plywood wood board plastic board coating machine

-

Fully automatic SPC floor production line extruder cutting DET V groove spray paint IXPE laminated packaging

-

Concrete prestressed hollow slab simple production line

-

Prefabricated Hollow Cement Roof Panel Forming Machine for Prefabricated Houses

-

Laminate SPC Floor Automatic Turning Equipment Turning Machine

-

China Plywood Wood Processing Machinery Manufacturer China Supplier

-

hotjin floor woodworking machine

-

PVC LVT EVA Rubber Floor Hydraulic Cutting Machine

-

Precast concrete Floor slab machine FOR Prefab house

Other Products

-

$1000.00 / set

$1000.00 / set -

$5999.00 / set

$5999.00 / set -

$160000.00 / set

$160000.00 / set -

$30000.00 / set

$30000.00 / set -

$26800.00 / set

$26800.00 / set -

$15000.00 / set

$15000.00 / set -

$6000.00 / set

$6000.00 / set -

$12000.00 / set

$12000.00 / set -

$7500.00 / set

$7500.00 / set

Related Search

beam slabs forming machine suppliers

pvc vacuum forming cover for machine equipment

metal sheet roll form machin for sale suppliers

760 arched color roll forming machine for steel

concrete tubes form machine

vacuum forming machine for acrylic

cnc spring forming machine

concret floor cut machin

plastic tray forming machine china sale

glass forming machine