Automatic Heat Press Vacuum Film Press Vacuum Press

-

Supplier: Jinan Grace Industry Co., Ltd. -

Region: Shandong, China -

Contact: Ms Grace Machinery -

Price: $6710.00 /set -

Min. Order: 1 set

| Warranty: | 1 year | Key words: | Vacuum Laminator |

| Packaging Details: | wooden box | brand: | grace |

| Name: | vacuum press | Applicable industries: | Hotels, clothing stores, building supplies stores, machinery repair shops, manufacturing plants, food and beverage factories, farms, restaurants, home use, retail, food stores, printing shops, construction, energy and mining, food and beverage stores, advertising agencies |

| Material: | wood, PVC | Supply capacity: | 70 automatic heat press machines per month |

| weight: | 1350 kg | payment terms: | L/C, T/T, Western Union |

| After-sales service provided: | Online support, engineers are available to repair machinery overseas | color: | white |

| strength: | 5.5kw | Voltage: | 220V/380V |

| Health status: | new | Woodworking machinery: | Bending plywood presses |

| port: | Qingdao | Certification: | International Organization for Standardization |

| Origin: | Shandong China |

Automatic Heat Press Vacuum Film Press Vacuum Press

riceMachine Features:

1. In addition to stretching the film manually, all operations are automated, that is, one-button forming.

2. The power of this machine adopts international advanced progressive motor, the control part adopts high-tech PLC digital intelligent system, and the panel adopts 7-inch high-definition, high-sensitivity touch screen, which is more intuitive, convenient and high-end.

3. The transmission part adopts high-precision rack and pinion combination, bid farewell to the ancient pull rope movement, the platform runs more smoothly and accurately, and never collides;

4. The vacuum adsorption pump adopts the direct connection type, which greatly improves the advantages of pumping speed and running noise.

Heating temperature:

1. The thickness specification of pvc material is 10 wires to 50 wires, 10 wires to 25 wires, 120 to 140 degrees in spring and summer, and 130 to 150 degrees for 25 to 50 wires; 10 wires to 25 wires in autumn and winter, 130 to 150 degrees, 25 wires to 50 degrees The wire is 140 to 160 degrees, and the molding time is about 50 seconds from unpacking to the completion of the molding box.

2. It takes about 2 minutes to complete the veneer at a temperature of 140 degrees in spring and summer, and about 2 minutes in autumn and winter at a temperature of 160 degrees.

The temperature and time of thermal transfer are the same as that of veneer,

Note: For veneering and thermal transfer printing, you need to add a silicone plate to complete. The original silicone plate is not a machine accessory. If you need to add USD197.00

Vacuum pump efficiency:50 cubic meters per hour, 15 liters per second,

No. | Specification | parameter |

1 | X, Y, Z, A travel | 1300x2500x130mm |

2 | Machine Control Type | Fully automatic control + semi-automatic control system |

3 | spread | Rack & pinion (gear) |

4 | Number of workbenches | two |

5 | Workbench Control | Fully automatic control + semi-automatic control system |

6 | vacuum pump | #60 |

7 | Ultimate vacuum | -01MPA |

8 | Table feed speed | 8 seconds |

9 | total power | 28KW |

10 | Working power | 5.4KW |

11 | Overall size | 8600x1600x1400mm |

12 | net weight | 1200KG |

13 | gross weight | 1350KG |

14 | pack | Two packs: 2700*1600*1580 & 3000*1600*1600 |

Photos of machines in the factory:

sample:

terms of carriage

sea route

payment terms

1. T/T (Telegraphic transfer)

2. L/C at sight

3. Hosting

4. Western Union

5. By sea, 50% in advance, the balance against the copy of the bill of lading.

Advantage

1. Competitive price

2. Good reputation and considerate service.

3. Excellent quality

4. Fast delivery

good after-sales service

1. The whole machine is guaranteed for one year. We will provide one year warranty for machine parts, within one year, we will repair or replace damaged machine parts for buyers free of charge.

2. Free training in our factory.

3.24 hours online service via TM, Skype, MSN, email or phone.

4. Engineers can provide overseas training and after-sales service.

5. If you have any questions about the machine, please feel free to contact me.

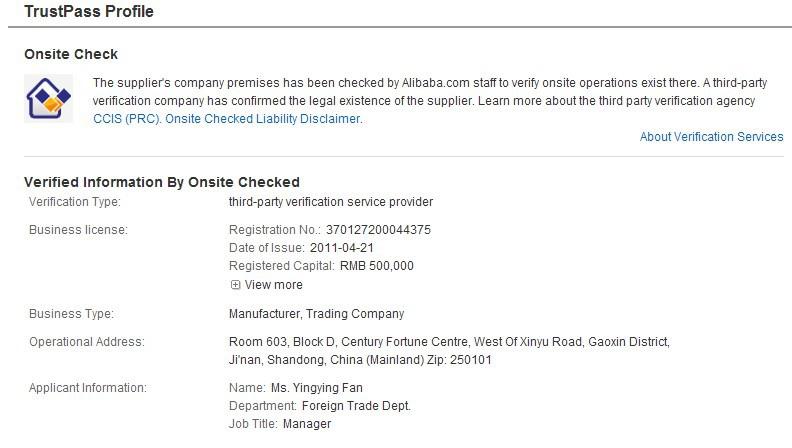

certified

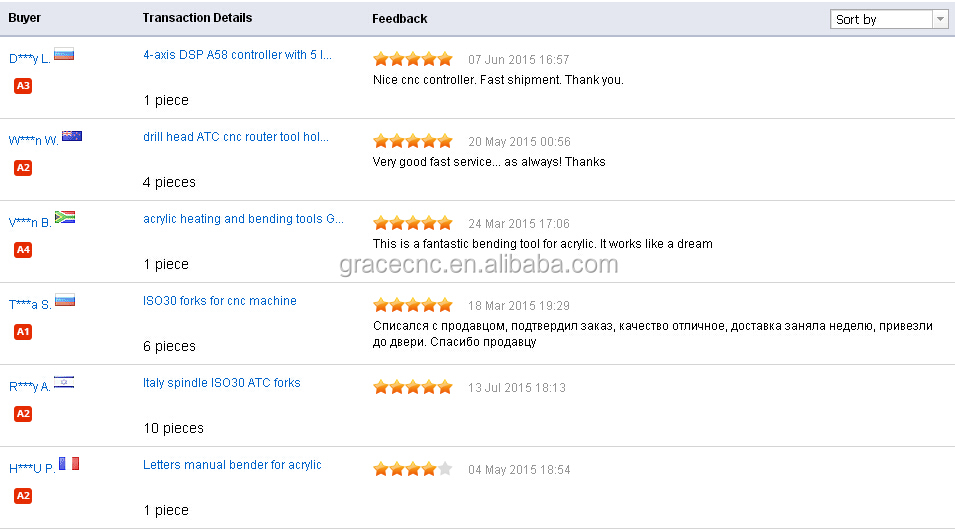

Customer Feedback

packaging and shipping

-

Wooden door cold pressing woodworking machine wood refrigeration oil press

-

Factory Price MH3248*50T Plywood Door Production Line Hydraulic Cold Press Machine

-

Woodworking hydraulic heat press 200 tons

-

Furniture cold press machine 3000mmx1500mm / Plywood cold press machine

-

Wholesale veneer hot pressing equipment

-

120 tons woodworking machinery door heat press XBD-BY214-120T

-

hot press melamine laminating machine

-

120 ton wood hydraulic plywood hot press machine

-

Shiny 15 ply plywood veneer heat press machine

-

4 hot press hot plate