2021 Hot Sale Roller Door Roller Machine

-

Supplier: Botou Kaiyite Cold Bending Machinery Co., Ltd. -

Region: Hebei, China -

Contact: Mr Berton Zhang -

Price: $3900.00 /set -

Min. Order: 1 set

Product details

| delivery time: | 40 days after deposit | Side panels: | 14mm |

| strength: | 3 kW | Control system brand: | delta or as needed |

| Cutting type: | Sawing | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Main selling points: | high productivity | Core component warranty: | 2 years |

| Voltage: | 380V | Roller stage: | 12 forming stations + 5 straight rollers |

| weight: | 1300 kg | Supply capacity: | 30 sets per month |

| Mechanical test report: | if | Applicable industries: | Hotels, clothing stores, building materials stores, manufacturing plants, farms, restaurants |

| Marketing Type: | normal product | brand: | Jingdong |

| Production capacity: | 10 meters per minute | Working Thickness: | 0.7-1.2mm |

| application: | Building Construction | Core components: | Motor, PLC |

| product name: | 2021 Hot Sale Roller Door Roller Machine | Total power: | 3 kW |

| Showroom location: | U.S. | Packaging Details: | 1. We will rub anti-rust oil for the whole machine. 2. Plc controller will be covered by foam film 3. Spare parts are some small parts packed in wooden case. 4. All parts are fixed with steel wire and container. |

| Warranty: | 2 years | Video shipment inspection: | if |

| Roller material: | 45# steel chrome plated | Applicable materials: | stainless steel, aluminum, galvanized steel |

| Package preview: |

Product Description

2021 Hot Sale Roller Door Roller Machine

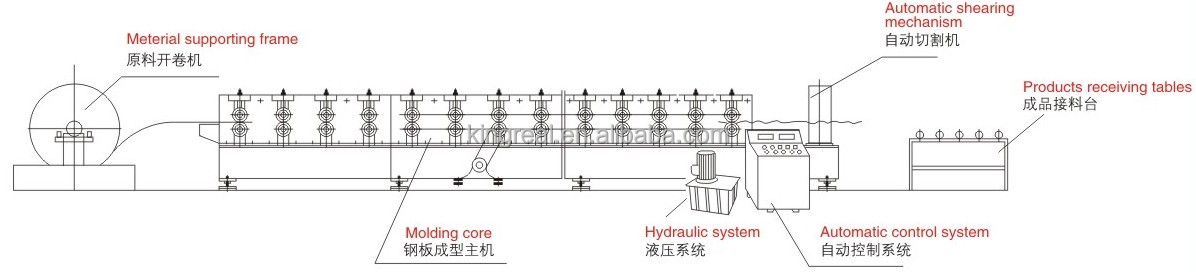

A roll-up door is a door that consists of many horizontal slats that are hinged together. The shutter slats are lifted and lowered by the door opener, and the door body is opened and closed along with the door body guide rail.

Specification

2021 Hot Sale Roller Door Roller Machine | ||

Metal material thickness | 0.7 - 1.2 mm | |

Metal Material Width | 125mm or according to customer requirements | |

drum stage | 12 rows forming | |

Roller material | 45# forged steel chrome plated | |

Shaft diameter | Φ40mm | |

Cutting blade material | Cr12Mov, quenching treatment 58°C-60°C | |

The main structure of the machine | square tube | |

machine side panel | 14mm | |

cutting type | hydraulic cutting | |

Motor Power | 3 kW | |

Sawing power | 0.75 kW | |

productivity | 8-12m/min | |

PLC control system | Delta or according to customer requirements | |

Product Details

Name: Manual Uncoiler

usage:It is mainly used to support the steel coil, and manually uncoil and straighten the steel coil and send it to the feeding table.

Coil Width:200 mm. (According to your actual drawing)

Loading Capacity :1.5T

the inside diameter of:500-508mm

Coil Width:200 mm. (According to your actual drawing)

Loading Capacity :1.5T

the inside diameter of:500-508mm

Name: Feeding table

usage: Used to control the width and position of the steel plate, guiding it to the correct position of the machine to ensure that the panels are neat and parallel.

Other Accessories:The hand knife cuts the material and controls the feed length, saving material.

Other Accessories:The hand knife cuts the material and controls the feed length, saving material.

Material:High quality 45# steel

feature:Forged, polished, heat treated and finally chromed, they are extremely strong and resistant to wear. At the same time, the roof tiles are smooth and burr-free.

feature:Forged, polished, heat treated and finally chromed, they are extremely strong and resistant to wear. At the same time, the roof tiles are smooth and burr-free.

Name: Sawing

Material:Cr12mov

feature:Quenching before heat treatment ensures surface finish and hardness.

work processing

VIEW MORE

You may like

-

Aluminum profile cutting saw machine with digital instrument

-

Aluminum door and window back-to-back assembly table

-

PVC window double-sided seamless welding machine

-

90 or 45 degree aluminum angle cutting machine door and window aluminum profile cutting machine

-

Made in China High quality single head Upvc profile 45 degree angle miter saw

-

Popular machines for drilling aluminum door and window profiles

-

Aluminum Door and Window Frame Manufacturing Equipment Aluminum End Mill Machine Motor Offers Aluminum Cutting Machine

-

Made in China manufacturing door and window aluminum pneumatic punching machine

-

Electric Portable Corner Cleaning Handle Tool for Small Workshop Upvc Door and Window Manufacturing

-

45 90 Degree Aluminum Single Head Cutting Saw Aluminum Door and Window Machinery

Other Products

-

$5000.00 / set

$5000.00 / set

Related Search

hot billet roller machine suppliers

hot sale walnut oil pressing machine

hot sale ultrasonic lace sewing machine

sales used door frame machine

roller door rolling machine

hot sale 16oz popcorn machine

hot emboss roller suppliers

hot sale flavored popcorn machine

hot sale enamelling machine

dynapac roller machin suppliers