MPD520: 0.2%FS 4-digit 7-segment dual 2-channel programmable digital process indicator with optional RS485, relay, 4-20ma output

-

Supplier: Xiamen Madincos Automation Co., Ltd. -

Region: Fujian, China -

Contact: Ms Mrs.Cindy Sun -

Price: $30.00 / >=2 sets -

Min. Order: 2 sets

Product details

| payment terms: | L/C, Western Union, T/T, MoneyGram, alipayment, alitrade guarantee | power supply: | 100-240VAC; 24V DC |

| LED display: | 7-segment 4-digit LED display | place of origin; place of origin: | Fujian China |

| Supply capacity: | 10000 sets per month Universal Input Digital 7 Segment LED Display Process Indicator | Customization support: | OEM,ODM,OBM |

| accuracy: | +-(0.2%FS+1) bits | product name: | Universal Digital Process Indicator |

| Warranty: | 1 year | Relay output: | Normally open, normally closed, 0.8A |

| Retransmit output: | 4-20ma, optional | Programmable general purpose input: | Thermocouple, RTD, pt100, 4-20ma, 0-10ma, 0-5vdc, 1-5vdc, 0-10vdc, mv |

| size: | 48x96x100mm | Auxiliary output: | 5VDC, 12VDC, 24VDC built-in, optional |

| Packaging Details: | pc+bubble bag+box+carton (MPD520: 0.2%FS 4 Digit 7 Segment Dual 2 Channel Programmable Digital Process Indicator with optional RS485,Relay,4-20ma Output) | port: | Xiamen |

| Newsletter one: | RS485, RS232 standard MODBUS-RTU protocol | brand: | Martin Cos |

| model: | MPD520 | Package preview: |

0.2%FS 4-digit 7-segment dual 2-channel programmable digital process indicator with optional RS485, relay, 4-20ma output

product display

Specification Model: MPD520 | ||||||

accuracy | accuracy | ±(0.2%FS +1) digit | ||||

power supply | 100-240VAC; 24VDC | |||||

Dimensions/installation dimensions | 48x96x100mm | |||||

show | 4-digit 7-segment LED display | |||||

Response time | <0.5 seconds when fliter=0 | |||||

input specifications | ||||||

Number of input channels | 2 channels | |||||

input type | Thermocouple, RTD, analog: 4-20ma, 0-10ma, 0-5VDC, 0-10VDC, flexible button programming | |||||

compensation | Built-in automatic. Thermocouple Cold Junction Compensation for Thermocouple Inputs | |||||

filter | 0-99, programmable | |||||

offset | 0-2000, programmable | |||||

hysteresis | 0-2000, programmable | |||||

input type | scope | input type | scope | ||||

Thermal resistance | PT100 | -200 to 600°C | thermocouple | Potassium | -50 to 1300°C | ||

CU50, CU100 | -50 to 150°C | Jay | 0~1000℃ | ||||

4-20 mA | -20000 to 20000 | Ton | -200 to 350°C | ||||

0-10mA | -20000 to 20000 | Second | 0~800℃ | ||||

0-5VDC | -20000 to 20000 | R | -50 to 1700°C | ||||

1-5VDC | -20000 to 20000 | small | -50 to 1700°C | ||||

Second | 300 to 1800°C | ||||||

no | 0 to 1300°C | ||||||

Modular output specifications: OUT1: OUT2, OUT3 | ||||||||

relay | Normally open, normally closed, normally open + normally closed, 0.8A | |||||||

communicate | Isolated RS485, RS232 standard Modbus-rtu protocol, | |||||||

Retransmission | Isolated 4-20ma 2-wire transfer output | |||||||

Print | Numeric and curve data printout | |||||||

feed | Isolated 5VDC, 12VDC, 24VDC built-in transmitter and sensor auxiliary power supply | |||||||

PC software (communication) | Powerful software functions: the data is displayed and monitored in real time on the PC in the form of digital curves, the data is printed and exported to for further analysis; data is automatically stored in the PC at the same time | |||||||

detailed image

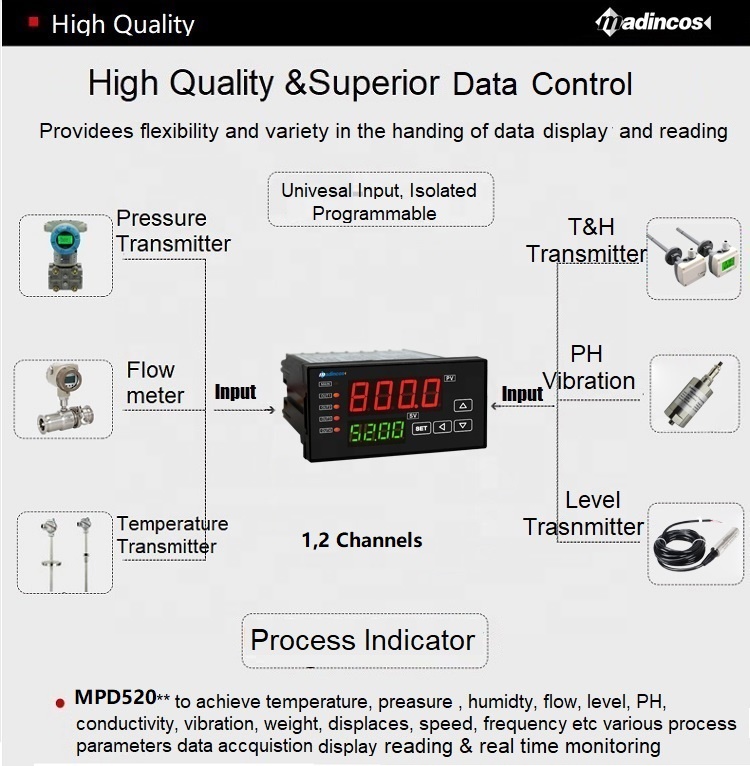

Powerful universal input, the input type can be programmed by keys, and it can be used in one instrument with various sensors and transmitters, which is convenient for users to use

** Data collection and reading of various process parameters such as temperature, pressure, humidity, flow, liquid level, PH, conductivity, vibration, weight, displacement, speed, frequency, etc.

Temperature, Humidity, Pressure, Flow, Level, Vibration Applications:

Room, warehouse, boiler, furnace, HAVC, library, cold room.

Petroleum, chemical industry, pharmaceutical, metallurgy, papermaking, electric power, nuclear power,

food, cement, construction, aviation, medical university laboratories,

ocean, sewage, water supply, river

Machines, pumps, motors, fans, engineers, etc.

................................................

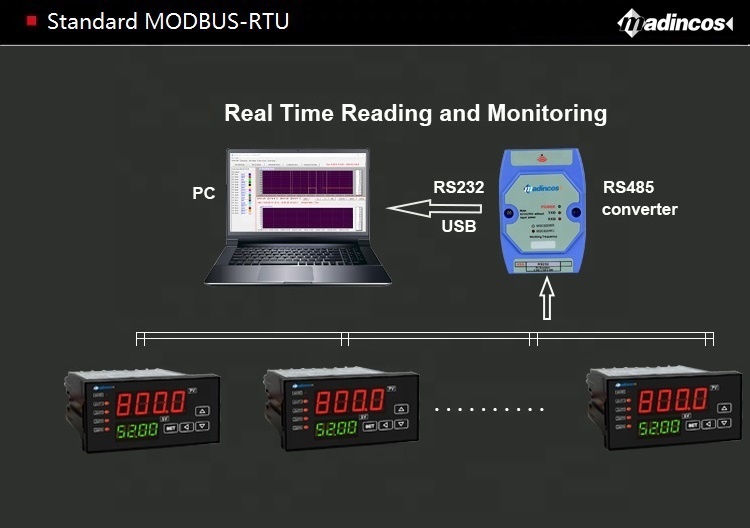

*RS485, RS232 serial communication real-time reading and PC remote monitoring (optional)

*Photoelectric isolation RS485,RS232 MODBUS-RTU Comm.

*Standard MODBUS-RTU protocol, flexible configuration with SCADA, DCS, PLC, HMI, OPC servers, to realize remote real-time reading and monitoring in the control room

*Standard MODBUS-RTU protocol, flexible configuration with SCADA, DCS, PLC, HMI, OPC servers, to realize remote real-time reading and monitoring in the control room

*Baud rate: 9600, 4800, 19200 by default.

*Address: 1 to 254

*Address: 1 to 254

* Powerful PC software (optional)

Our DCS software can realize real-time monitoring and automatic reading of PC memory data, which is convenient for users

* Display real-time data in the PC software in the form of numbers and curves, which is convenient for PC remote reading and monitoring.

* The stored data can also be displayed in the form of numbers and curves, and the curve data can also be printed with a printer, and the data can also be exported to excel for further analysis.

* The stored data can also be displayed in the form of numbers and curves, and the curve data can also be printed with a printer, and the data can also be exported to excel for further analysis.

VIEW MORE

You may like

-

High precision 0-0.12mmx0.001mm indicator micrometer gem dial indicator test indicator

-

Dial inner diameter gauge 18-160mm 0 01mm center ring micrometer measuring tool dial indicator OEM origin range reading

-

501E Floor Scale Floor Scale Digital Weighing Indicator

-

2022 New Hot Dial Gauge Magnetic Holder Tool Set 0-10mm 0-1 inch Indicator Adjustable Magnetic Base

-

ROKTOOLS Imperial Dial Indicator with 2" Travel and 0.0005 Increments

-

Chrome Plated Manual Dial ID Gauge 2"-6"/0.001" Extended Dial ID Gauge Set Self-Centering ID Gauge Set with Carbide Anvil

-

Mid-year promotion 60kg flexible magnetic dial indicator holder

-

Yiwu metric and imperial resolution 0.01mm coaxial centering dial indicator

-

Industrial grade measuring tool mechanical pointer inner diameter 18-35 weight percent scale

-

Portable precision mechanical measuring dial indicator dial indicator for laboratory

Related Search

digital dial indicator

digital temperature indicator

measuring digital price indicator

good digital dial indicator

digit univers indicator

digital timer switch with plug suppliers

digital position indicators

digital power amplifier with usb port

digital printer machine with ink

digital hearing aid with remote control