LED bulb lamp production machine E27 B22 bulb lamp automatic assembly line bulb crimping aging test machine

-

Supplier: Shenzhen Carst Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Charlie Yang -

Price: $1000.00 /set -

Min. Order: 1 set

Product details

| brand: | casto | Marketing Type: | hot product |

| usage: | light bulb assembly line | Boxing machine: | PCB board punching |

| Aging line: | Ball tube mixing aging line | place of origin; place of origin: | Guangdong, China |

| Supply capacity: | 100 sets per month | assembly line: | Automatic assembly machine |

| port: | Shenzhen | payment terms: | L/C, Western Union, T/T, Money Gram, Credit Card |

| Packaging Details: | Vacuum inspection export wooden box | Package preview: | |

| Weight (kg): | 1300 | State of health: | new |

| laser marking machine: | Laser marking/parameters | Types of: | Automatic SKD production |

| Crimping machine: | Automatic capping | application: | E27/E14/B22 |

| Core component warranty: | 1 year | Dispenser: | fixed cover |

| Showroom location: | Egypt, Vietnam, India, Russia | Video shipment inspection: | if |

| capacity: | 1200pcs/hour | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| Warranty: | 1 year | Mechanical test report: | if |

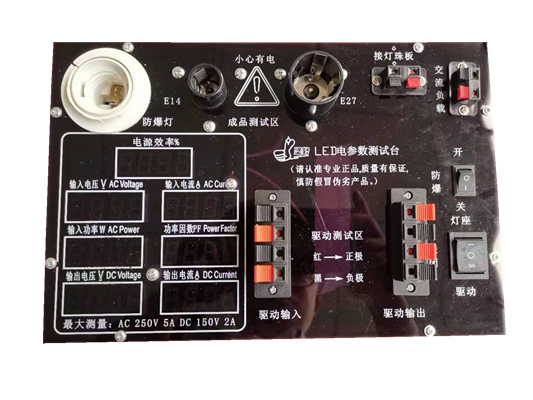

Product Description

production process:

Belt Conveying Line-Automatic Bulb Assembly Machine-Bulb Glue Punching Machine-Bulb Crimping Machine-Bulb Automatic Aging Line-Air Compressor-Bulb Tester-Bulb PCB Board Soldering Iron

Shipping and Packaging Scenarios

company environment

customer picture

Some customers

FAQ

You ask: |

1: I want to start a business, but I don't have any experience, can you help me? A: We have been engaged in the equipment industry for more than ten years, and have rich experience in LED/TV/mobile phone/power supply/refrigerator compressor factory construction. We can provide one-stop support and services from factory construction to raw material procurement to related equipment procurement to factory production . |

2: I want to start a business, but I don't have enough funds, can you help me? A: First of all, equipment with a high degree of automation may not be suitable for you, but the price is definitely expensive. We will provide the machine solution that best suits your current capacity and budget. Manual or semi-automatic machines, coupled with good production management, can also produce good products. |

3: I have been in this business for several years, but the production capacity has been low, can you help me? A: How efficient is your staff? Is your machine stable? How do you test and age your product? How is the market feedback on the quality of your products? |

4: My factory opened and the equipment was bought. Can you give me some advice for upgrading my company? A: Please send me your current production equipment pictures and on-site production video. Manual operation can be upgraded to assembly line operation, manual machine can be upgraded to semi-automatic or fully automatic machine, and single-station machine can be upgraded to multi-station machine-station machine. |

5: I bought your machine, but I can't install and operate it, can you help me? A: All equipment comes with an "Installation and Operation Manual". You can bring samples to our company for production demonstration, training how to install, operate and maintain equipment. We can also provide engineers to your factory for installation and training services. |

6: Although your engineers have completed the installation and training in our company, if there is another problem with the equipment after returning to China, how should I solve it? A: First of all, we can provide online WeChat and video remote guidance, remote modification or upgrade procedures, and air shipment of spare parts. After this series of operations, if the problem is not solved, we will send engineers to your company to provide on-site service. |

We ask: |

1: What is the product you are producing or planning to produce? 2: What is your production capacity for 8 hours? 3: What are the details of your products? 4: How do you plan your factory, which also means what machines are you going to buy? 5: What are the problems in your factory planning process? 6: When do you plan to start this project? |

Contact information

Charlie Young (Yang Chunlin) Shenzhen Castel Technology Co., Ltd. Mobile: +86 15013801065 Email: charlieyang@carstker.com WeChat/Whatsapp: +86 15013801065 QQ: 1090296323 LinkedIn: Charlie Yang URL: www.carstker.com Address: Room 201, Building A, Nandong Third Industrial Zone, Shajing Street, Baoan District, Shenzhen |

VIEW MORE

You may like

-

High quality H24 head M nozzle FUJI NXT SMT placement machine

-

SMT 750(760) four-way solenoid valve PV140507000 VQD1121W-5MO-C4-X8B

-

SMT spare partsSMT machine lead cutting X036-125

-

Radial Manual Forming Machine / Component Cutter / Component Lead Cutter

-

ARISE SE series deviation correction control system driver, stable performance, high cost performance

-

LED High Quality Lamp Cap Punching Machine LED Bulb Lamp Punching Crimping Machine Crimping Machine

-

Placement machine JUKI RS-1R SMD SMT placement machine for SMT production line PCB assembly machine

-

SMT auto loader PCB unloader for assembly line and electronics machinery

-

Fully automatic smd machine high speed automatic led light string making machine placement machine

-

SMT production line machine original second-hand CP machine inventory high second-hand SMT placement machine

Other Products

-

$220.00 - $250.00 / set

$220.00 - $250.00 / set -

$1.50 - $1.70 / set

$1.50 - $1.70 / set