Wood Chip Hot Rotary Airflow Duct Dryer CE Approved Dryer Price Biomass Dryer

-

Supplier: Tianjin Mikim Technique Co., Ltd. -

Region: Tianjin, China -

Contact: Ms Fiona Mikim -

Price: $1500.00 /set -

Min. Order: 1 set

| Video shipment inspection: | if | Core components: | motor |

| Production capacity: | 300-700kg/hour | Mechanical test report: | if |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Used for: | dry sawdust |

| Marketing Type: | normal product | name: | Sawdust Rotary Dryer |

| Warranty: | 1 year | Voltage: | custom made |

| Core component warranty: | 1 year | State of health: | new |

| Packaging Details: | Wooden Export Packaging Sawdust Rotary Dryer Biomass Dryer | Finished material humidity: | 8-12% |

| Drying material: | sawdust, wood shavings, sawdust | way to heat up: | Hot stove |

| brand: | rice gold | thing: | Biomass dryer |

| place of origin; place of origin: | China | Showroom location: | Philippines, Peru, Indonesia, Mexico, Thailand, Kenya, Chile, Colombia, South Africa |

| application: | drying sawdust | Types of: | Sawdust Dryer |

| Raw material moisture: | 30-40% | Install: | Engineer Guidance |

| weight: | 3000 kg | Applicable industries: | Building supplies store, manufacturing plant, farm, household, retail, energy and mining, food and beverage store, advertising agency |

| Heating source: | Wood, natural gas, oil, etc. |

Wood Chip Hot Rotary Airflow Duct Dryer CE Approved Dryer Price Biomass Dryer

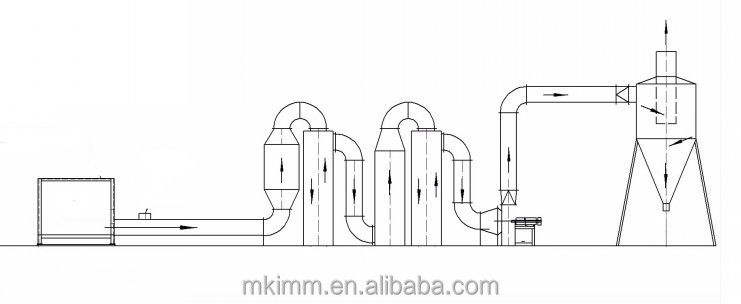

Sawdust dryer is also called pipeline dryer, wood chip flash dryer, this machine is specially designed for drying wood chips, wood shavings, wheat, straw, corn stalks and other materials.

The diameter of straw and other raw materials should be less than 3mm, and

The raw material moisture is less than 40%, and drying once can meet the requirements of the briquette production line.

Biomass Dryer Features:

² Suitable for dry materials with moisture content of 20-70%.

² Suitable for drying sawdust, rice husk, milling wheat straw, corn straw and other materials.

² Equipped with two oil-fired boilers, air inlets, steel pipes, exhaust fans (fans), air locks, and cyclone separators. Wet material enters the hopper.

² After the hot air produced by the oil-fired boiler is mixed with the wet material, it is quickly sucked into the pipeline by the exhaust fan (fan). Then the hot air flows through the curved pipe and the buffer (drying chamber) of the dryer, thus completing the drying of the wet material, and the dried material is discharged from the outlet with an air lock.

² Reduce moisture to 8-12%.

² Customers can change the angle of the dryer according to the production site.

operatePprogram:

² After the installation is complete, turn on the fan, check the rotation direction of the fan, and check whether the air suction port is normal.

² Check the flange connection for air leakage.

² Bind the bag with both ends open at the lower opening of the separator.

² Add the material to be dried at the feed port, and remove large particles before drying, which is beneficial to improve the drying speed.

² Add fuel to the stove to ignite and turn on the fan. When the temperature of the air outlet is as high as 150°C, the material is cut off and dried.

² Timely remove the bulk material at the slag outlet to facilitate feeding.

|

product |

Wood Chip Hot Rotary Airflow Duct Dryer CE Approved Dryer Price Biomass Dryer | |||

|

Model |

HG-219 |

Mercury-300 |

Mercury - 350 |

Mercury-400 |

|

initial moisture |

25%-40% |

25%-40% |

20%-40% |

20%-40% |

|

final moisture |

10%-15% |

10%-15% |

10%-15% |

10%-15% |

|

main power |

4 kW |

7.5 kW |

11 kW |

15 kW |

|

drying speed |

200-250kg/hour |

300-400kg/hour |

600-800kg/hour |

800-1000kg/hour |

|

pipe diameter |

260mm |

300mm |

350mm |

400mm |

|

Cyclone diameter |

780mm |

900mm |

1050mm |

1200mm |

|

energy burn |

40-50kg/hour |

60-80kg/hour |

80-100kg/hour |

100-150kg/hour |

|

size |

9*2.5*3.1m |

16*2.5*3.2m |

18*3*3.3m |

20*3*3.5m |

|

weight |

1760 kg |

2660 kg |

3200 kg |

4000 kg |

The role of sawdust dryer:

Ø Able to ensure the compliance rate of finished products

Ø It can solve the problem of uneven final particle size.

Ø High-tech reliability and precision

Ø Unique design, advanced diesel electric heating method

-

Long service life biomass pellet fuel drum dryer single cylinder wood chip dryer

-

500 tons per day agricultural batch corn dryer rice grain tower wheat corn dryer

-

500kg/h output dryer is suitable for rice husk, sawdust, small shavings hot air sawdust dryer

-

3 Tons Per Hour Wet Rotary Biomass Conveyor Pneumatic Ring Dryer Biomass Wood Pellet Dryer

-

Biomass pipeline hot air sawdust rice husk dryer biomass wood sawdust dryer hot air flow hot stove small sawdust dryer

-

High Efficiency Airflow Tapioca Flour Dryer/Hot Airflow Tapioca Flour Dryer For Sale

-

Airflow Dryer Sawdust Dryer

-

Efficient Wood Processing Sawdust Rotary Drum Dryer Sawdust Dryer

-

Energy saving electric dryer

-

Limited Time Offer Durable Civil Machinery Grain Dryer with Full Grain Alarm Device

Other Products

-

$500.00 / set

$500.00 / set -

$500.00 / set

$500.00 / set -

$850.00 / set

$850.00 / set