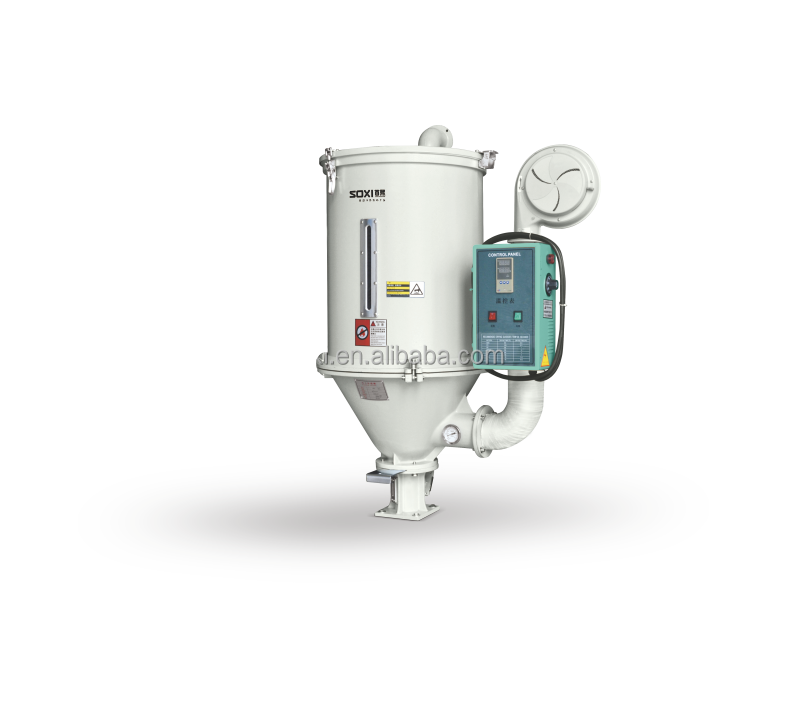

Standard Industrial High Efficiency Energy Saving Plastic Pellet Hopper Hot Air Dryer For Plastic Molding Industry

-

Supplier: Guangdong Soxi Intelligent Equipment Co., Ltd -

Region: Guangdong, China -

Contact: Mr Miny Fan -

Price: $300.00 /set -

Min. Order: 1 set

| Applicable industries: | manufacturing plant | Heater power: | 1 kW |

| After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Name: | Hot air dryer |

| Electric heating power (kW): | 1.73 kW | payment terms: | L/C, T/T |

| control: | PID controller | Hopper capacity: | 5 kg |

| Supply capacity: | 800 sets per month | Fan power (W): | 0.55 watts |

| place of origin; place of origin: | Guangdong, China | Function: | dry ingredients |

| Mechanical test report: | if | Key words: | plastic hopper dryer stainless steel |

| Capacity (kg): | 5 kg | product name: | Industrial Granule Hopper Dryer |

| Marketing Type: | New Products 2020 | Power (kW): | 1.73 kW |

| Working system: | Drying + dehumidification + loading (all | After-sales service provided: | Free spare parts, video technical support, on-site maintenance and repair services, online support, on-site installation, commissioning and training |

| brand: | Southie | Core component warranty: | 1 year |

| Video shipment inspection: | if | Package preview: | |

| Showroom location: | not any | Local service location: | not any |

| Packaging Details: | export wooden box | Weight (kg): | 150 kg |

| usage: | PE PP PET ABS PVC | application: | Colloidal particles |

| Warranty: | 1 year | Certification: | CE, ISO9001 |

| port: | Shenzhen | State of health: | new |

| Core components: | PLC, motor, heater, blower, dehumidifier |

Standard Industrial High Efficiency Energy Saving Plastic Pellet Hopper Hot Air Dryer For Plastic Molding Industry

The hopper hot air dryer can also be called an ordinary dryer, which is the most economical dryer for drying plastic raw materials. This hopper dryer can be used together with the injection molding machine, which is simple and efficient! The hopper dryer is an updated product of the standard hot air dryer, which is improved by fully considering environmental protection factors on the basis of the original functions. It dries raw materials dampened by packaging, shipping or recycling.

main feature

1. The high-performance hot air diffusion device with uniform hot air distribution is adopted to keep the plastic drying temperature uniform and improve the drying efficiency.

2. The unique design of the hot air pipe can avoid the accumulation of dust at the bottom of the electric heater and cause burning.

3. The barrel and internal parts are made of stainless steel.

4. The bottom of the barrel is separated, which is convenient for material cleaning and fast for refueling.

5. The proportional deviation thermostat can be used to control the temperature accurately.

6. Double overheating protection device can reduce accidents caused by man-made or mechanical failure.

7. Preheating timing device, microcomputer control, and double-layer insulation barrel are optional for various models.

8. Full digital PID control LED status display.

9,0-99 hours timer automatically powers on.

10. Provide intermittent drying mode to achieve the purpose of saving electricity. (8-10 SHD-DT series only)

11. Transparent window magnet base.

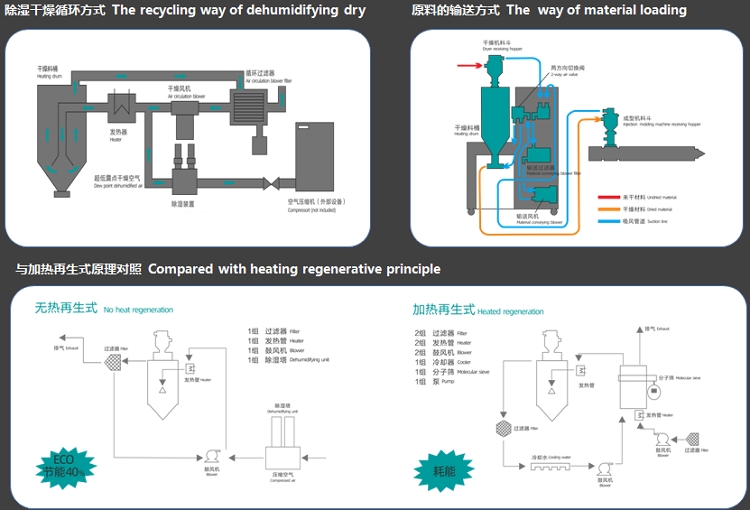

Hopper dryer working principle:

In the raw material processing process, the hopper dryer blows the constant temperature high-temperature wind into the drying barrel through the drying fan, and after the raw material is baked, the original moisture of the raw material in the barrel is taken away to achieve the purpose of drying. Remove moisture from raw materials. The air blown out by the fan becomes high-temperature dry hot air after electric heating, and the hot air is evenly distributed in the dryer through the screen protector and hole screen. Equipped with a hot air recovery device, the blown air enters the drying fan through the return air filter to form a closed loop, saving electricity.

Application fields of hopper dryer:

Hopper dryers are the most efficient and economical models for drying plastic materials, whether wet, packaged, transported or recycled. The straight-through design is especially suitable for direct installation on the plastic molding machine for drying, which is fast and space-saving. This type of blowing hot air dryer can provide a charge of 12 to 1000 kg and is divided into thirteen models.

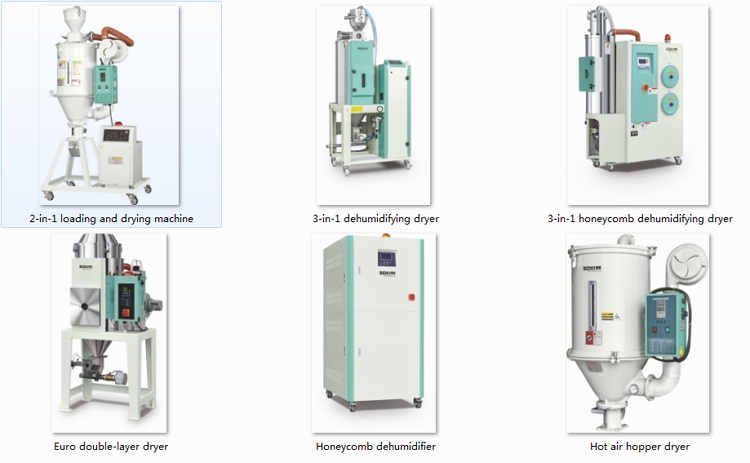

Other types of SOXI dryers

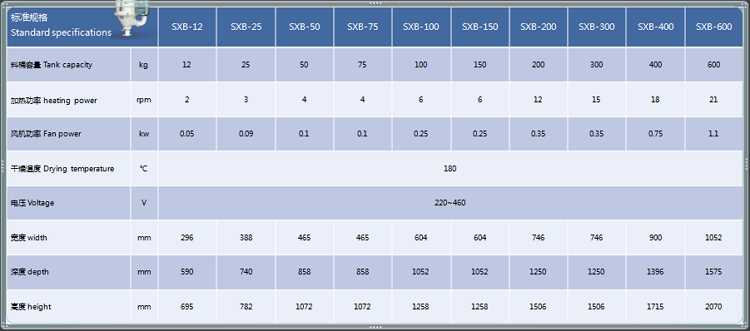

Plastic anti-crystallization hot air hopper raw material dryer specifications

Maintenance of hopper dryer:

1. Filter cleaning. The air intake filter should be checked regularly and cleaned regularly. When the filter is blocked, the air intake will decrease, which will affect the drying effect.

2. Separator cleaning: replace the raw material and wipe the separator clean

3. Cleaning of the dust collection room: During the drying process, the powdery materials falling into the dust collection room accumulate for a long time, so the drying room needs to be cleaned regularly, and the fan can be turned on and started to use wind blowing powder.

4. Screen raw material agglomeration cleaning: If the temperature is too high for some reason, the material cannot fall when the raw material agglomerates on the screen. At this time, it is forbidden to use hard objects such as iron rods to protect the filter screen separator from damage, and remove the bucket. break down.

5. Shutdown: It is very hot after switching on and off, and then turn off the fan to ensure that the heating tube is fully cooled to prolong its service life.

Installation and use of drying hopper:

1. Installation: Drill the base of the dryer, erect it on the feed port of the injection molding machine, and fix it with fastening screws.

2. Connect the power supply: open the power distribution box, connect the power supply according to the wiring diagram, pay attention to whether the power supply voltage is consistent with the local area, whether the power switch specification and load protection rating are appropriate, and start the fan to see if the rotation direction is consistent with the direction marked on the fan. There is a ground mark on the terminal bolt on the back of the electrical box, and it must be properly grounded.

3. Temperature adjustment: refer to the plastic raw material drying temperature reference table, and set the constant temperature according to actual experience.

4. Air volume adjustment: generally fully open, if the material storage hopper time is not long, or when a higher temperature is required, the air volume can be adjusted down as appropriate, otherwise the ideal drying effect will not be achieved.

5. Raw material filler: The filler should ensure that the material content is not less than 70%, but it should not be too full, so as not to press the cap and affect the drying effect.

6. Drying of transparent raw materials: To dry transparent raw materials, a filter (original sponge, etc.) must be installed at the air inlet to prevent dust in the air from entering.

7. Preheating the material barrel: Before the raw materials are put in, the material barrel is heated to dry the internal moisture, and the preheating time is 10-20 minutes.

Company Profile

Production facilities

Injection molding industry engineering case

SOXI certificate

SOXI client

-

50kg hot air plastic resin hopper dryer with automatic loader and magnetic rod manufacturing for plastic injection molding

-

Injection molding machine plastic raw material hopper dryer

-

PA PET PU TPU PC PBT PMMA CA Plastic Dehumidifier Dryer

-

Industrial Plastic Pet Computer Dehumidifier Dryer

-

Recycling Plastic Bags Hot Air Dryers Centrifugal Dehydrators Plastic Washers and Dryers

-

China New Plastic Recycling Hopper Dryer Plastic Dryer Vacuum Auto Loader With Heat Pipe

-

Plastic waste and film plastic dryers

-

High Quality Commercial Vertical Centrifugal PVC Plastic Dryer

-

25 kg plastic hopper 50 kg dryer for injection molding machine

-

Silicone Flexible Brake Hot and Cold Air Intake Pipe Duct Hose for Sale

Other Products

-

$300.00 / set

$300.00 / set -

$300.00 / set

$300.00 / set