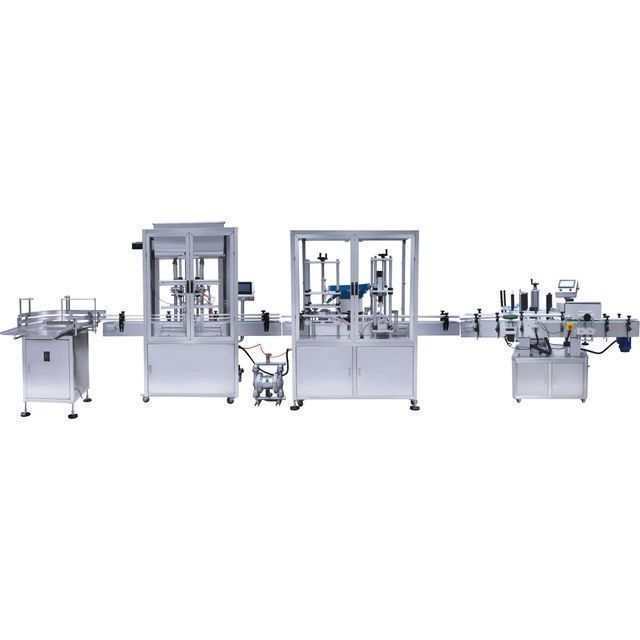

Automatic Syrup Bottle Filling Labeling Machine/Pharmaceutical Syrup Filling Product Line

-

Supplier: Shanghai Yoho Intelligent Machinery Co., Ltd. -

Region: Shanghai, China -

Contact: Mr James Chiang -

Price: $6000.00 /set -

Min. Order: 1 set

Product details

| Driver type: | electrical | application: | Food, beverage, daily necessities, medical, chemical, pharmaceutical |

| automatic: | fully automatic | Dimensions (L*W*H): | 100x100x100mm |

| After warranty service: | Video technical support, online support | Voltage: | 220/380 volts |

| Mechanical test report: | if | Core components: | Motors, PLCs, gears, engines |

| Marketing Type: | New Products 2020 | Warranty: | 1 year |

| Main selling points: | automatic | weight: | 1000 kg |

| Packaging Details: | wooden box | payment terms: | L/C, T/T, Western Union |

| Certification: | CE/SG Small | State of health: | new |

| Machine capacity: | 4000BPH, 8000BPH, Others, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH | After-sales service provided: | Online support, video technical support |

| Local service location: | not any | port: | Shanghai/Ningbo |

| brand: | Yoho | Core component warranty: | 1 year |

| Applicable industries: | Manufacturing plants, food and beverage plants, farms, restaurants, retail stores, grocery stores, food and beverage stores, advertising agencies | Supply capacity: | 100 sets per month |

| place of origin; place of origin: | China Shanghai | Video shipment inspection: | if |

| Filler: | beer, other, milk, water, oil, juice | Types of: | filling machine |

| type of packaging: | cans, bottles, barrels | Filling accuracy: | <1% |

| Showroom location: | not any | Automatic level: | automatic |

| Package preview: | Materials used for packaging: | plastic, metal, glass |

Product overview

Bottle finishing machine + automatic paste filling machine + drip cap screwing machine + automatic labeling machine

Working principle of labeling machine * Core working principle: The bottle separating wheel separates the product and puts it on the conveyor belt. The sensor detects the passing of the product and sends a signal back to the labeling control system. At the proper position, the control system controls the corresponding motor to send out the label and paste it on the product to be pasted. At the labeling position, the product flows through the labeling device, the labeling drive drives the product to rotate, the label rolls, and the labeling is completed; *Operation process: put the product (put it into the unloading box) -> separate the product and put it on the conveyor belt (the equipment automatically Realize) -> Product delivery (automatically implemented by equipment) -> Labeling (automatically implemented by equipment) -> Overlay labeling (automatically implemented by equipment) -> Collect and label products.

Fully automatic rotary capping machine XG-300 capping machine is mainly composed of several parts such as cap sorting, capping, bottle conveying, capping, lifting, conveyor belt, and rejecting mechanism. Bottle delivery is controlled via the human-machine interface. Capping speed is fast, up to 300 bottles/min. , strong adaptability, can tighten caps of different shapes, has the advantages of good sealing and good consistency. Its great advantage is that each transmission part is controlled by a separate motor, which is easy to adjust, durable and reliable. Other similar products adopt synchronous belt or sprocket transmission, which are easy to be damaged or not tightened tightly. Host equipment: Cap sorting part: The pneumatic distribution method only needs to adjust the air pressure value of each part for different caps, the replacement time is short, and the outer diameter of the cap (such as the outer diameter of 30-50mm) does not need any adjustment. Cap-dropping part: adopt slideway flipping method, the action of cap-top mechanism is controlled by optical fiber switch, and the bottle sleeve is fastened on the bottle with too spring. Bottle conveying part: The speed of the synchronous belt can be adjusted steplessly. It can be directly set digitally on the man-machine interface. The speed regulation is simple and intuitive. Capping part: Use three sets of capping wheels to rotate the cup. The three sets of capping wheels are controlled by 6 variable frequency motors, which can be independently and steplessly adjusted, and the values can be set directly on the man-machine interface. Lifting part: automatic lifting, suitable for different production lines, different bottle heights, and different bottle shapes. Transmission belt part: It is driven by plastic flat-top conveyor chain, and the speed is steplessly regulated by frequency converter. The speed and height of the conveyor belt match the conveying speed of the laminating machine. Rejecting device: controlled by optical fiber electric eye and electromagnetic induction switch, it can reject unqualified products such as feeding caps and no caps.

List of functions

The working principle of the filling machine The bottle unscrambler arranges the bottles in a row and then enters the position of the sub-packaging tray in turn, and passes through the gap of the sub-packaging tray. When the bottle stops, the filling head falls into the bottle for filling. Filling, 2 bottles at a time. The half board moves intermittently. Every time the turntable rotates 2 stations, two bottles are sent forward, and then stop to enter the gap of the splitting plate. The covers are arranged in a row by electromagnetic oscillating hoppers, and all the cover openings are covered with channels. In the guide rail, the lower opening of the cover guide rail is facing the center of the partition gap. After the bottle enters the gap of the partition, it rotates with the partition, so that the bottle mouth of each bottle takes away the bottle at the lower end of the bottle cap guide rail. Put the cap on and put it in the mouth; when the bottle with the cap enters the sealing position with the rotation of the distribution tray, the sealing seat descends, and the cap and the bottle mouth are screwed tightly. The sealed bottle will be sent to the bottle through the rotation of the aliquot plate.

filling machine

Filling and capping machine

Labeling Machine

Sales and service network

successful project

Thailand project

American project

Russian project

VIEW MORE

You may like

-

1 inch aerosol filling and capping machine with valve manual aerosol can sealing machine

-

Fully Automatic Blister Board Candy Packaging DPP-260 Alu ALu Blister Packaging Machine For Tablet Packaging

-

1-100ml small liquid, liquid detection, automatic essential oil filling and capping machine

-

Automatic Desktop Perfume Vial Filling Machine Cosmetic Cream Jar Liquid Filling Capping Labeling Machine

-

1 Inch Manual Aerosol Valve Crimping Machine

-

Fruit Juice Mango Beverage Processing Line Equipment Machinery

-

desktop filling and capping machine, small semen filling machine

-

A03 Manual Filling Machine Manual Nail Polish Shampoo Filling Machine 5~50ml for Cream Shampoo Cosmetics Liquid Paste Oil Filling Machine

-

desktop filling and capping machine, small semen filling machine

Related Search

manual bottle sticker labeling machine

beverage filling production line

automat soft drink fill and cap machin suppliers

bottle filling machine

labelling machine for round bottles

bottle labeling machine

automatic labeling machine

2016 manual square bottle labeling machine

simple manual handy round bottle labeling machine

automatic labeling machine cost